Processing process for ketene dimer rectification residue

A technology of ketene essence and residue, which is applied in the field of diketene distillation residue treatment process, can solve the problems of waste of resources, high risk factor, inability to effectively recover acetone, etc., and achieve the effect of avoiding pollution and high social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

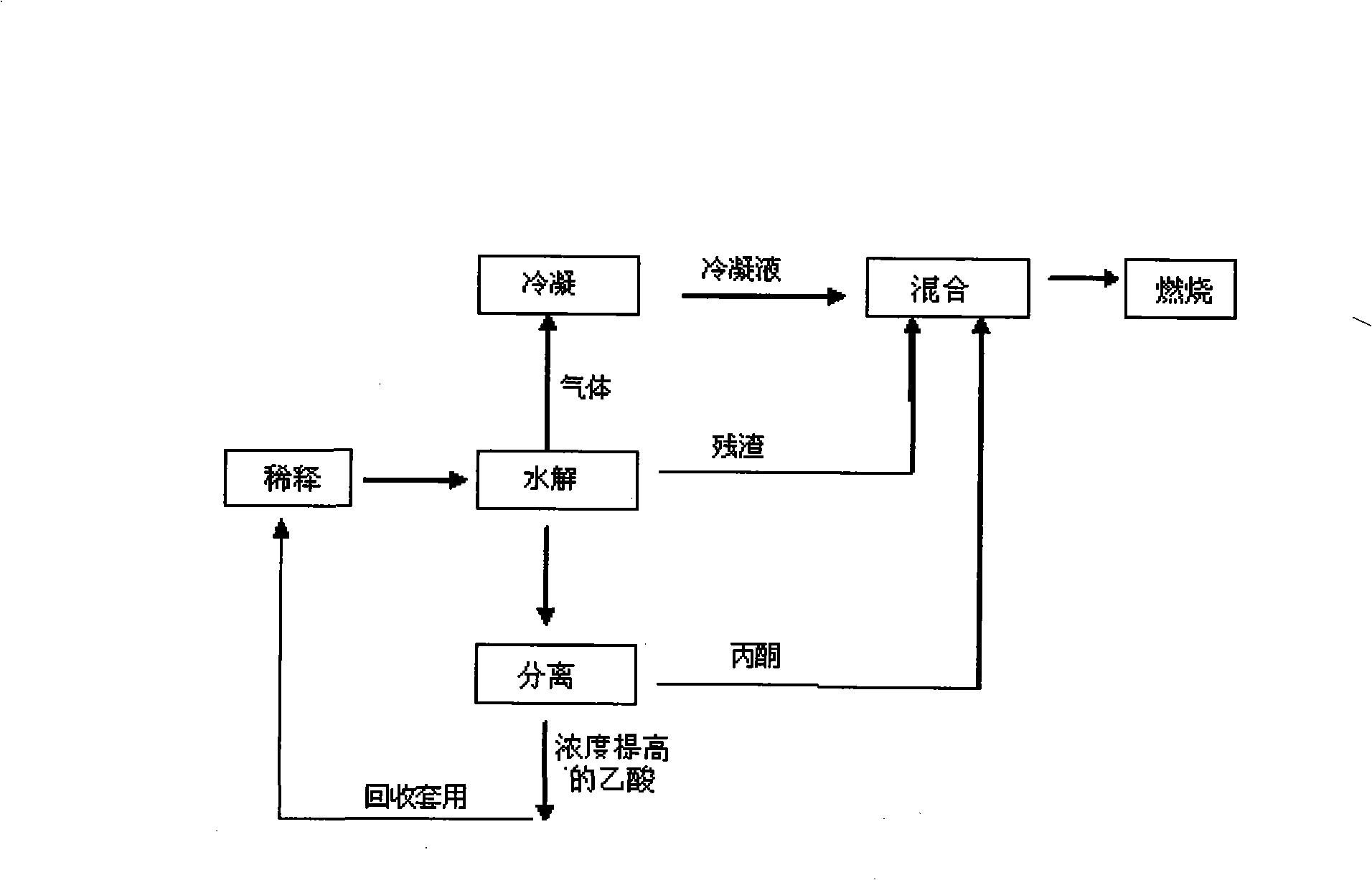

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of this invention will be described in detail below in conjunction with embodiment:

[0015] (1), hydrolysis: add 40% acetic acid 600kg in 2000L reaction kettle, hydrolysis temperature is 95 ℃, dropwise add 1200kg diketene rectification residue, stir, make mixing evenly, after dropwise addition, heat insulation with jacket for 1 hour, Obtain 1200kg of 65% acetic acid solution containing about 20% acetone content. A cyclone-type tube condenser was installed on the reaction kettle, and the temperature was lowered with -15°C brine, and the tail gas discharged from the reaction kettle was condensed into a condensate to obtain acetone with a purity of 95%.

[0016] (2), separation: the above-mentioned hydrolyzate is placed in the continuous distillation tower, maintains tower top temperature 55-57 ℃, separates acetone, until there is no obvious discharge, obtains about 100kg of acetone more than 95%.

[0017] (3), mixing, the acetone obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com