Surface-mounted contraposition apparatus and method thereof

A surface mount and alignment device technology, applied in the direction of electrical components, electrical components, etc., can solve problems such as manpower and time, alignment errors, and affecting the quality of surface mounting of electronic components, so as to improve efficiency and improve The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The surface mount alignment device and its alignment method provided by the technical solution will be further described below in conjunction with the accompanying drawings and embodiments.

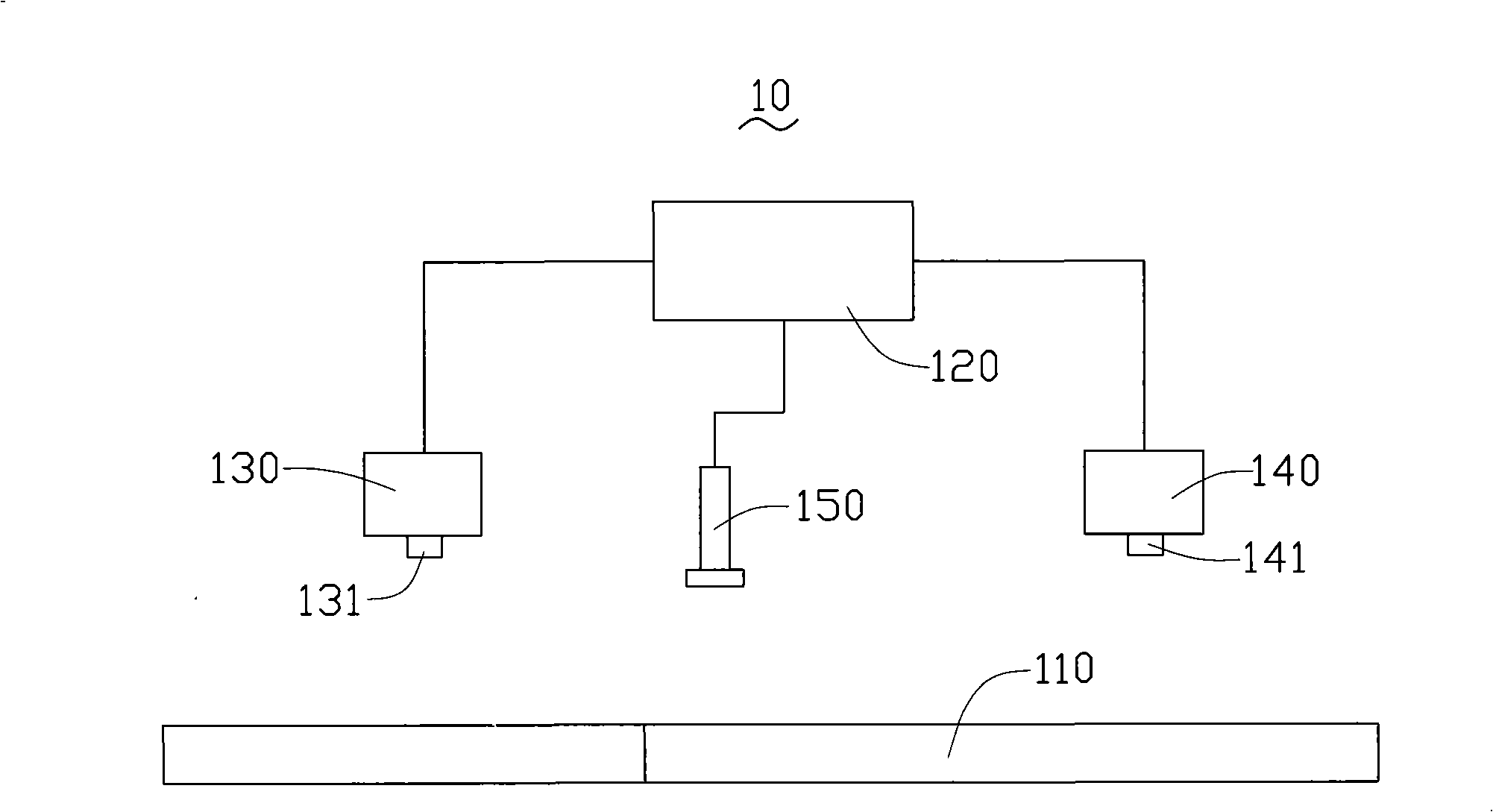

[0016] see figure 1 , the first surface mount alignment device 10 provided by the embodiment of the technical solution. The surface mount alignment device 100 includes a workbench 110 , a central control processing device 120 , a first image sensing device 130 , a second image sensing device 140 and a pick-and-place device 150 .

[0017] The workbench 110 is used for placing objects to be sensed, such as electronic components and printed circuit boards to be mounted. The worktable 110 is set opposite to the first image sensing device 130, the second image sensing device 140 and the pick-and-place device 150, so that the first image sensing device 130 and the second image sensing device 140 can be viewed from the workbench 110. above the workbench 110 to perform image sensing on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com