Anode with gas exhausting hole for aluminum electrolysis

A vent hole and aluminum electrolysis technology, which is applied in the field of improvement of the internal shape and structure of the anode block, can solve the problems of increased tank resistance, increased tank voltage, and increased power consumption, and can reduce the set voltage and working voltage, The effect of reducing power consumption and avoiding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

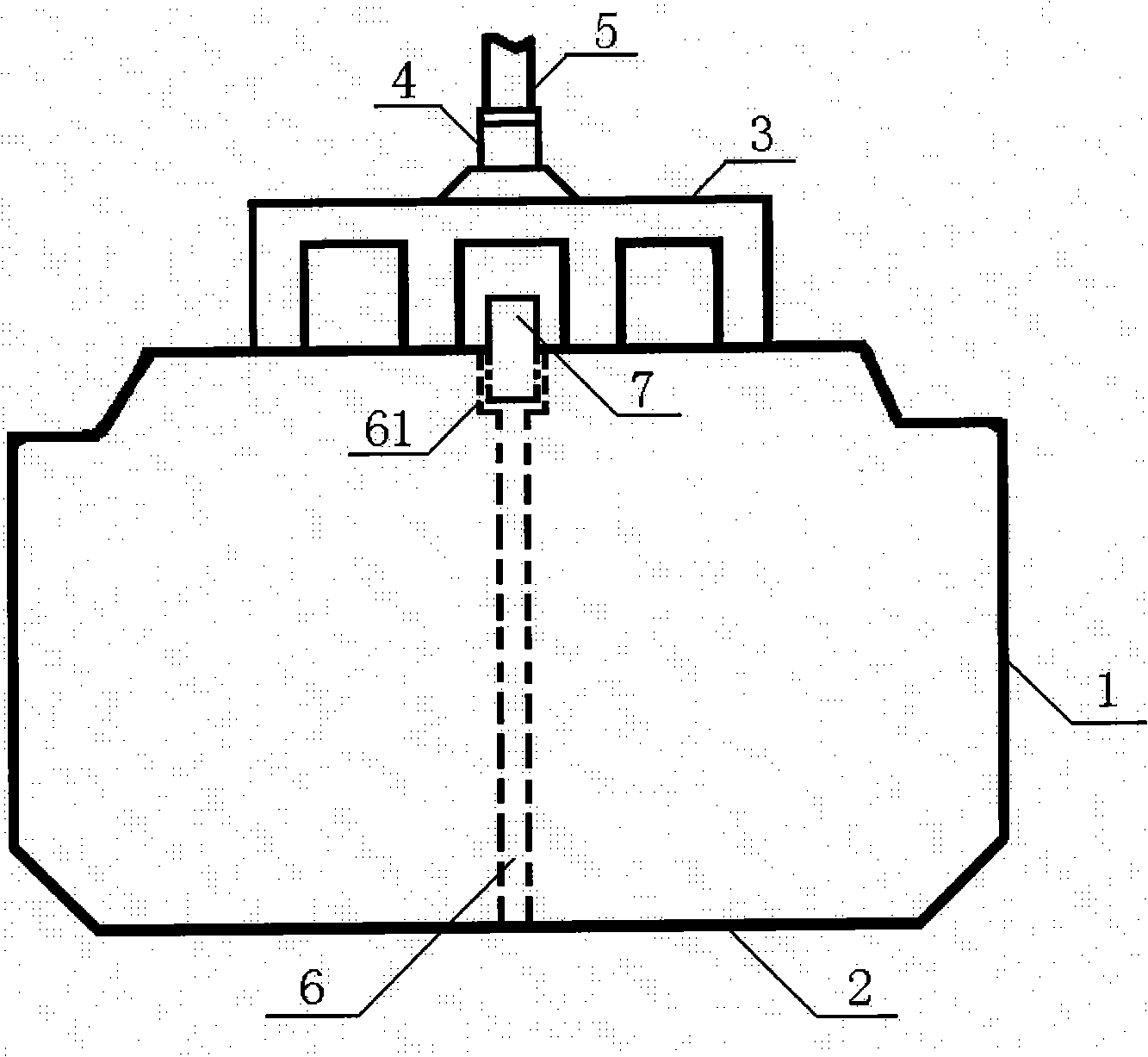

[0016] Embodiment 1: as figure 1 As shown, the anode carbon block 1 is a tetragon, the bottom surface 2 is a plane, and the top surface is embedded with a steel claw 3. The upper part of the steel claw is provided with an explosion block 4 and a guide rod 5, and a vertical anode block is produced near the center of the anode block. Cylindrical exhaust hole 6, the aperture of the exhaust hole can be selected from 0.3 to 10 centimeters, the preferred range is 1 to 7 centimeters, and the best is 5 to 6 centimeters; the exhaust hole can be selected as a through hole, which can be a vertical through hole , also can be the oblique through hole that forms a certain angle with vertical line; Exhaust hole is the half through hole that does not lead to bottom palm, and the bottom of half through hole is 1~10 centimeters apart from the bottom of bottom palm. The cross-section of the exhaust hole can be a cylindrical hole with the same or different geometric dimensions; it can also be one...

Embodiment 2

[0018] Embodiment 2: as figure 2 As shown, since the anode is piled with 10-20 cm thick surface shell covering material, in order to prevent the covering material from falling into the vent hole and causing blockage, a placement hole 61 is provided on the top of the vent hole, and placed in the placement hole There are non-metallic pipes (or metal pipes) 7 with high temperature resistance and oxidation resistance, so as to form air flue, and then add surface shell fragment covering material around the pipes. The pipe can be pressed with alumina and binder, and then used as alumina raw material and put into the electrolytic cell for use. The pipes can also be made of carbon material, but can also be made of other materials.

[0019] In the present invention, the exhaust hole can be a through hole up and down. For the convenience of one-time molding and manufacturing, it can also be a half-through hole that is connected from the top to the bottom. 30 cm, the preferred range i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com