Plane sliding window

A sliding window and plane technology, which is applied in the direction of the arrangement of the wings and leaves, can solve the problems of the bottom edge of the window frame being worn, poor sealing, and affecting the appearance, and achieve the effect of good sealing performance, good stability, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

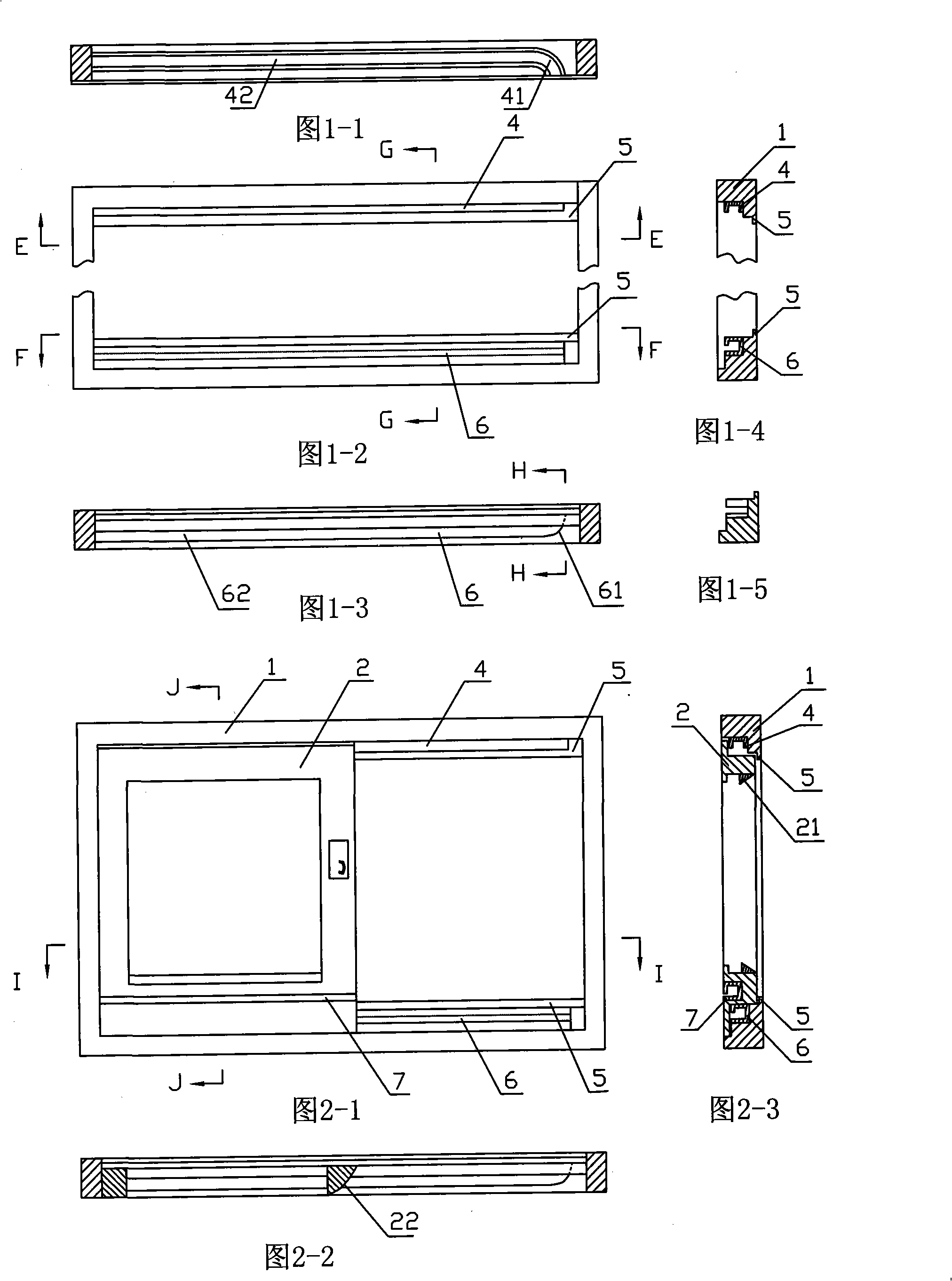

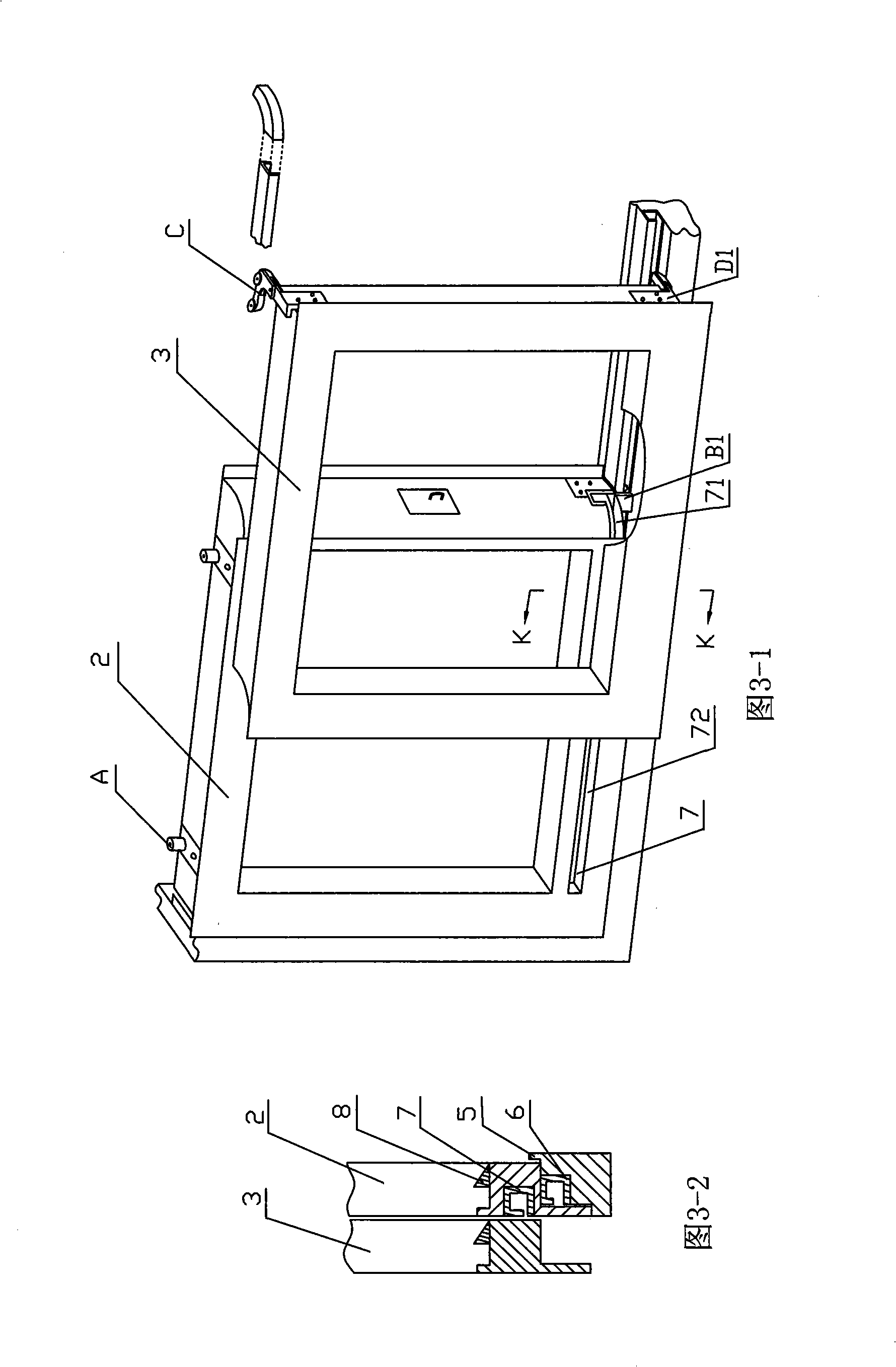

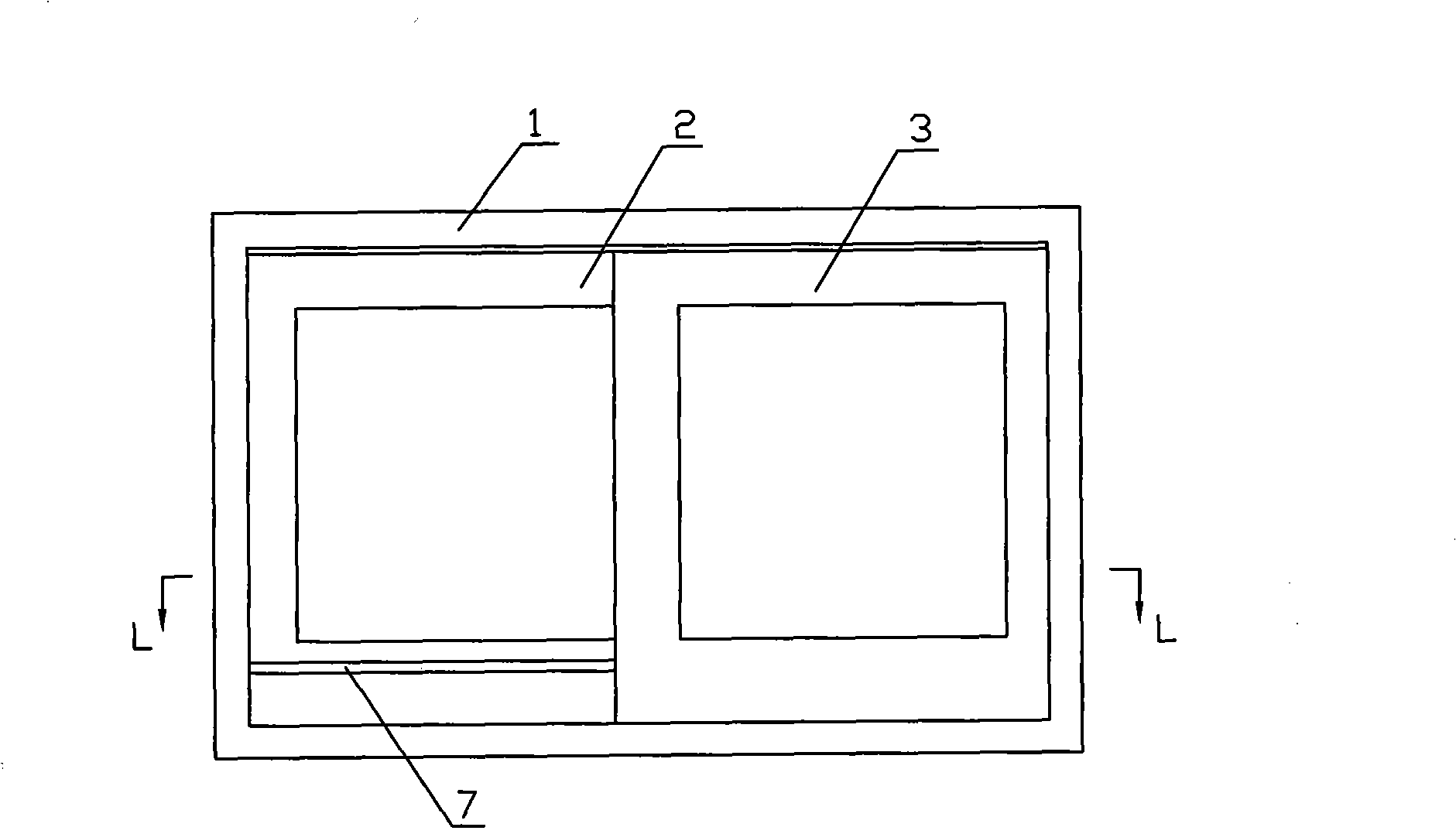

[0051] A plane sliding window, comprising a window frame and a window sash, the upper and lower beams of the window frame are respectively provided with upper and lower rails 4, 6, and the upper rail 4 and the lower rail 6 respectively have arc segments 41, 61 at the end close to the installation of the sliding sliding window sash, The end of the arc segment is about 3cm away from the vertical edge of the window frame (see Figure 1-1 and Figure 1-3). The window sash includes direct push sash 2 and