Method for preparing metallic titanium with high temperature fused salt electrolysis of titanium dioxide

A technology of titanium dioxide and high-temperature molten salt, which is applied in the field of separation and extraction of metal materials, and can solve problems such as difficulties in industrial application, poor conductivity of titanium dioxide, and low current efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

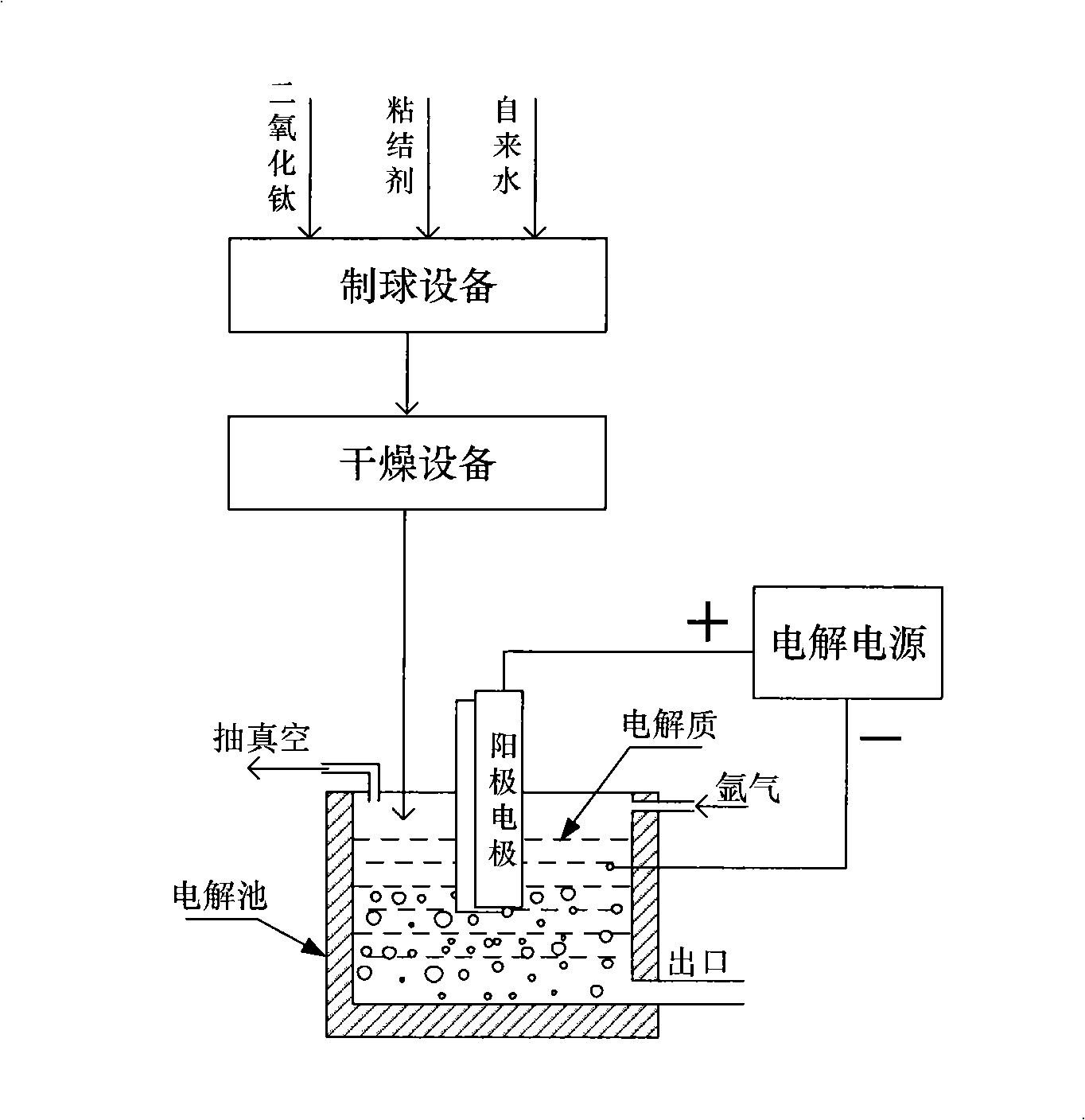

Image

Examples

Embodiment 1

[0057] The anode electrode is graphite.

[0058] Electrolyte is calcium fluoride CaF 2 .

[0059] The method for preparing metal titanium by molten salt electrolysis of titanium dioxide comprises the following steps:

[0060] The first step: making titanium dioxide spheres

[0061] (A) Titanium dioxide TiO 2 , PVC binder and tap water are added to the pelletizing equipment to produce pellets with a particle size of 60-120mm;

[0062] Dosage: 100g of titanium dioxide TiO 2 Add 8g of binder and 2g of tap water;

[0063] (B) drying the pellets with a particle size of 60 to 120 mm at a temperature of 300° C. for 20 minutes to obtain titanium dioxide spheres;

[0064] The second step: Molten salt electrolysis to produce titanium metal

[0065] (A) adding the titanium dioxide spheres prepared in the (B) step of the first step to the electrolytic cell;

[0066] (B) The electrolyte calcium fluoride CaF 2 Added to the electrolytic cell, the amount of electrolyte added is 2 / 3 o...

Embodiment 2

[0073] The anode electrode is graphite.

[0074] Electrolyte is calcium fluoride CaF 2 A mixed molten salt with lithium fluoride LiF, the content of lithium fluoride LiF in the mixed molten salt is 20% by weight.

[0075] A method for preparing metallic titanium by high-temperature molten salt electrolysis of titanium dioxide comprises the following steps:

[0076] The first step: making titanium dioxide spheres

[0077] (A) Titanium dioxide TiO 2 , Carboxymethyl cellulose calcium binder and tap water are added to the pelletizing equipment to obtain pellets with a particle size of 60-120mm;

[0078] Dosage: 100g of titanium dioxide TiO 2 Add 8g of binder and 3g of tap water;

[0079] (B) drying the pellets with a particle size of 60 to 120 mm at a temperature of 200° C. for 30 minutes to obtain titanium dioxide spheres;

[0080] The second step: Molten salt electrolysis to produce titanium metal

[0081] (A) adding the titanium dioxide spheres prepared in the (B) step o...

Embodiment 3

[0089] The anode electrode is graphite.

[0090] Electrolyte is calcium fluoride CaF 2 A mixed molten salt with lithium fluoride LiF, the weight percent content of lithium fluoride LiF in the mixed molten salt is 5.

[0091] A method for preparing metallic titanium by high-temperature molten salt electrolysis of titanium dioxide comprises the following steps:

[0092] The first step: making titanium dioxide spheres

[0093] (A) Titanium dioxide TiO 2 , PVC binder and tap water are added to the pelletizing equipment to produce pellets with a particle size of 60-120mm;

[0094] Dosage: 100g of titanium dioxide TiO 2 Add 5g of binder and 5g of tap water;

[0095] (B) drying the pellets with a particle size of 60 to 120 mm at a temperature of 150° C. for 60 minutes to obtain titanium dioxide spheres;

[0096] The second step: Molten salt electrolysis to produce titanium metal

[0097] (A) adding the titanium dioxide spheres prepared in the (B) step of the first step to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com