Semi-artificial cultivated diamondback moth feed and method of preparing the same

A semi-artificial technology for diamondback moth, applied in the field of feed for artificially cultivated insects, can solve the problems of irregular developmental period, difficulty in normal pupation and emergence, slow development of diamondback moth larvae, etc. Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

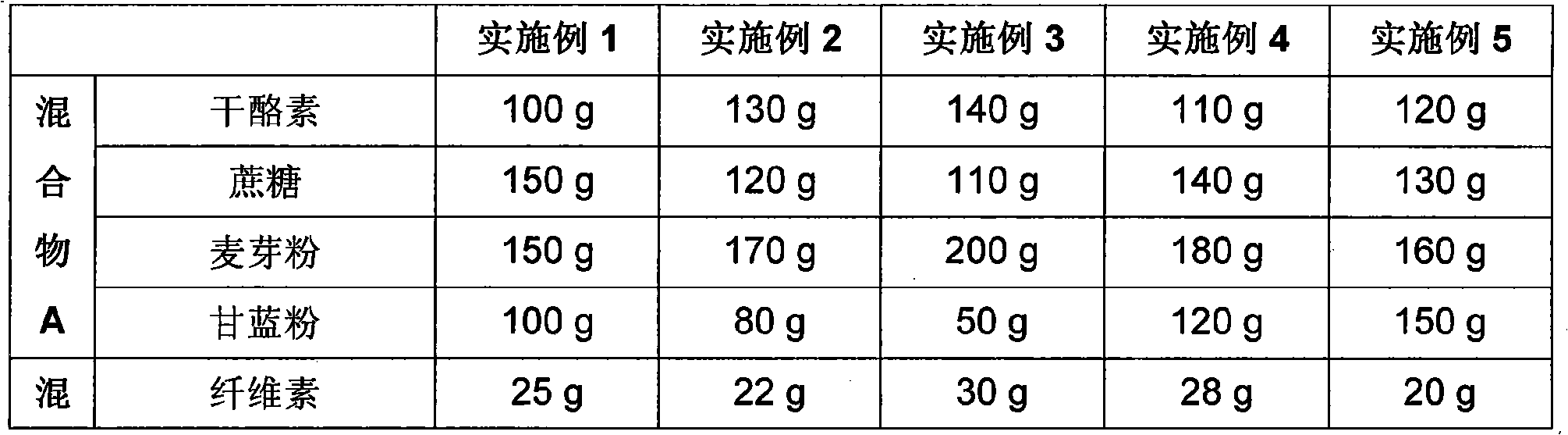

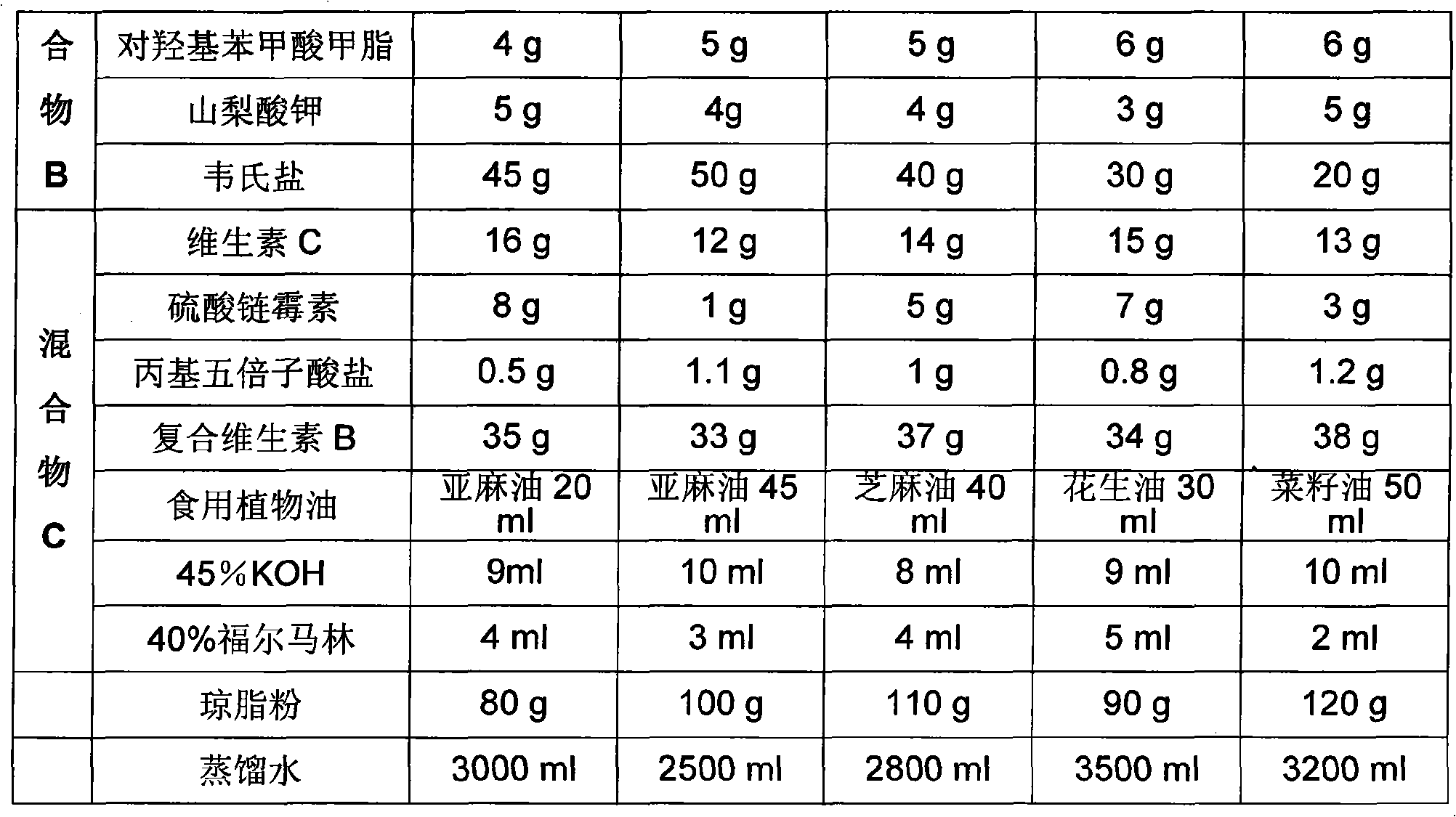

[0025] Prepare according to the table:

[0026]

[0027]

[0028] Among them, malt powder and cabbage powder are ground to 100 mesh after drying fresh malt or cabbage leaves.

[0029] The preparation method of the feed of semi-artificial culture diamondback moth, is the following steps:

[0030] (1) Weigh the ingredients according to the above formula, put them into three containers according to the ingredients of mixture A, mixture B, and mixture C, and mix the ingredients fully to form mixture A, mixture B, and mixture C;

[0031] (2) Take about five-sixths of the total amount of distilled water and agar powder into a stainless steel container, heat not higher than 90°C, and stir well until completely melted into agar liquid;

[0032] (3) Pour the mixture A into the prepared agar liquid and stir it for 30 seconds until it is uniform; then add the mixture B and stir it for 30 seconds until it is uniform, add the remaining distilled water, and when the temperature drops...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com