Processing method for homogeneous and natural texture-forming bamboo plywood

A technology of bamboo plywood and processing method, which is applied to other plywood/plywood appliances, wood processing appliances, sugarcane machining and other directions, can solve the problems affecting the uniformity and production efficiency of blank density, high strength of bamboo plywood, and disorderly arrangement of inner membrane and other problems, to achieve the effect of equal thickness, uniform texture, and natural appearance and color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

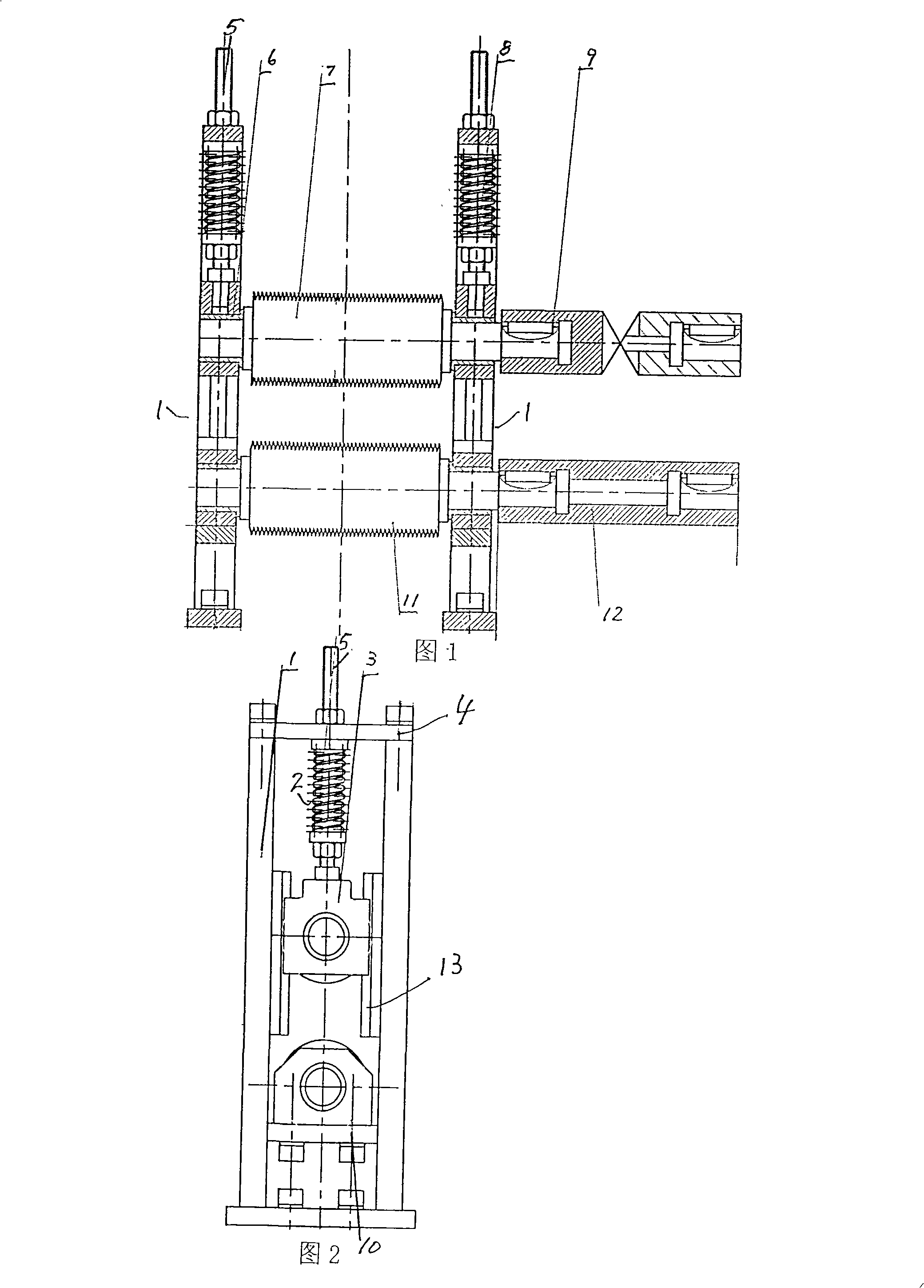

Image

Examples

Embodiment Construction

[0020] Saw the bamboo into several sections, divide each section into bamboo slices with a slicing machine, remove green and yellow from the bamboo slices, split each bamboo slice into several bamboo strips, and press a part of the bamboo strips into bamboo shreds on a wire pressing machine. Put the bamboo shreds into the carbonization tank, add steam, adjust the pressure to 0.2 or 0.4 or 0.6MPa, and keep it at 130°C or 140°C or 150°C for 1 hour or 2 hours or 4 hours or 5 hours.

[0021] The bamboo shreds and bamboo strips are woven into parallel bamboo curtains with threads, and the thickness of the panels used in the same bamboo curtain is basically the same.

[0022] Bamboo curtains are dried-dipping-drying for the second time, and stacked layer by layer on the hot press board to form blanks, and the groups of adjacent two layers of bamboo curtains form an angle of 90°. The surface layer consists of 1 or 2 layers or 3 layers or 4 layers of bamboo screens made of bamboo fila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com