Method for setting feed amount of multi-level code disc used for NC-plain compatible machine tool with multiple operation modes

A feed, binning technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of high requirements of CNC lathes, limit the large-scale promotion of CNC lathes, etc., and achieve the effect of high man-machine function and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The numerical control lathe of the present invention uses the method for setting the feed rate with a step-by-step code disc,

[0031] (1) Input the feed amount parameter 1-3 of the machine tool into the feed amount database 1-4, and input the feed amount database 1-4 into the numerical control system 1-1 of the numerically controlled lathe through the data interface 1-2;

[0032] Input the six feed rate modes of ordinary lathes, longitudinal feed rate, lateral feed rate, metric thread, inch thread, modulus thread, diameter pitch thread, and detailed feed parameters into database 1-4, and this database 1-4 Input the numerical control system 1-1 of the numerical control lathe through the data interface 1-2.

[0033] (2) Distribute the parameters of each mode in an 8×8 matrix table.

[0034] (3) Set a sub-level code disc 1-6 for the selection of feed rate parameters on the operation panel provided on the machine tool. There are scales on the sub-level code ...

Embodiment 2

[0041] Embodiment 2: Use the method of setting the feed amount in steps with two step-by-step code discs in the numerical control lathe of the present invention.

[0042] Its main steps are the same as above, the difference is that there are two sub-level code discs.

[0043] Each division of the first 8-digit sub-division code wheel 1-6 corresponds to one of the six feed parameters in the database. When an 8-digit sub-division code disc is selected, the real-time display on the display is arranged in a matrix. An 8×8 matrix arrangement table of such feed parameters.

[0044] Each division of the second 64-bit division code disc corresponds to a feed parameter arranged in a matrix.

[0045] The specific operation steps are as follows:

[0046]First of all, toggle the stepped / stepless switch to the stepped state, and activate the feed parameter to control the step dial switch. Call out the thread database; dial the first 8-digit sub-code disc, and select an 8×8 thread pitch ...

Embodiment 3

[0051] Embodiment 3: The method for setting the feed rate with three sub-grade turntables for the CNC lathe of the present invention,

[0052] See Fig. 3, its main steps are the same as example 1, the difference is that three 8-bit sub-level code discs are provided.

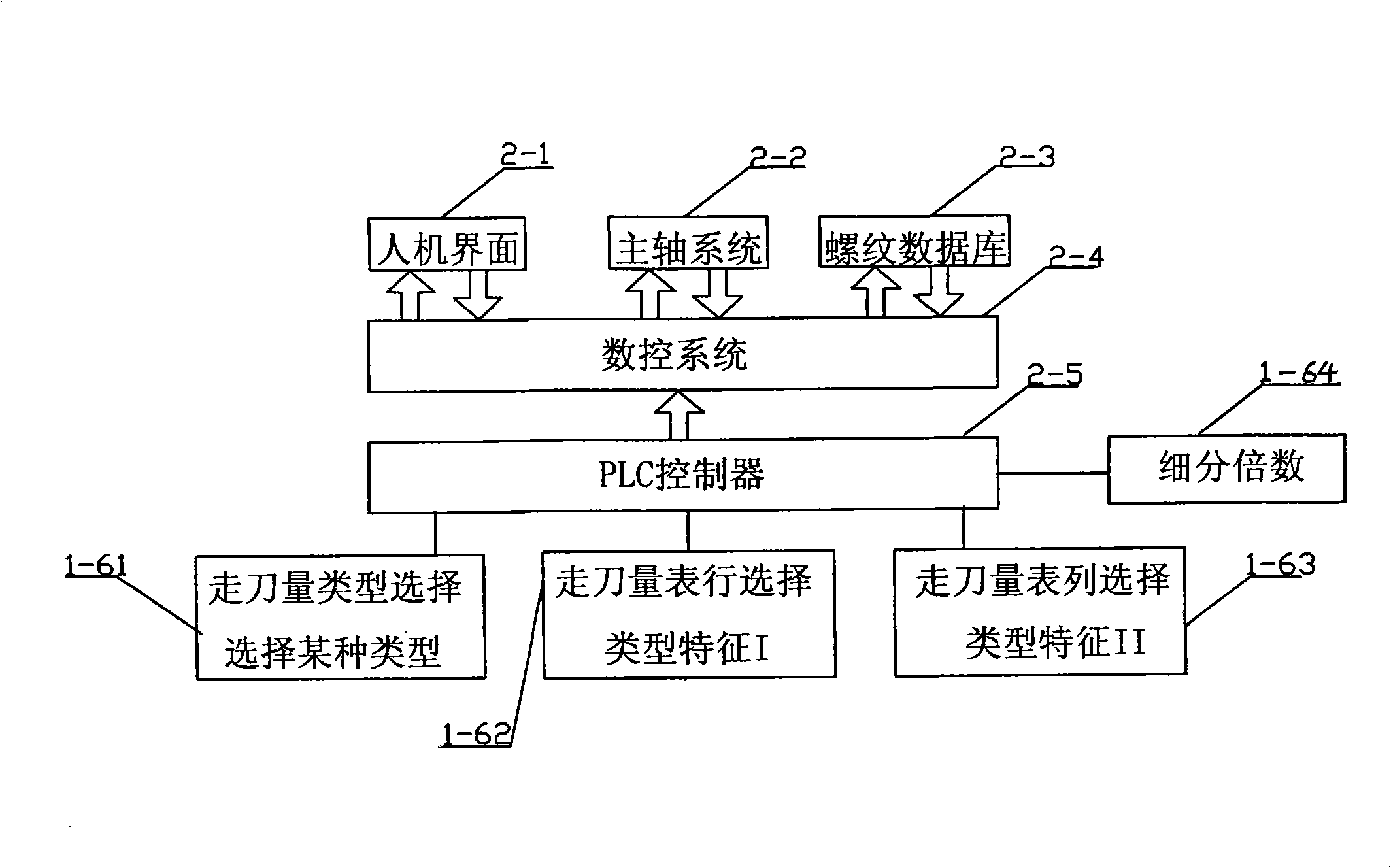

[0053] The program block flow chart of the present invention. Man-machine interface 2-1, spindle system 2-2, thread database 2-3 connected to data system 2-4; 3 sub-level code discs, the first sub-division code disc 1-61 is for the selection of the type of cutting amount, Each bin corresponds to a type of feed parameter in the database, and the man-machine interface 2-1 displays a feed parameter arranged in a matrix in real time; the second bin code disc 1-62 , for the line selection of the feed amount table, and each sub-level corresponds to a row in a feed amount parameter arranged in a matrix; the third sub-level code disc 1-63 is for the selection of the feed amount table column, Each sub-level corresponds ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com