Multifunctional general-purpose coal fines combustion test apparatus and method

A technology of pulverized coal combustion and test device, which is applied in the field of metallurgy to achieve the effect of stable and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

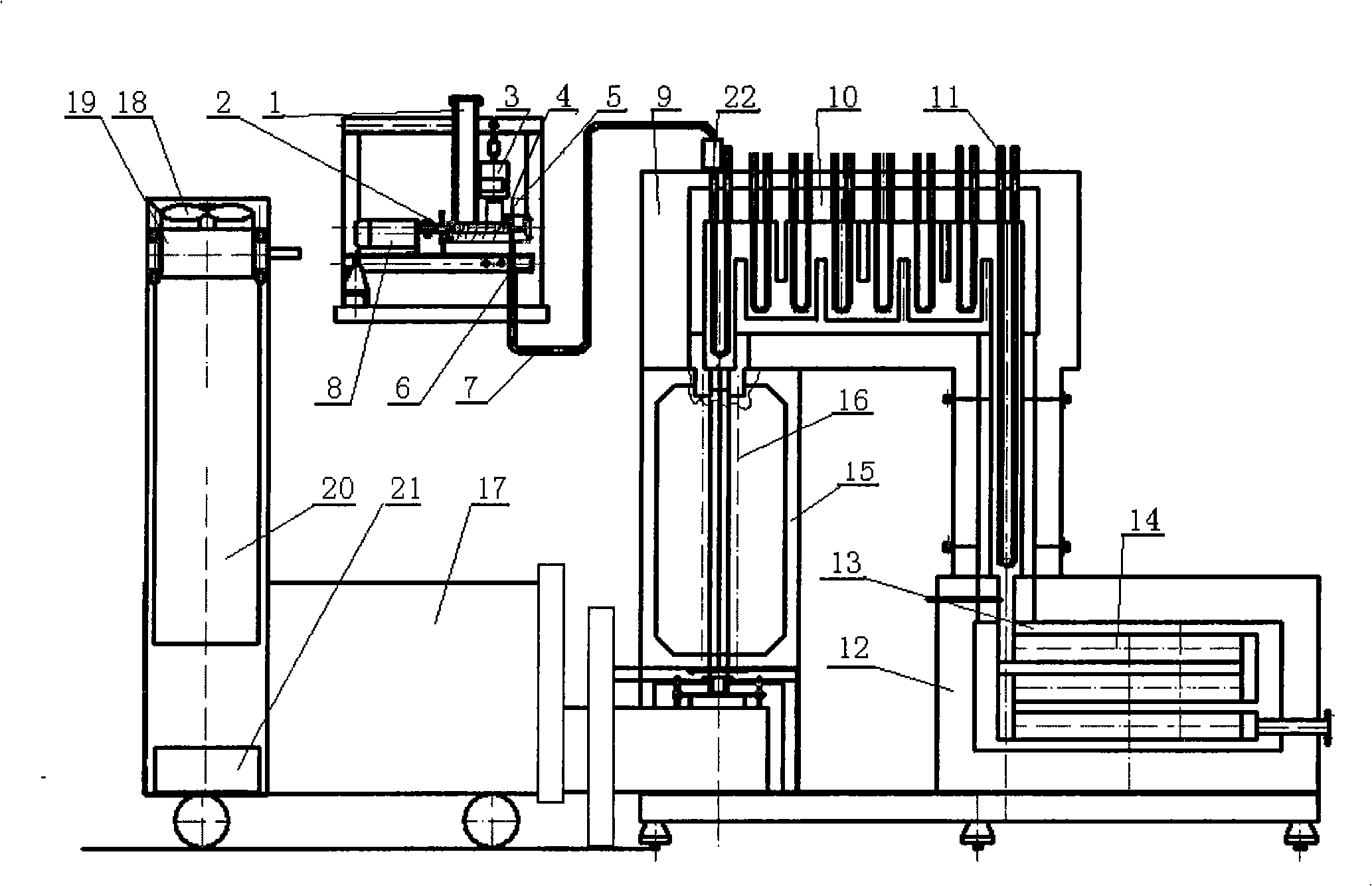

[0061] The multifunctional universal pulverized coal combustion test device of the present invention is as figure 1 As shown, the multifunctional universal pulverized coal combustion test device includes an air supply system, a gas heating system, a pulverized coal injection system, a pulverized coal combustion system, and a dust collection system.

[0062] The gas heating system consists of a low-temperature gas heating furnace 12 and a high-temperature gas heating furnace 9, and the two furnace bodies are connected in series. Among them, the gas low-temperature heating furnace 12 has a built-in gas low-temperature heating pipeline 13 and a low-temperature heating element 14, and the gas high-temperature heating furnace 9 has a built-in gas high-temperature heating pipeline 10 and a high-temperature heating element 11. The heating element of the low-temperature heating furnace is made of iron-chromium-aluminum wire. The material of the heating element of the high-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com