Film bearing seal device

A sealing device and oil film bearing technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of seal failure, poor anti-axial and radial runout effects, and few contact parts, and achieve extended use. Longevity, increased penetration resistance, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

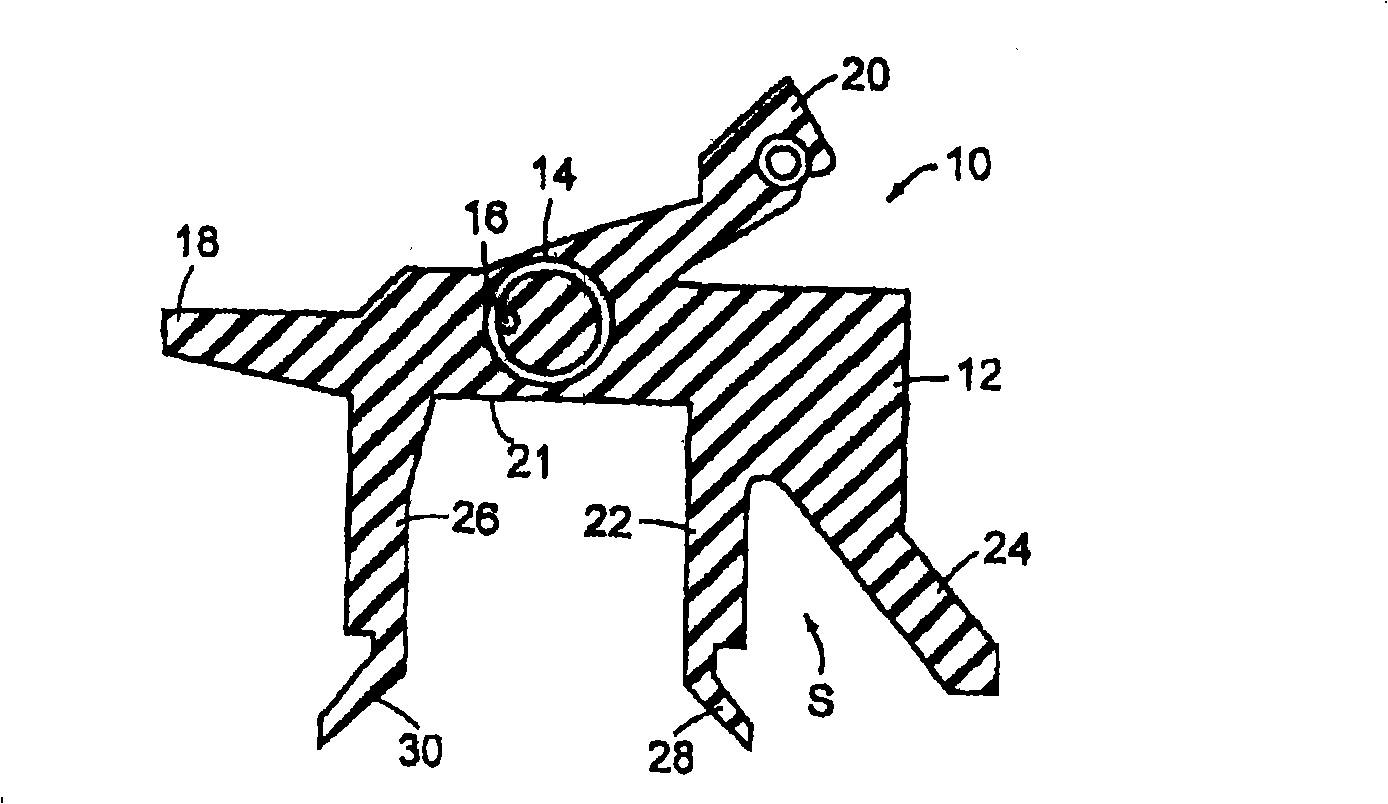

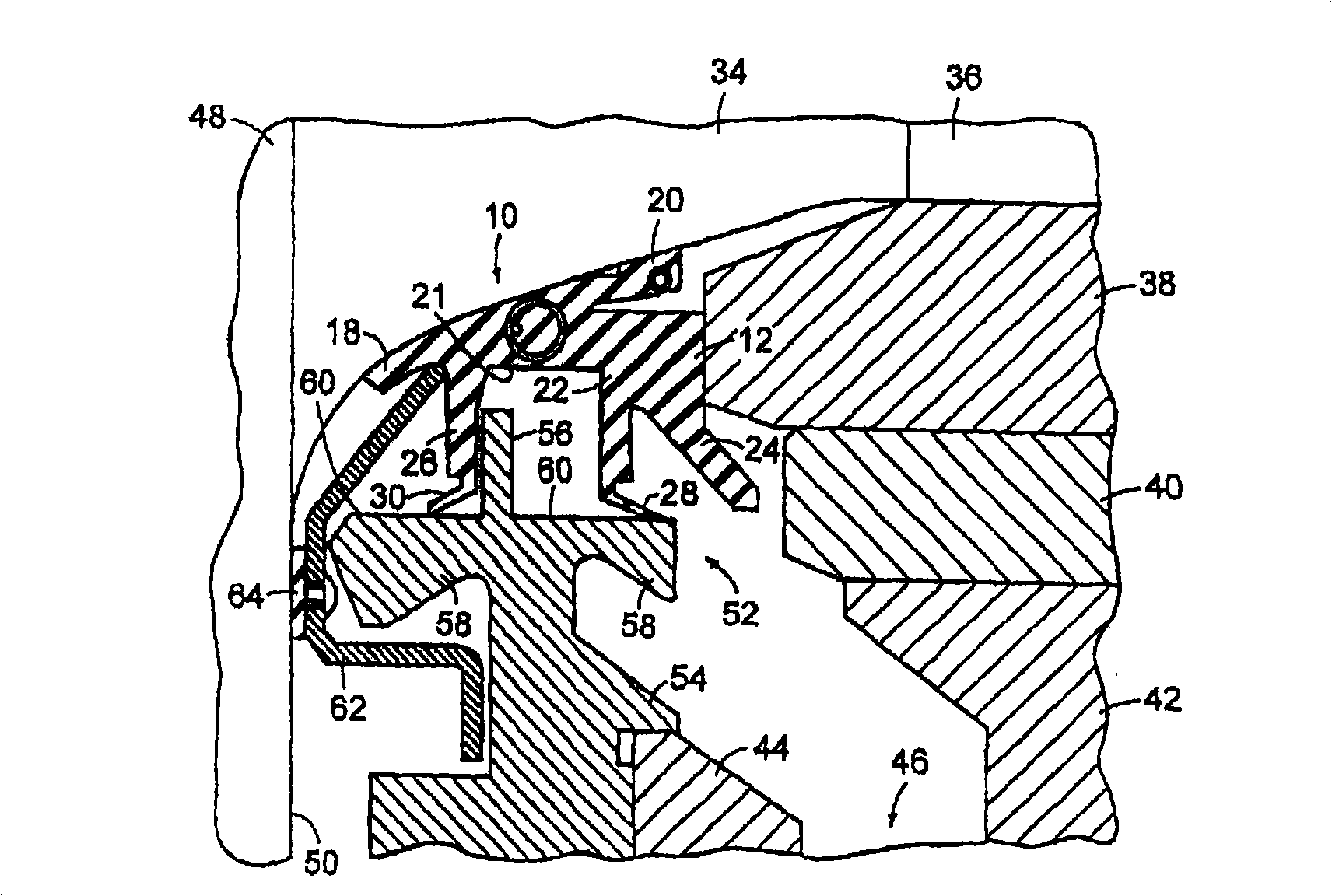

[0032] Figure 3- Figure 7 As shown, the main structure of the present invention includes a neck seal A and a rigid annular sealing end plate F fixed on the bearing seat E, and the neck seal A includes an annular seal body 1 with a slot 7 and inserted into the slot The sealing part B on 7, the coil spring 6 and the wire rope 4 are embedded in the annular sealing body 1, the slot 7 is opposite to the sealing surface 41 of the rigid annular sealing end plate, and the rigid annular sealing end opposite to the sealing surface 41 A protective water seal D is provided on the board F. The sealing part B includes a base 19 inserted into the slot 7, a water sealing limb 17 and an oil sealing limb 25 perpendicular to the base, and the water sealing limb 17 and the oil sealing limb 25 are connected with mutually diverging water sealing lips 15 And the sealing lip 23, the sealing part B inserted into the slot is placed between the rigid annular sealing end plate F and the annular sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com