Concave type roll bending transportation carrier

A technology for transporting racks and rolling plates, applied in the field of transport racks, can solve the problems of cumbersome and laborious operation, unstable fixing, security threats, etc., and achieve the effects of simple and labor-saving operation, stable fixing method and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

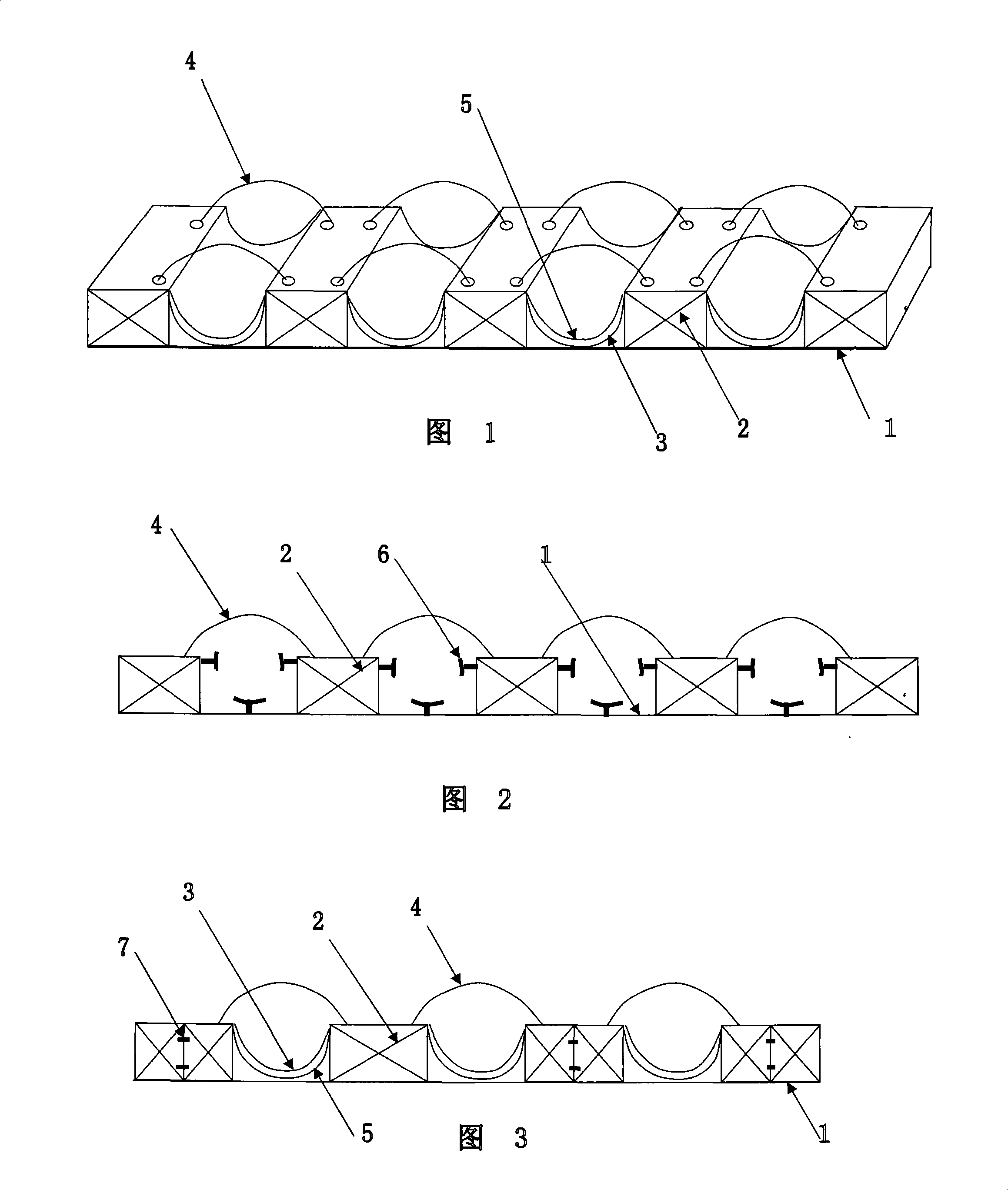

[0017] Embodiment 1. Referring to FIG. 1 , the transport frame is mainly composed of a bottom beam 1 , a support frame 2 , an arc concave 3 and a binding rope body 4 . The frame material of the bottom beam 1 and the support frame 2 can be channel steel, or high mechanical strength plastic or other materials with light weight and high mechanical strength. The support frame in the support frame 2 is a scissor brace, because the scissors brace has good stability and saves materials. The support frame 2 can be fixed on the bottom beam in a detachable manner, or can be directly fixed on the bottom beam by welding. The material of the arc-shaped concave 3 is a steel plate or other plates, and it is fixedly connected with the bottom beam 1 and the support frame 2 . The upper surfaces of several arc-shaped concave 3 and several supporting frames 2 on the transport frame can be formed by pressing a whole steel plate, which can make the transport frame have excellent tensile strength. ...

Embodiment 2

[0018] Embodiment 2: Referring to FIG. 2 , the transport frame is mainly composed of a bottom beam 1 , a support frame 2 , a support frame 6 and a binding rope body 4 . The frame material of the bottom beam 1 and the support frame 2 can be channel steel, or high mechanical strength plastic or other materials with light weight and high mechanical strength. The support frame in the support frame 2 is a scissor brace, because the scissors brace has good stability and saves materials. The support frame 2 can be fixed on the bottom beam in a detachable manner, or can be directly fixed on the bottom beam by welding. Three supporting frames 6 are provided between every two supporting frames 2 , one is provided on the bottom beam 1 , and the other two are respectively provided on the upper part of the side walls of the two interphase supporting frames 2 . The support frame 6 is a retractable structure, and its length is adjusted according to the diameter of the transported cylindrica...

Embodiment 3

[0019] Embodiment 3: Referring to FIG. 3 , the transport frame is mainly composed of a bottom beam 1 , a support frame 2 , an arc-shaped concave 3 and a binding rope body 4 . The frame material of the bottom beam 1 and the support frame 2 can be channel steel, or high mechanical strength plastic or other materials with light weight and high mechanical strength. The support frame in the support frame 2 is a scissor brace, because the scissors brace has good stability and saves materials. The support frame 2 can be fixed on the bottom beam in a detachable manner, or can be directly fixed on the bottom beam by welding. The support frame 2 has two forms, one is integral; the other is combined, that is, it is composed of two small support frames connected by a connecting piece 7, and the connecting piece 7 is a connecting bolt or other connecting piece. Each small support frame can also be connected by snap connection. The combined support frame 2 can make the transport frame len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com