Multilayer, multi-frequency, multi-amplitude vibration-net grading sieve

A grading sieve and multi-frequency technology, applied in the direction of sieving, solid separation, grid, etc., can solve the problems that are not conducive to screening and not conducive to improving screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

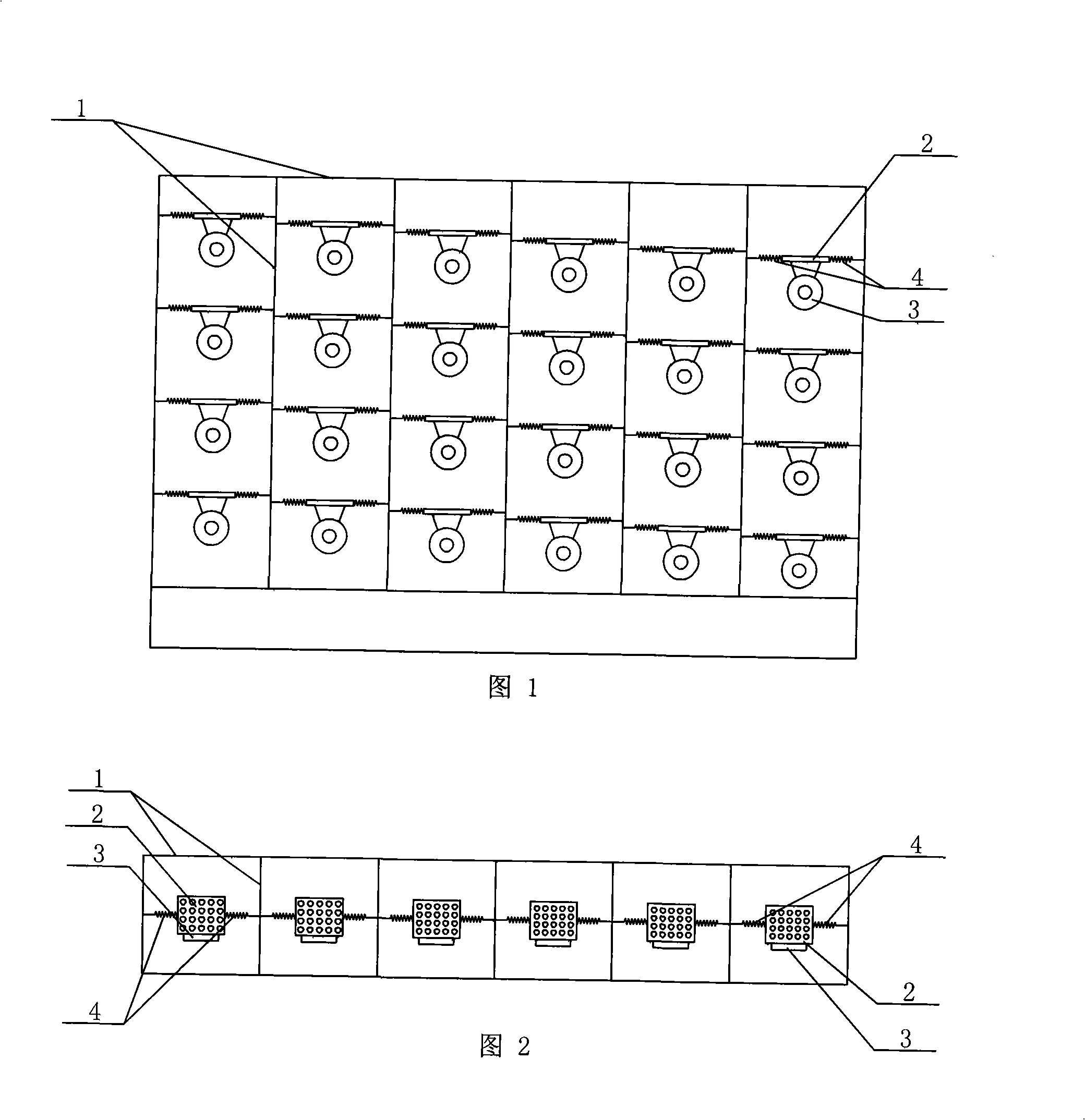

[0006] Referring to Figs. 1 and 2, this specific embodiment adopts the following technical scheme: it is composed of a vibrating screen bracket 1, a plurality of screens 2, a plurality of vibrating devices 3, and a plurality of connecting springs 4, and several screens 2 form a screen Layers, several screens 2 are lowered in turn, each screen 2 is connected with a connecting spring 4 on both sides, and the other end of the connecting spring 4 is fixed on the vibrating screen bracket 1, and each screen 2 is respectively provided with a vibrating device 3. In this specific embodiment, the vibration frequency and amplitude of each layer of vibrating screen meshes are different, and the screen openings become smaller from top to bottom, the frequency increases sequentially, and the amplitude decreases sequentially. This setting can adapt to materials of different particle sizes, improves screening efficiency and reduces screen clogging. This specific embodiment has the functions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com