Large caliber vortex shedding flowmeter

A vortex flowmeter, large-diameter technology, applied in the direction of volume/mass flow generated by mechanical effects, dynamic effects by detecting fluid flow, etc., can solve the problems of low detection accuracy and poor signal, and achieve high measurement accuracy and frequency. High and low cost of installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

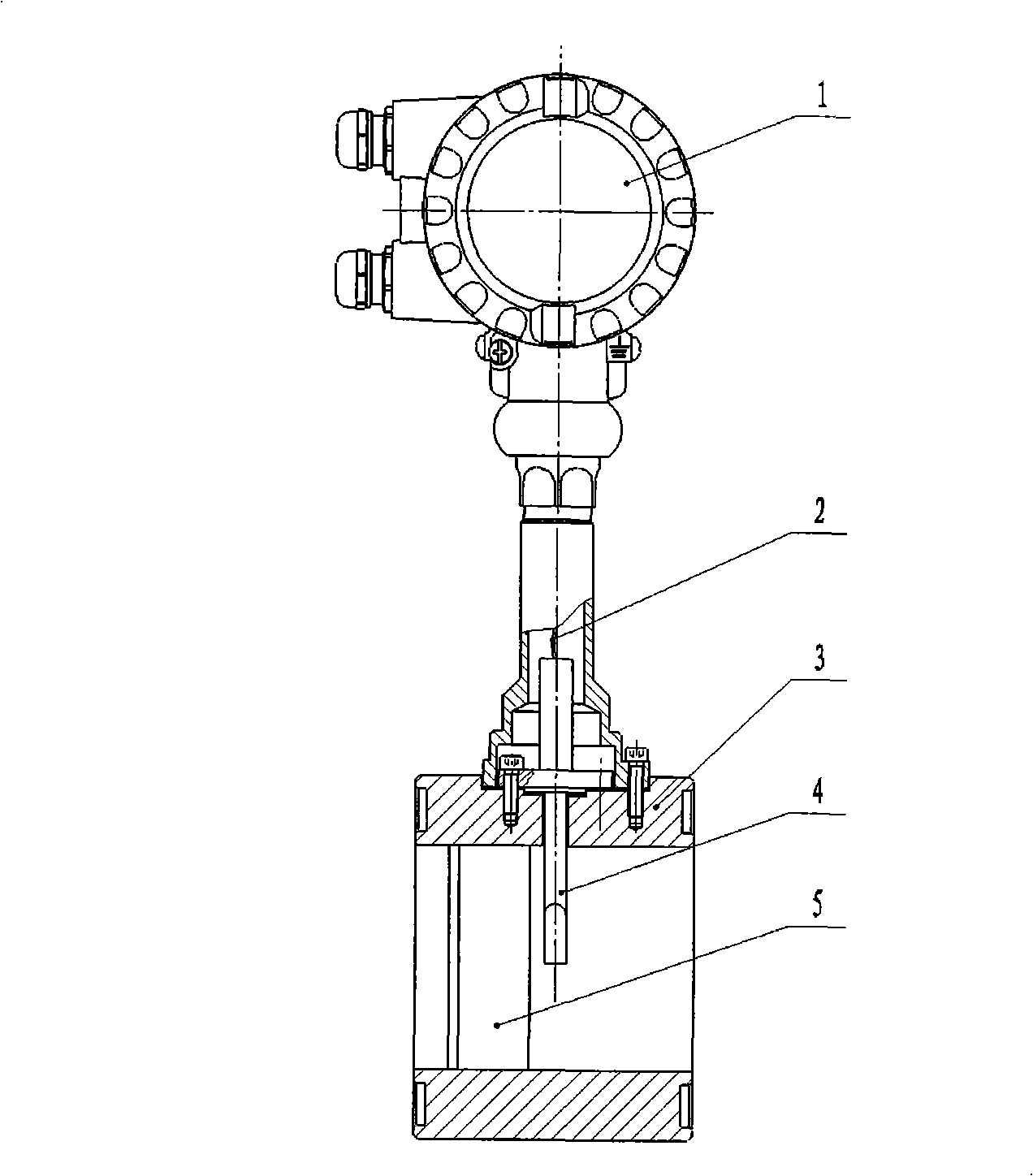

[0024] figure 2 It is a schematic diagram of the general structure of an existing vortex flowmeter, mainly composed of a small measuring tube 3, a triangular cylinder 5, a detection probe 4, a signal processing converter 1, and a signal line 2 connected to the signal processing converter 1, etc.

