Radiating fin and fin component

A technology of heat dissipation fins and components, which is applied to parts of instruments, cooling of instruments, instruments, etc., can solve the problems of low heat absorption efficiency and achieve high heat absorption efficiency and simple structure of heat dissipation fins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

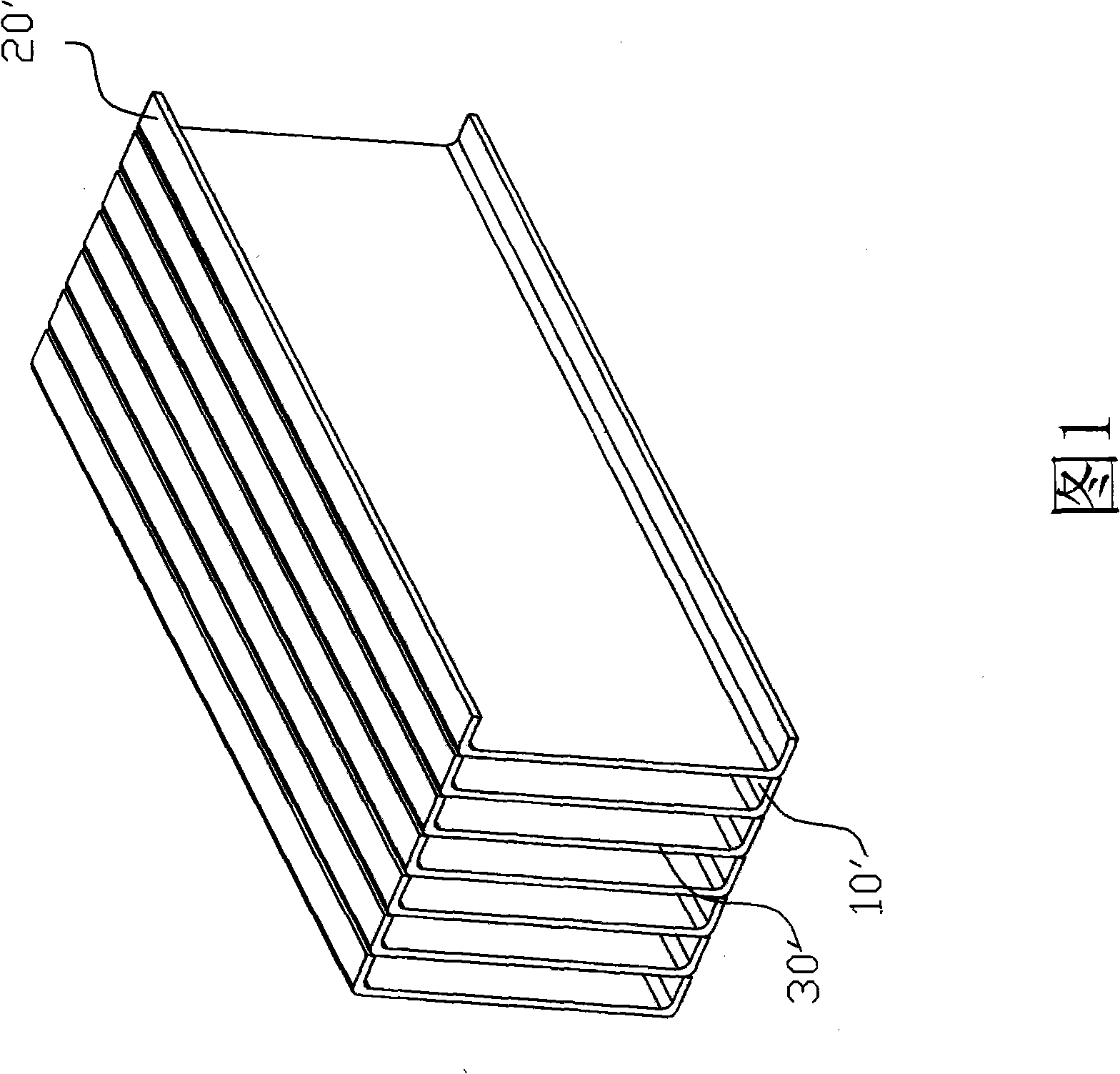

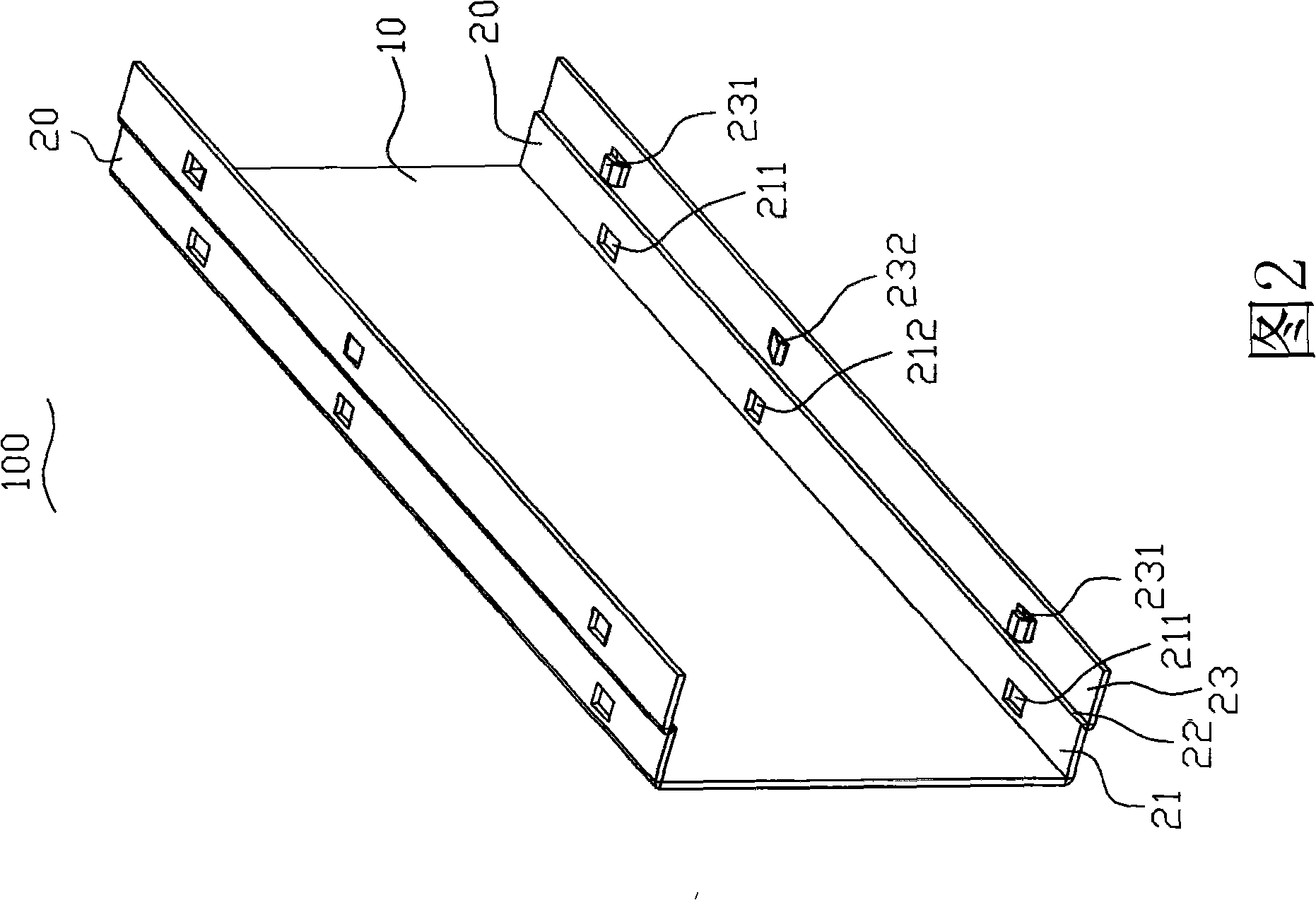

[0016] Please refer to Figure 2 and image 3 As shown, the first embodiment provides a heat dissipation fin 100 with a symmetrical structure (the heat dissipation fin 100 can also be arranged in an asymmetric structure), and the heat dissipation fin 100 includes a body 10; two sides of the body 10 A buckling portion 20 is symmetrically provided, and the buckling portion 20 includes a first bent portion 21, one side of the first bent portion 21 is vertically arranged on one side of the body 10, and the first bent portion 21 is provided with There are two clamping holes 211 (the number of clamping holes 211 is determined according to actual needs, which can be 1, 2 or more) and a limit hole 212 (the number of limit holes 212 is determined according to actual needs, which can be 1 or 2 or more), in this embodiment, the clamping hole 211 and the limiting hole 212 are arranged on the same straight line; and the other side of the first bending portion 21 is vertically provided with o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com