Method for filling highroad roadbed by waste steel slags

A technology for filling roadbeds and steel slags, applied in roads, excavations, roads, etc., can solve problems such as lack of perfect methods, and achieve the effects of promoting environmental protection, stable and reliable roadbeds, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

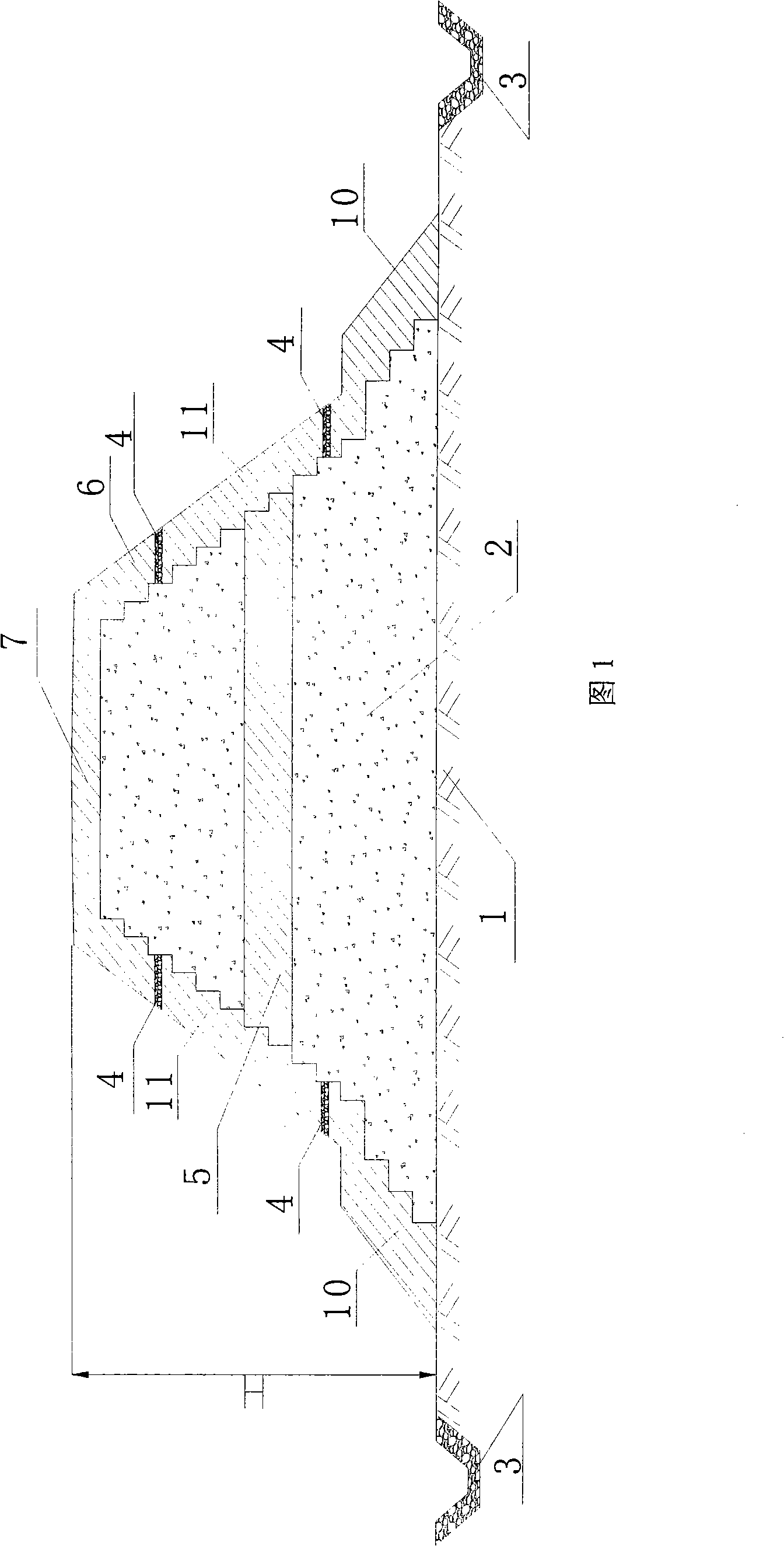

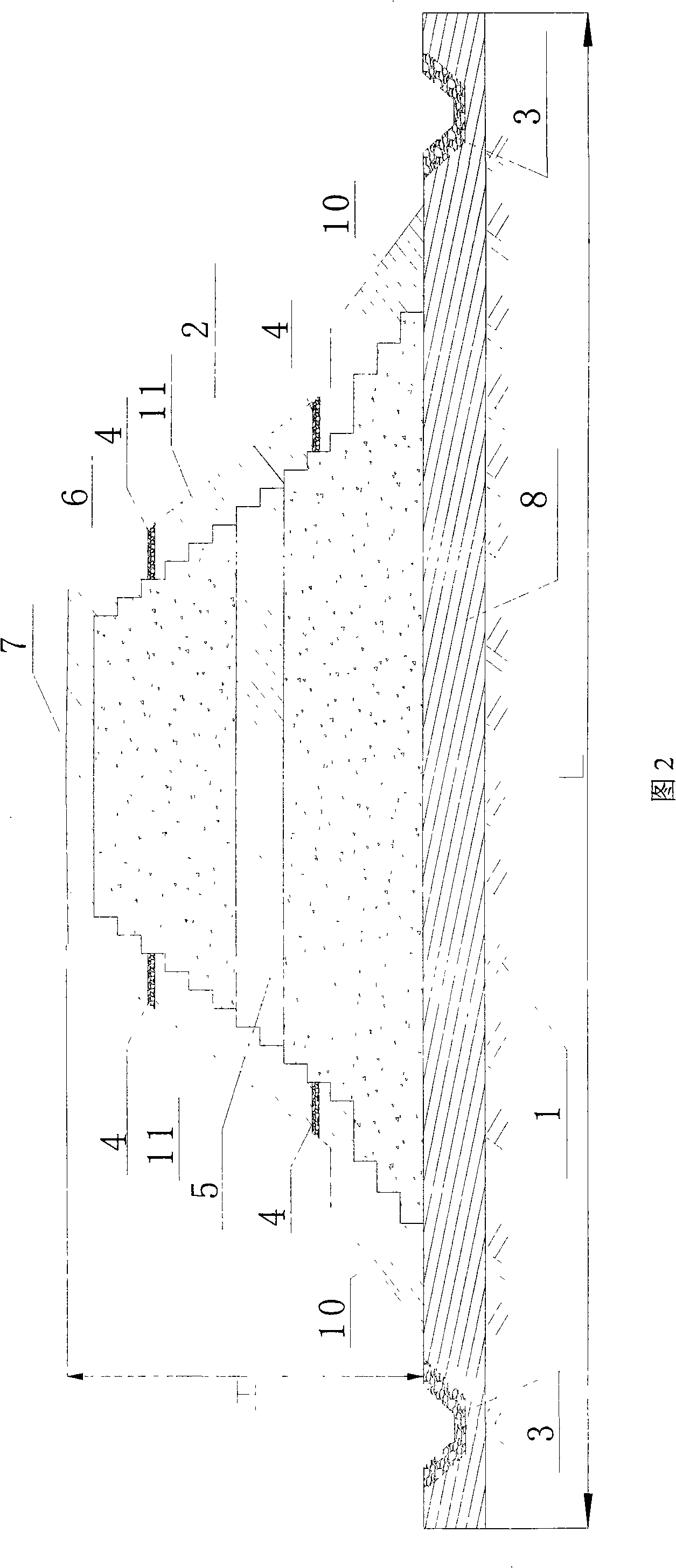

[0039] The present invention will be further described below in conjunction with accompanying drawing.

[0040] A method for filling road subgrades with steel scrap slag, the steps of which are:

[0041] a. Selection of steel slag for roadbed filling

[0042] Subgrade engineering has strict requirements on the quality of filling materials. Problems such as the expansion and pulverization of steel slag will endanger the safety of the subgrade. Therefore, various indicators of steel slag must be strictly controlled:

[0043] (1) New slag must not be used or mixed in, and scrap steel slag stored for more than one year should be used. The maximum particle size of the steel slag used for filling the roadbed should not be greater than 40mm (square hole), and the content of particles with a particle size greater than 20mm should not exceed 40%. The recommended grading range in Table 1 should be adopted. Coarse material concentration and overhead phenomenon shall not occur during f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Dry density | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com