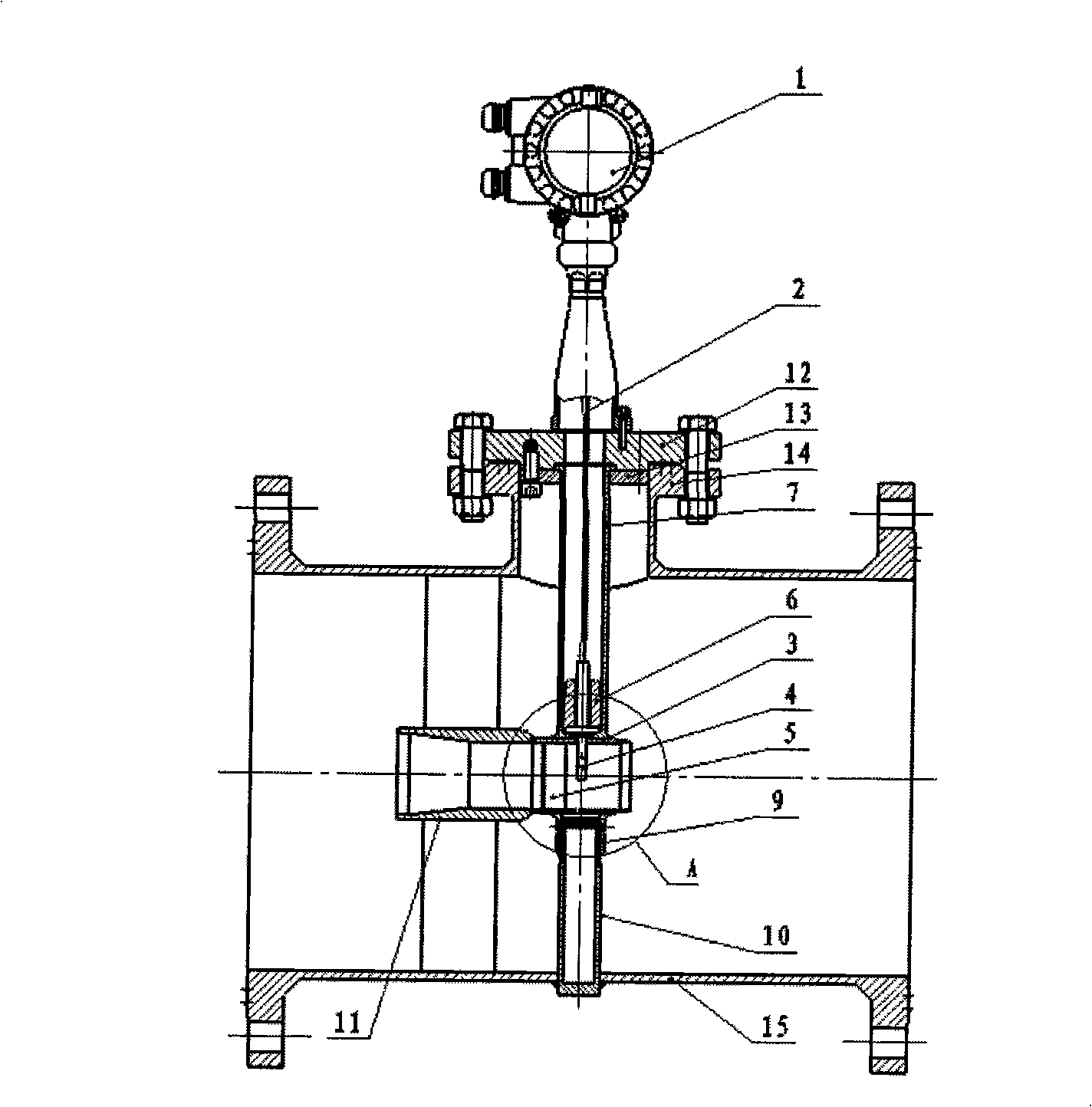

[0025] see Figure 3-1 and Figure 3-2 The vortex flowmeter comprises a large-bore measuring tube 15 and a small-bore vortex flowmeter, and the small-bore vortex flowmeter is inserted into the large-bore measuring tube 15. The specific installation method is to connect the connecting flange 12 of the small-diameter vortex flowmeter with the connecting flange 14 of the large-diameter measuring tube through bolts and nuts.

[0026] In order to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com