Modularized railway signal mechanical room and case body structure

A technology of railway signal and box structure, which is applied in the fields of railway signal, railway signal and safety, railway car body parts, etc. It can solve the problems of delay in on-site house construction, long house construction period, large amount of on-site construction and labor intensity, etc. Achieve the effects of shortening the railway construction period, reducing professional interface coordination, and reducing design workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

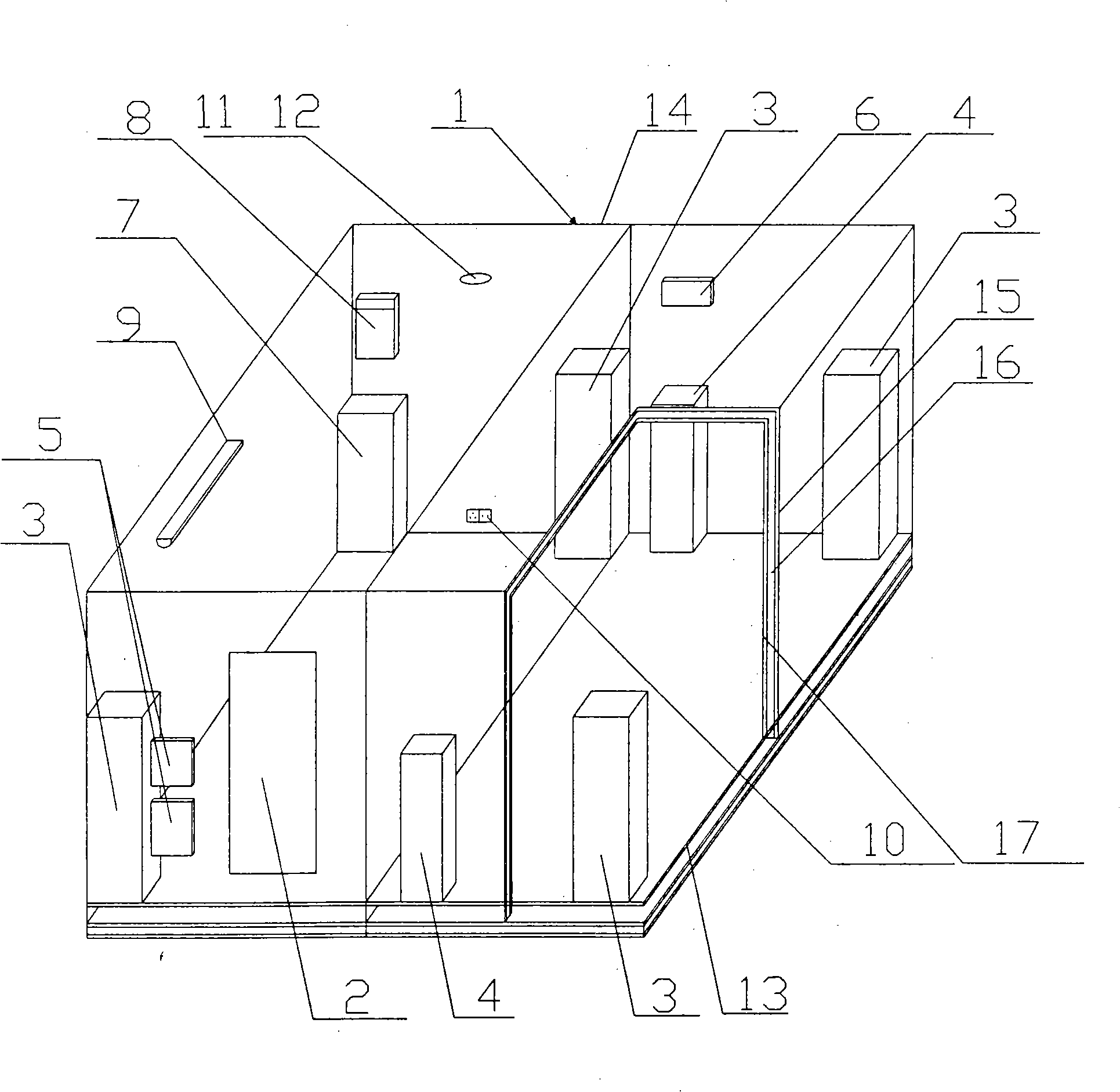

[0045] The modularized railway signal machine room and its box structure of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0046] Such as figure 1 As shown, the modularized railway signal machine room of the present invention includes a box body 1 and a door 2 formed on one side of the box body 1, and the box body 1 is composed of one or more boxes that can be transported separately and on site. The assembled box body basic unit 14 is formed. Described box body 1 is provided with general air conditioner 3, lightning protection cabinet 7, distribution box 8, lighting device 9, socket 10 and fire-fighting equipment, and described fire-fighting equipment includes fire-fighting cabinet 4, fire-fighting control system 5 , Fire pressure relief valve 6; There is also space for setting 6-12 special equipment cabinets in the box body 1, such as computer interlocking cabinets, train control center cabinets, frequ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com