Sewing machine upper thread breaking and clamping device

A clamping device and sewing machine technology, applied in the direction of thread cutting mechanism, sewing machine components, sewing machine ferrule mechanism in sewing machines, etc., can solve the problems that it is difficult to play the function of the thread breaking mechanism normally, and the sewing thread breaking operation cannot be properly performed. , to achieve the effect of improving the efficiency of disconnection operations, preventing winding, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The preferred embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

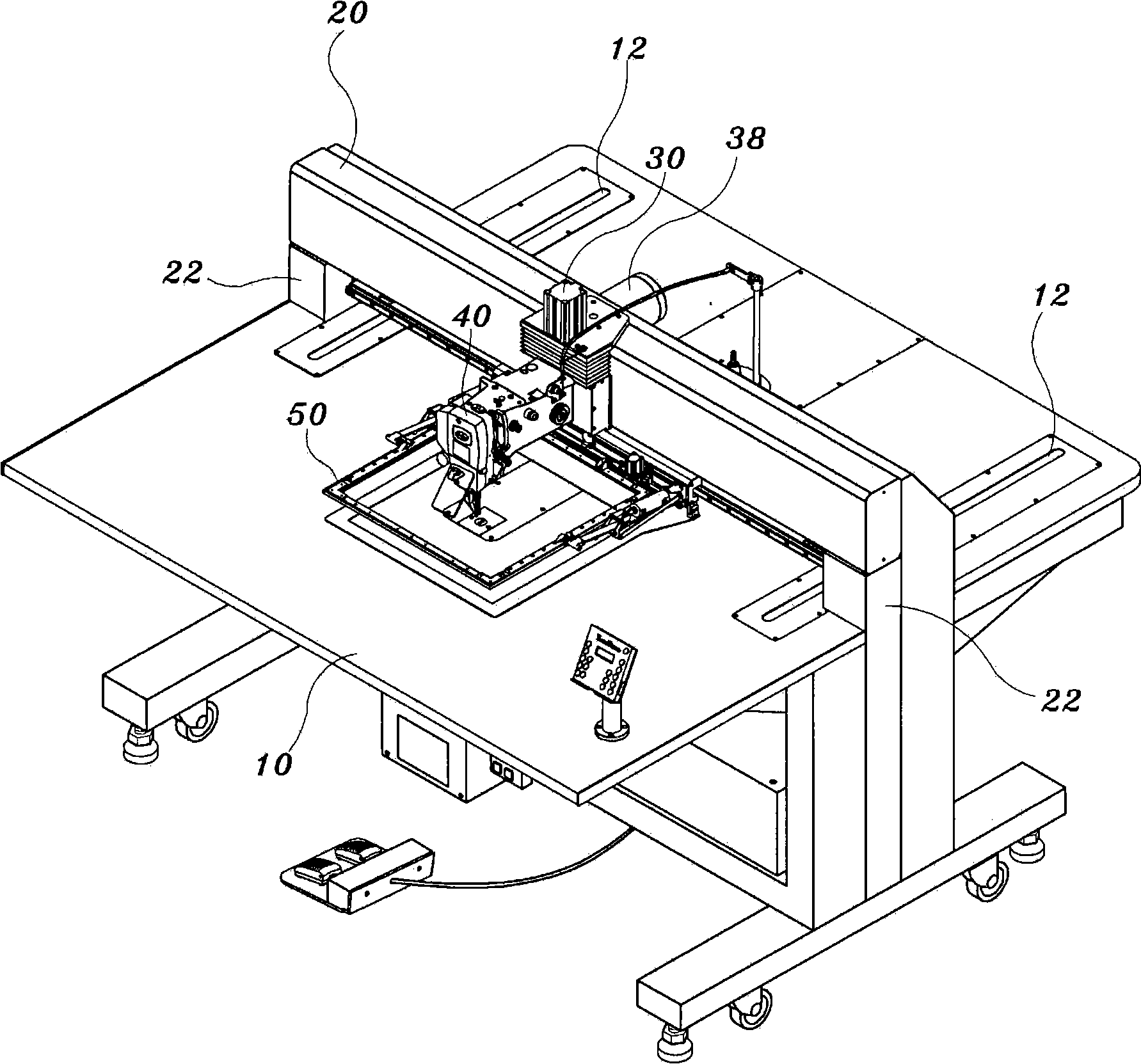

[0047] figure 1 It is a perspective view of a sewing machine equipped with an upper thread breaking and clamping device according to an embodiment of the present invention. On both sides of the workbench 10 where the object to be sewn is placed, support columns 22 are vertically erected, and a fixed frame 20 made of rectangular steel pipes is disposed between the above-mentioned support columns 22 along the horizontal direction.

