TPU leather production method

A manufacturing method and release film technology, applied in textiles and papermaking, etc., can solve the problems of peeling off of the printed layer, no texture, rough surface of the cloth layer, etc., and achieve the effect of fine printing pattern and not easy to fall off.

Active Publication Date: 2011-01-05

李其树

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, both of these two methods have shortcomings. The first method is because the surface of the cloth layer is rough, and the printed pattern is not very fine and has no texture; the second method can print exquisite patterns, but because the printing layer is on the TPU leather The outermost layer, when in use, the printed layer is easy to fall off due to scratches or abrasion

Method used

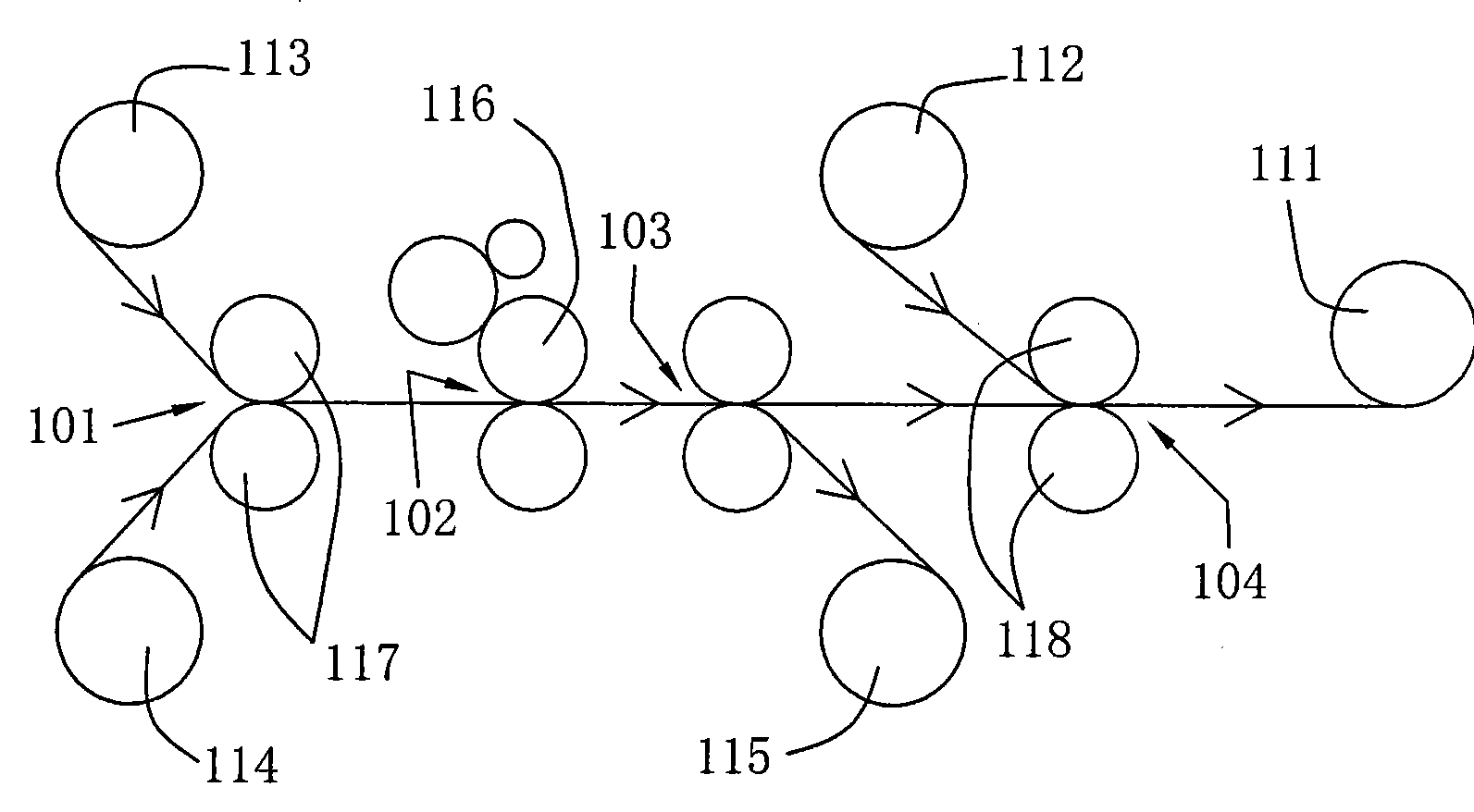

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

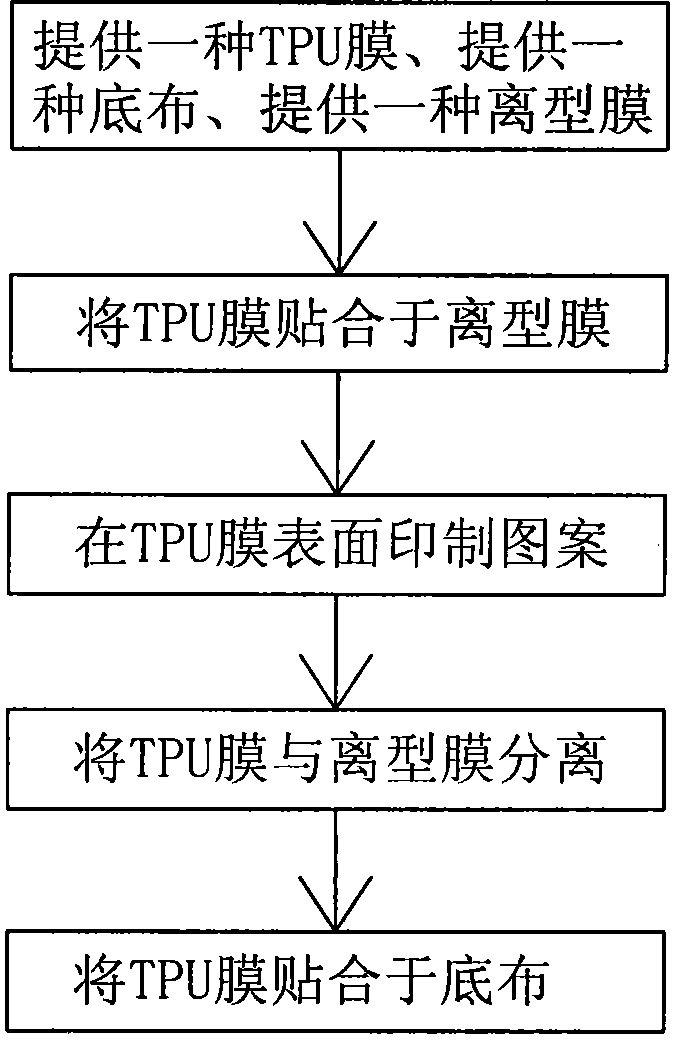

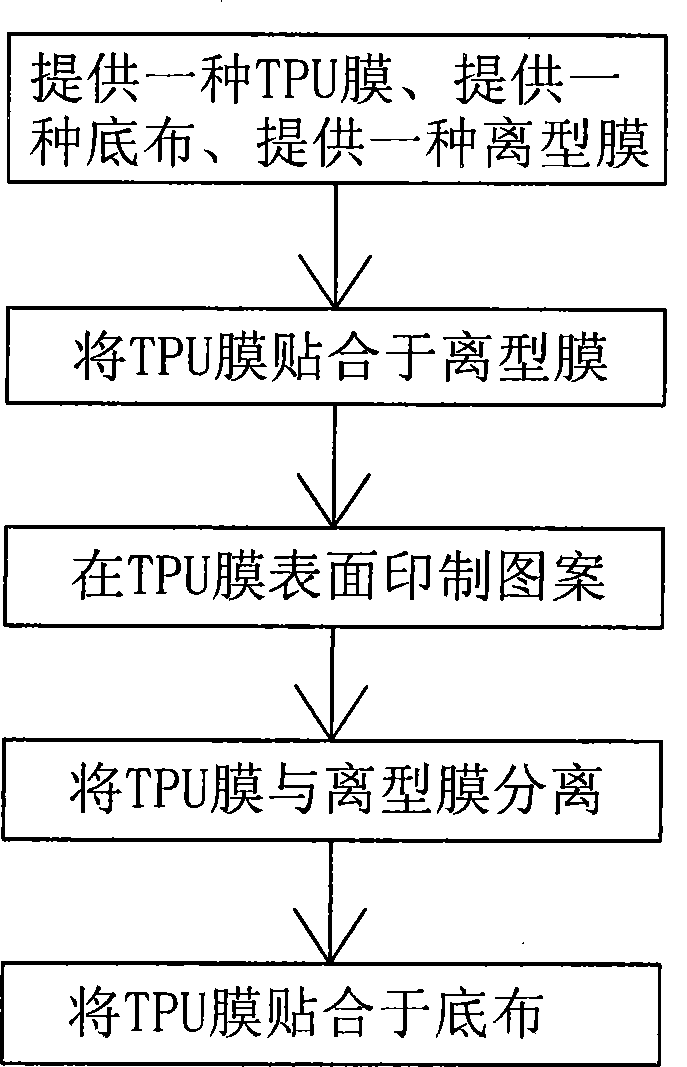

The invention relates to environment-friendly TPU leather, in particular to a manufacturing method for TPU leather with patterns. The invention is characterized in that the method comprises the following steps: firstly, a TPU mold, a base fabric and an off-mould membrane are offered; secondly, the TPU membrane is affixed to the off-mould membrane; thirdly, the patterns are printed on the surface of the TPU membrane; fourthly, the TPU membrane is separated from the off-mould membrane; and fifthly, the TPU membrane is affixed to the base fabric, with the surface printed with the patterns facingthe base fabric. The invention provides the manufacturing method for TPU leather with fine patterns which can not drop off easily.

Description

A kind of manufacture method of TPU leather technical field The invention relates to environment-friendly TPU leather, in particular to a method for manufacturing patterned TPU leather. Background technique Leather materials are widely used in modern industry and daily life, such as shielding clothing, fashion, bags, wallpaper, sofas, etc. Traditional leather materials are generally PVC leather coated or laminated with PVC on the cloth base. However, the PVC layer of PVC leather is non-degradable, and the extensive use of PVC leather results in a large amount of non-degradable industrial or domestic waste. PVC leather is gradually being eliminated because it is not conducive to environmental protection. TPU leather is a new type of leather material. Because TPU is degradable at room temperature, it meets environmental protection requirements. In addition, compared with PVC, TPU has waterproof function and good air permeability. Therefore, TPU is more durable than PVC. P...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06N3/14

Inventor 李其树

Owner 李其树

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com