Calibration method for moisture instrument

A calibration method, the technology of the moisture meter, applied in the direction of removing certain components and weighing, etc., can solve the problems of unsuitable grouping processing technology, etc., to achieve the effect of convenient dynamic calibration, increasing sample volume, and improving calibration efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

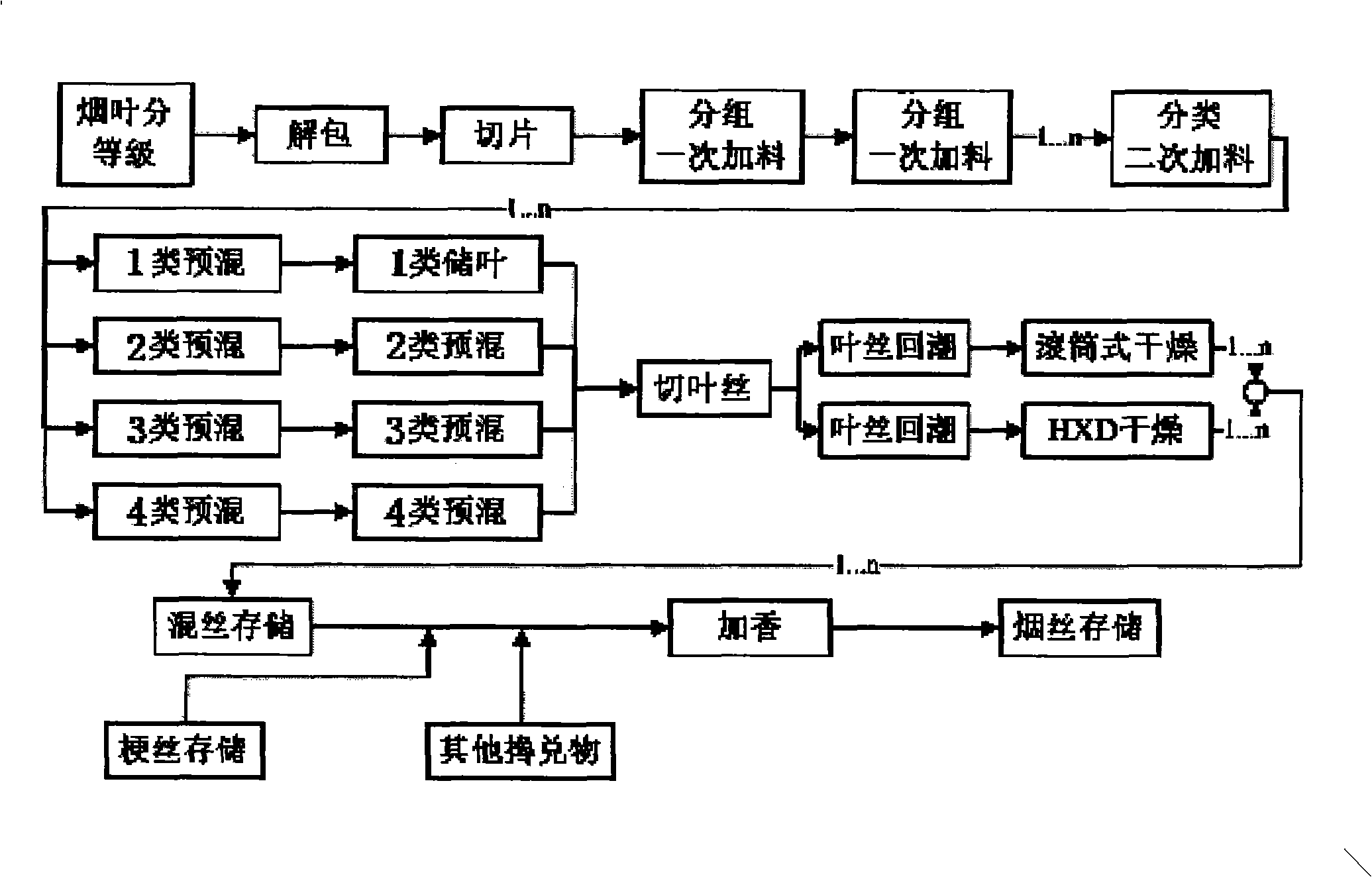

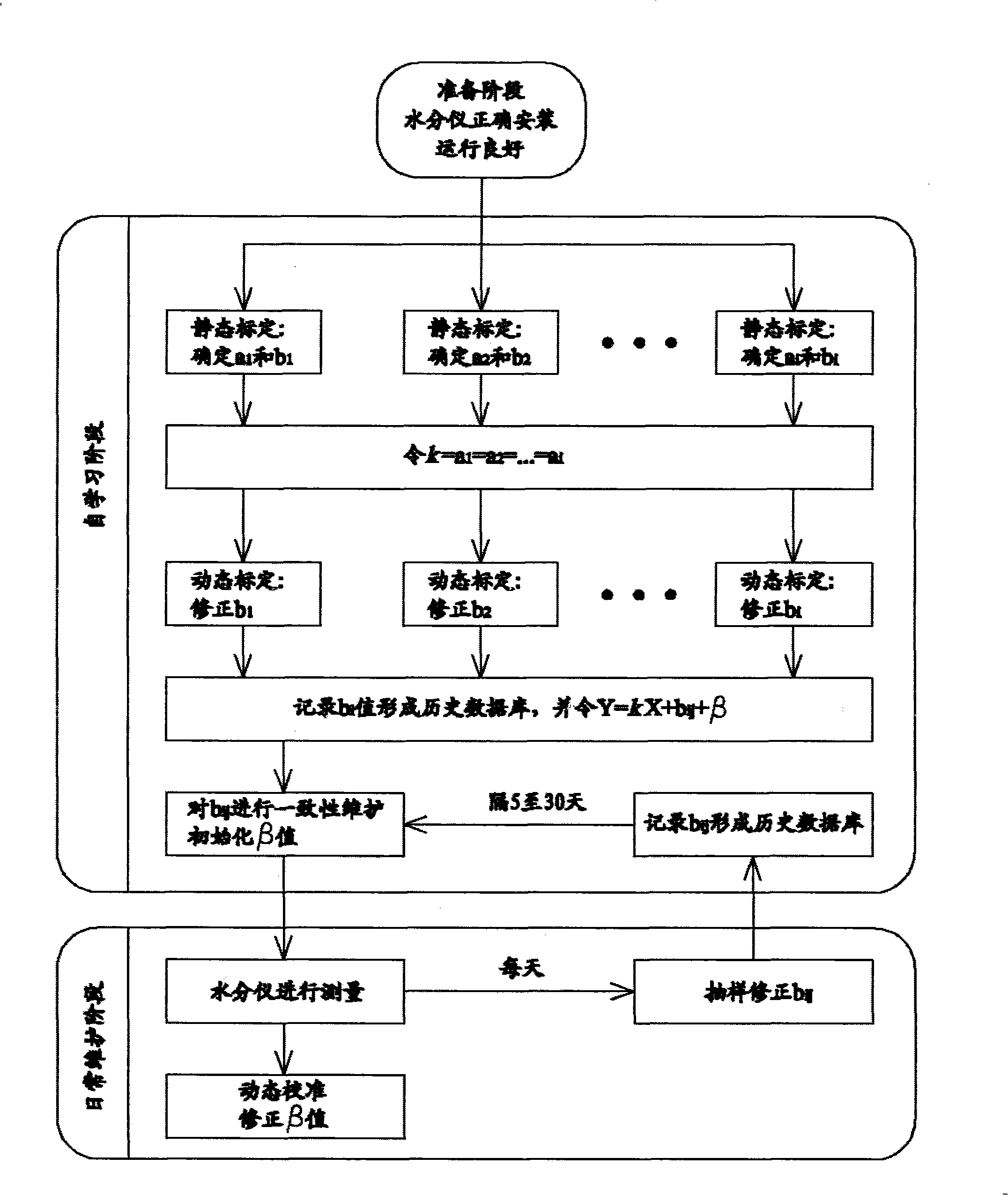

[0032] The present invention will be further described in detail by taking the cigarette grouping processing technology as an example below in conjunction with the accompanying drawings.

[0033] The grouping processing technology of cigarettes refers to the targeted formulation of suitable processing parameters and process routes for raw materials of different qualities, types, and characteristics, based on the results of process evaluation and demonstration, combined with product design requirements and sensory evaluation results of single-grade raw materials , processing methods, and the characteristic technology of Chinese cigarettes to improve the level of online processing technology. The grouping processing technology of silk production line mainly includes grouping processing of blades, grouping processing of leaf shreds and mixing of leaf shreds, etc.

[0034] Such as figure 1 As shown, there are multiple individual process points, such as loosening and rehydration, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com