[0048] There are elliptical guide holes 12 on both sides of the upper surface of the above-mentioned workbench 10, and the above-mentioned guide holes 12 can transmit the action of the Y-axis (the front and back direction of the sewing machine) transfer mechanism (not shown) below the workbench 10 to The sewn object fixing part 50 on the upper side of the workbench 10 .

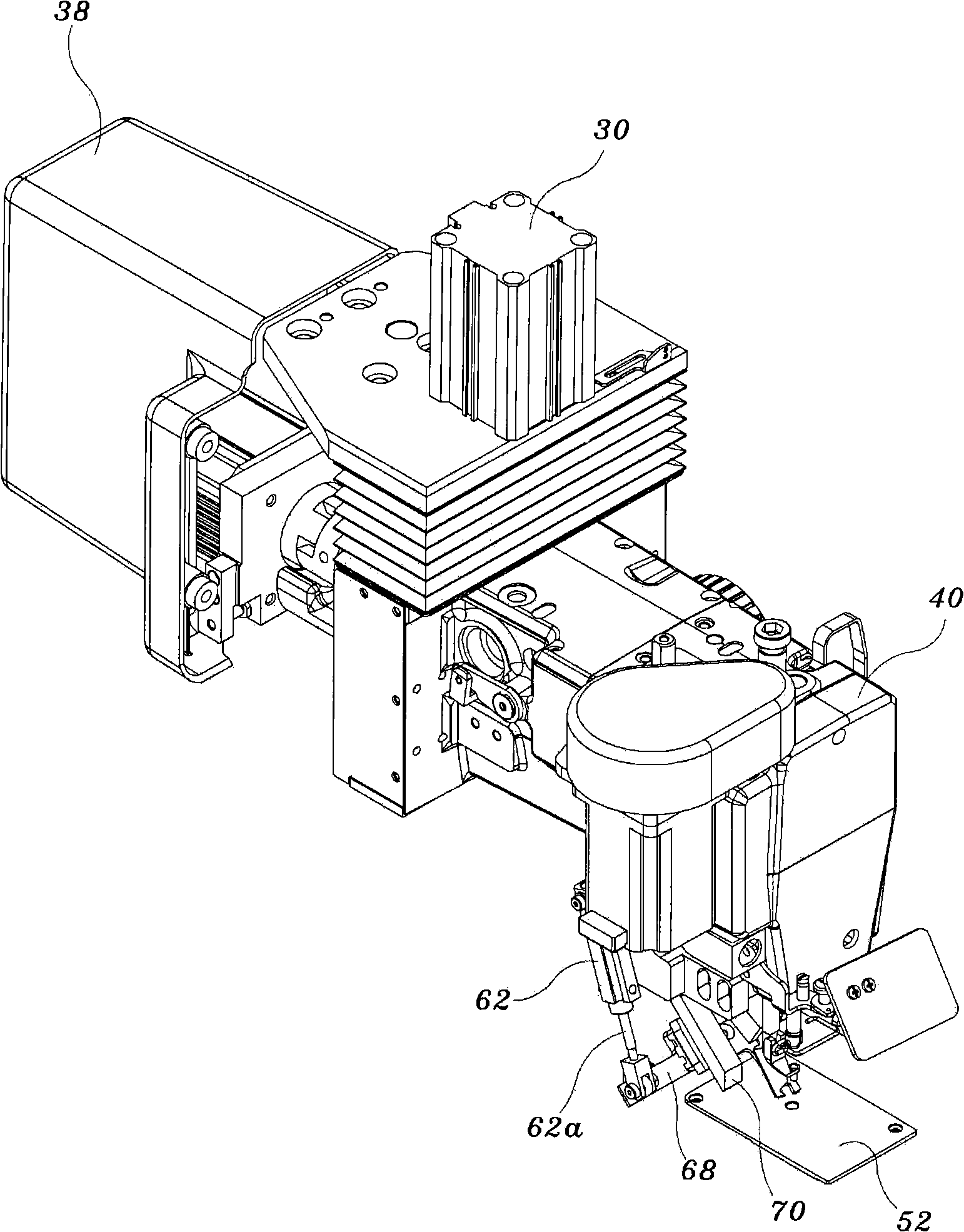

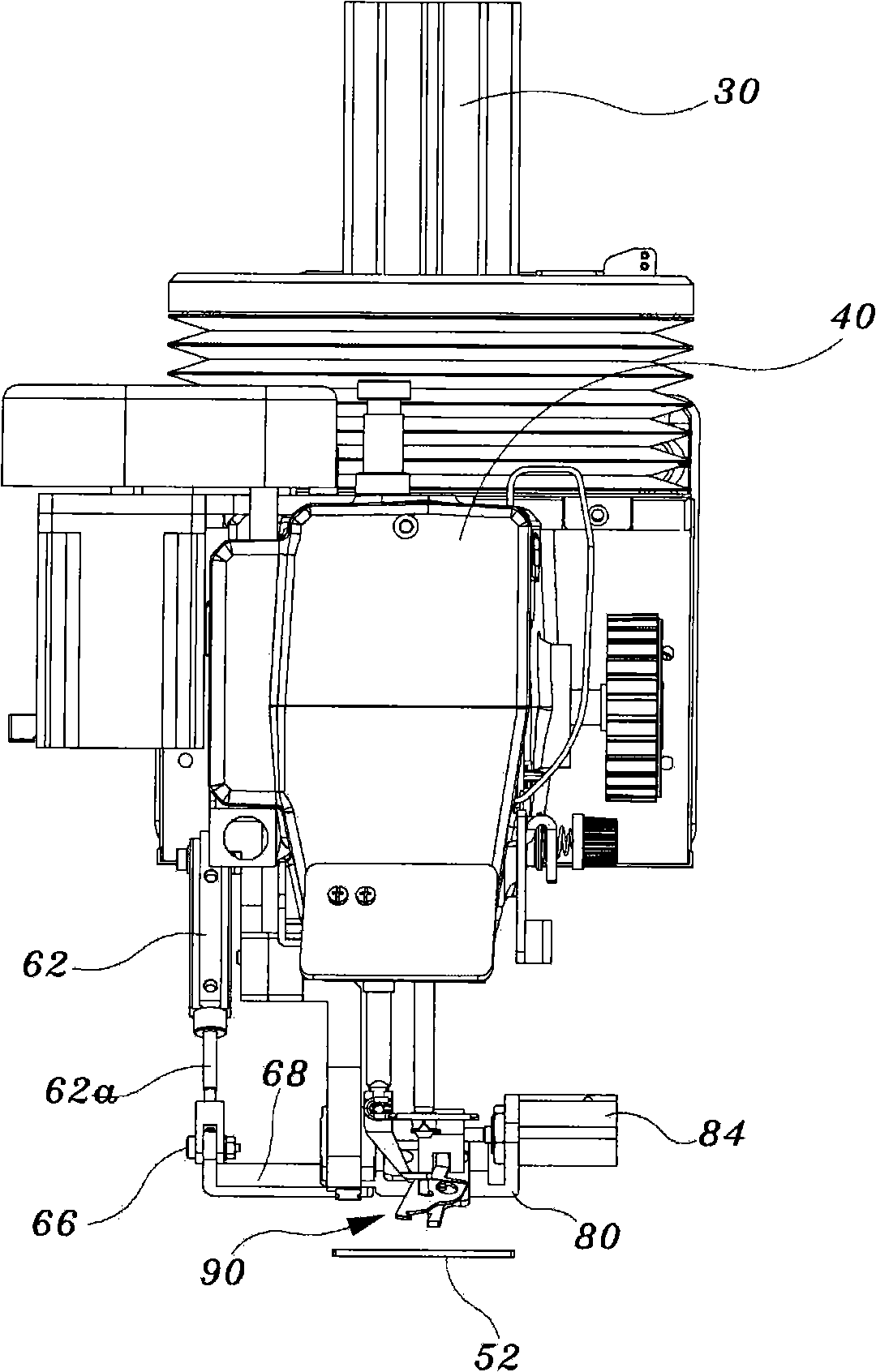

[0049] The sewing head 40 is combined w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com