On-machine quality detecting system for complex space type surface

A detection system and space technology, applied in the direction of mechanical measuring device, general control system, control/regulation system, etc., to achieve the effect of low time cost, ensure processing accuracy, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing, the implementation of the present invention is described as follows:

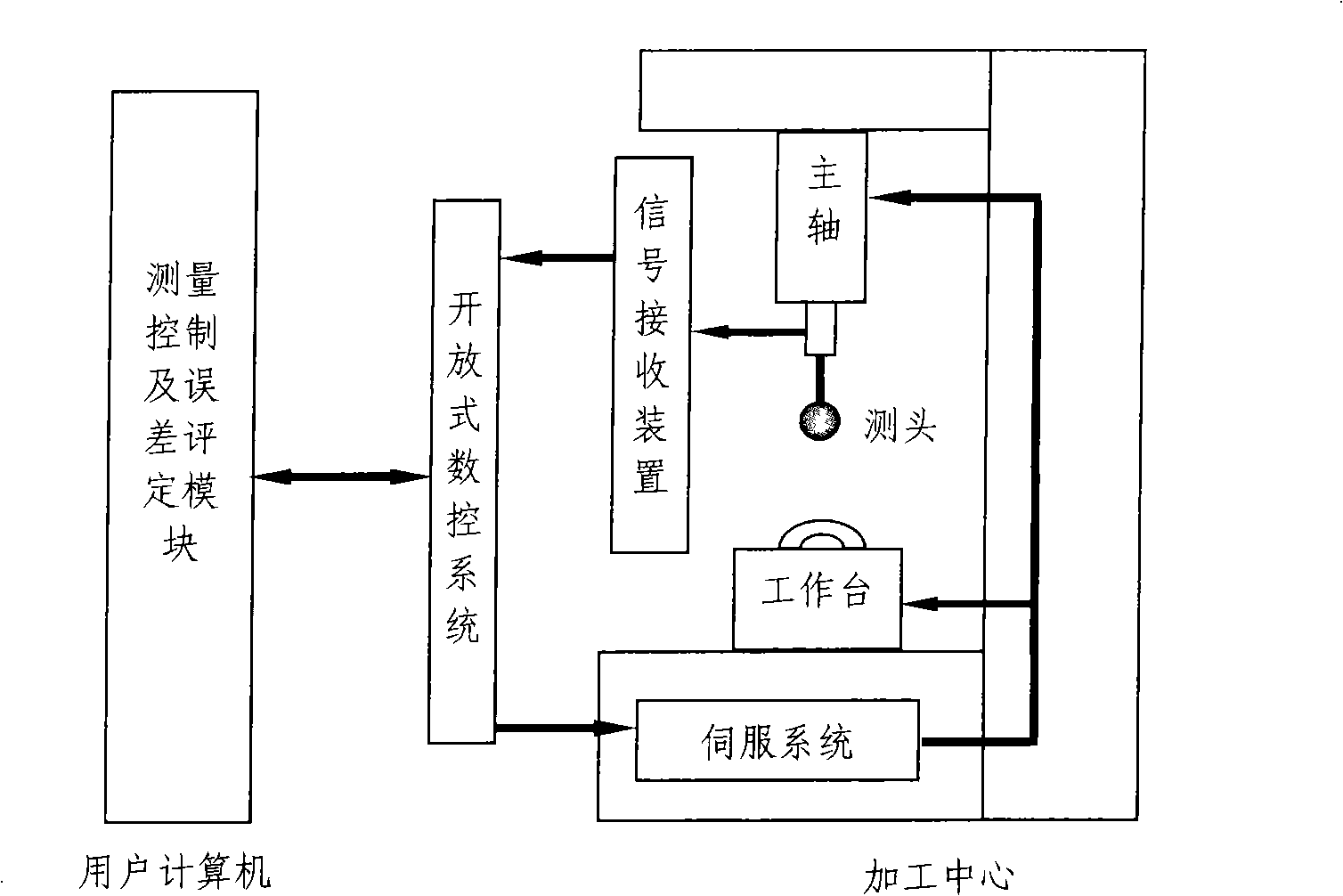

[0023] exist figure 1 In , the tactile three-coordinate measuring probe is mounted on the machine tool spindle through a standard taper shank. The connection between the two is very simple, but attention should be paid to the alignment of the measuring head and the axis of the spindle. The main function of the probe is to collect points on the surface of the workpiece. When the measuring end of the probe touches the surface of the workpiece, a trigger signal is sent and transmitted to the signal receiving device. The signal receiving device is installed at an appropriate position of the machining center to receive the trigger signal from the measuring head, and after necessary signal conditioning, transmit the signal to the numerical control system of the machining center. The measuring head is a sensor. Since the signal transmission between the probe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com