translational push-pull sash 3. When the window is closed, the direct push sash and the translational push-pull sash On the same vertical plane, its butt end faces 22 and 32 are respectively circular arc surfaces (see Pic 4-1 , Figure 4-2 ), an auxiliary track 7 is arranged on the lower horizontal frame of the direct push window sash, and the auxiliary track extends to the arc end face 22 of the direct push window sash to form an arc segment 71, and a pulley A is installed on the to...

Embodiment 2

[0059] A flat sliding window, the basic structure of which is the same as above, the difference is that the cross-section of the lower rail 6 installed above the lower beam of the window frame is an inverted "∏" shape, the opening is upward, and the sliding assembly at the bottom of the sash is pushed directly at this time You only need to use ordinary pulleys, so the installation is relatively simple, but it brings some troubles to the cleaning of the track.

Embodiment 3

[0061] The utility model relates to a combined plane sliding window. It uses the plane sliding window described in Embodiment 1 of the present invention as a window unit, a balcony or other large windows made by combining multiple window units, and one or two sliding sliding windows on both sides of a direct pushing window sash can also be used. Arbitrarily assembled in the manner, the structure of each direct push sash, translational push-pull sash and the corresponding window frame, upper and lower tracks, and auxiliary track structures are the same as those in Embodiment 1, and will not be repeated here.

[0062] As a transformation of the embodiment of the present invention, the auxiliary track 7 on the lower frame can also be directly arranged on the lower frame of the direct push sash, that is, the auxiliary track 7 is a horizontal line opened on the lower frame of the direct push sash. The long groove in the direction, the long groove is extended to the circular arc end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com