Continuous media web heater

A technology for heating controllers and media, applied to instruments, equipment for electrical recording processes using charge patterns, printing, etc., can solve problems such as smearing or offset, scraping or peeling, ink not curing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] For a general understanding of the present embodiment, reference is made to the accompanying drawings. In the drawings, like reference numerals are used to designate like elements throughout the figures.

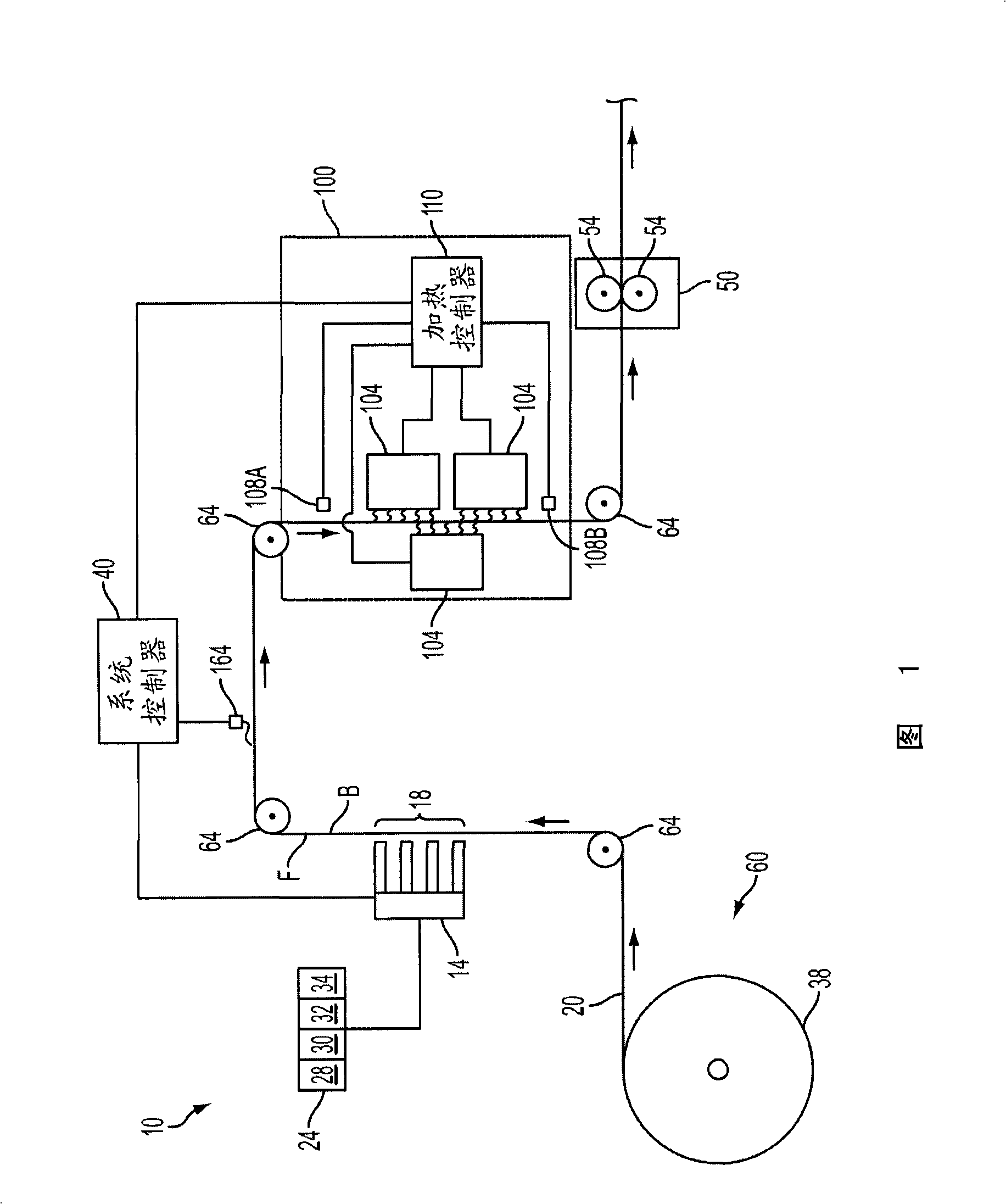

[0021] Figure 1 schematically illustrates an imaging device 10, or at least a portion of an imaging device 10, showing elements relevant to the present disclosure. In the illustrated embodiment, imaging device 10 implements a solid ink printing process to print on a continuous web of media. To this end, imaging apparatus 10 includes a web supply and handling system, a phase change ink printing system, and a web heating system. Although the web heating system is described as being used in a phase change ink imaging device, the web heating system can be used in any of a variety of other imaging devices including, for example, laser printers, facsimile machines, copiers or capable of applying one or more colorants Any other imaging device applied to a continuous web of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com