Control method for b value of sodium aluminate solution

A control method, sodium aluminate technology, applied in the direction of preparation of alkali metal aluminate/alumina/aluminum hydroxide, etc., can solve problems such as not being found, reduce b value, reduce b value of sodium aluminate solution, The effect of convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

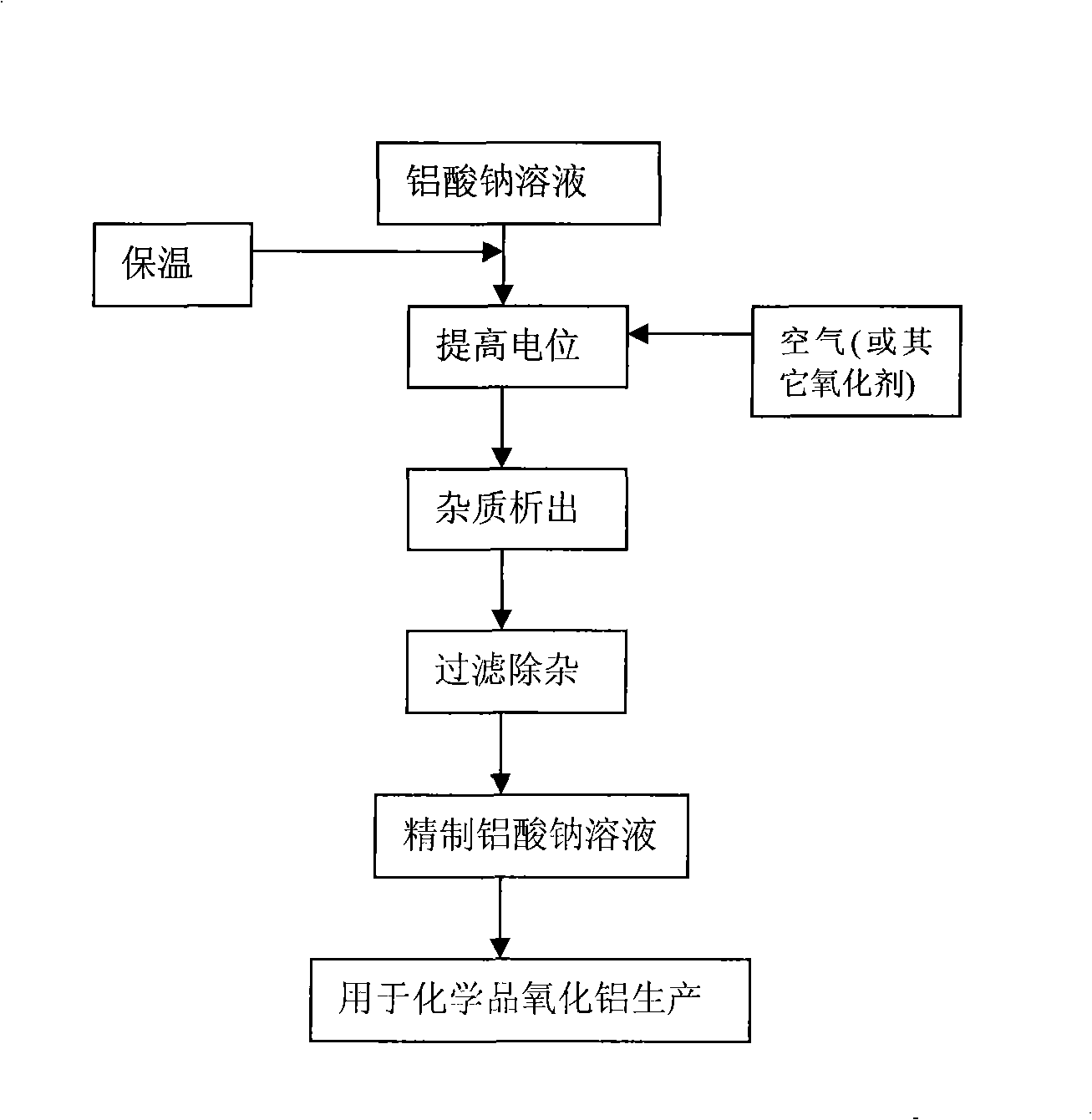

Image

Examples

Embodiment 1

[0012] The b-value control method of the sodium aluminate solution described in the present invention is to reduce the b-value of the solution by increasing the solution potential, take the sodium aluminate semen in the sintered alumina production process, raise the temperature to 85°C, keep the constant temperature, and pour into it Introduce air at a rate of 15L / min L for 15 minutes to make the potential of the solution reach 0.9V and make the Fe in the solution 2+ Oxidized to Fe 3+ And removed.

[0013] Some iron ions in the sodium aluminate solution are removed, the b value of the filtered sodium aluminate solution is reduced, and the sodium aluminate semen that meets the requirements for the production of chemical alumina (such as agate filler) is obtained. The test results are shown in Table 1.

Embodiment 2

[0015] The b-value control method of the sodium aluminate solution described in the present invention is to reduce the b-value of the solution by increasing the solution potential, take the sodium aluminate semen in the sintered alumina production process, raise the temperature to 90°C, keep the constant temperature, and inject Introduce air at a rate of 40L / min L for 20 minutes to make the potential of the solution reach 1.2V and make the Fe in the solution 2+ Oxidized to Fe 3+ And removed, the filtered sodium aluminate solution b value is reduced. The test results are shown in Table 1.

Embodiment 3

[0017] The b-value control method of the sodium aluminate solution described in the present invention is to reduce the b-value of the solution by increasing the solution potential, take the sodium aluminate semen in the sintered alumina production process, raise the temperature to 80°C, keep a constant temperature, and inject Introduce air at a rate of 30L / min·L for 15 minutes to make the potential of the solution reach 1.1V and make the Fe in the solution 2+ Oxidized to Fe 3+ And removed, the filtered sodium aluminate solution b value is reduced. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com