Filter bag for vacuum cleaner and production method thereof

A technology for vacuum cleaners and filter bags, which is applied in the field of filter bags, and can solve problems such as cost-intensive, difficult bonding or welding of holding plates, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

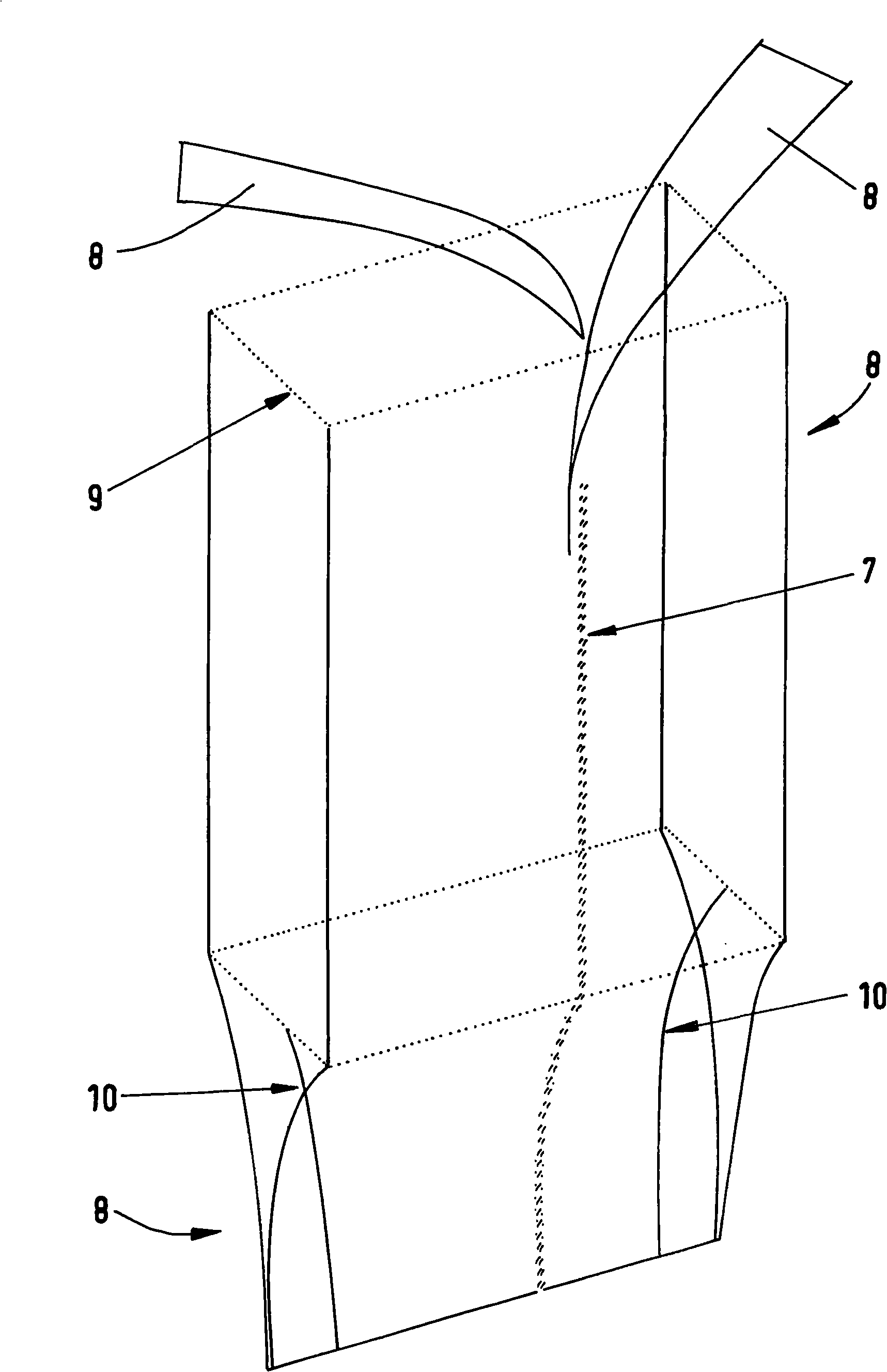

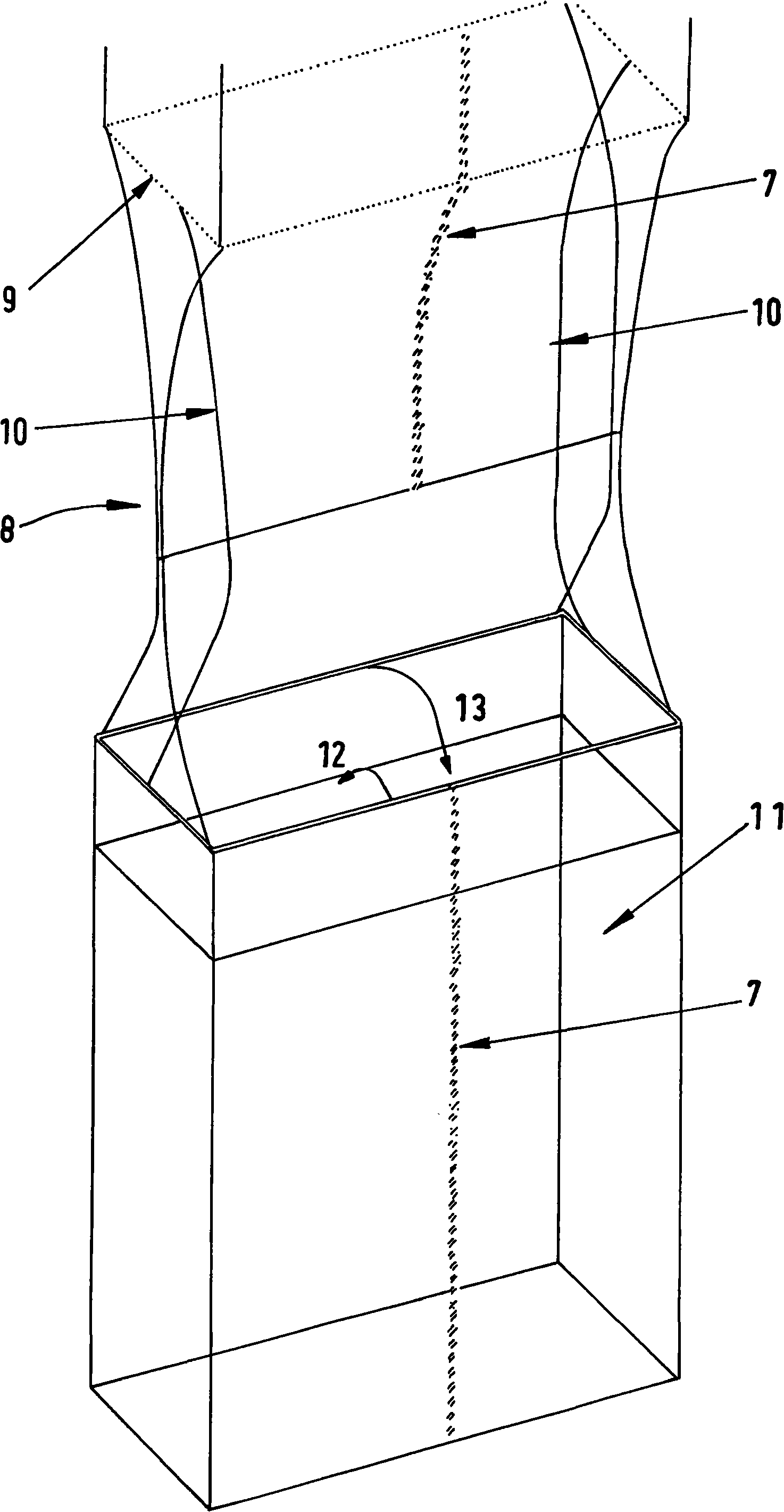

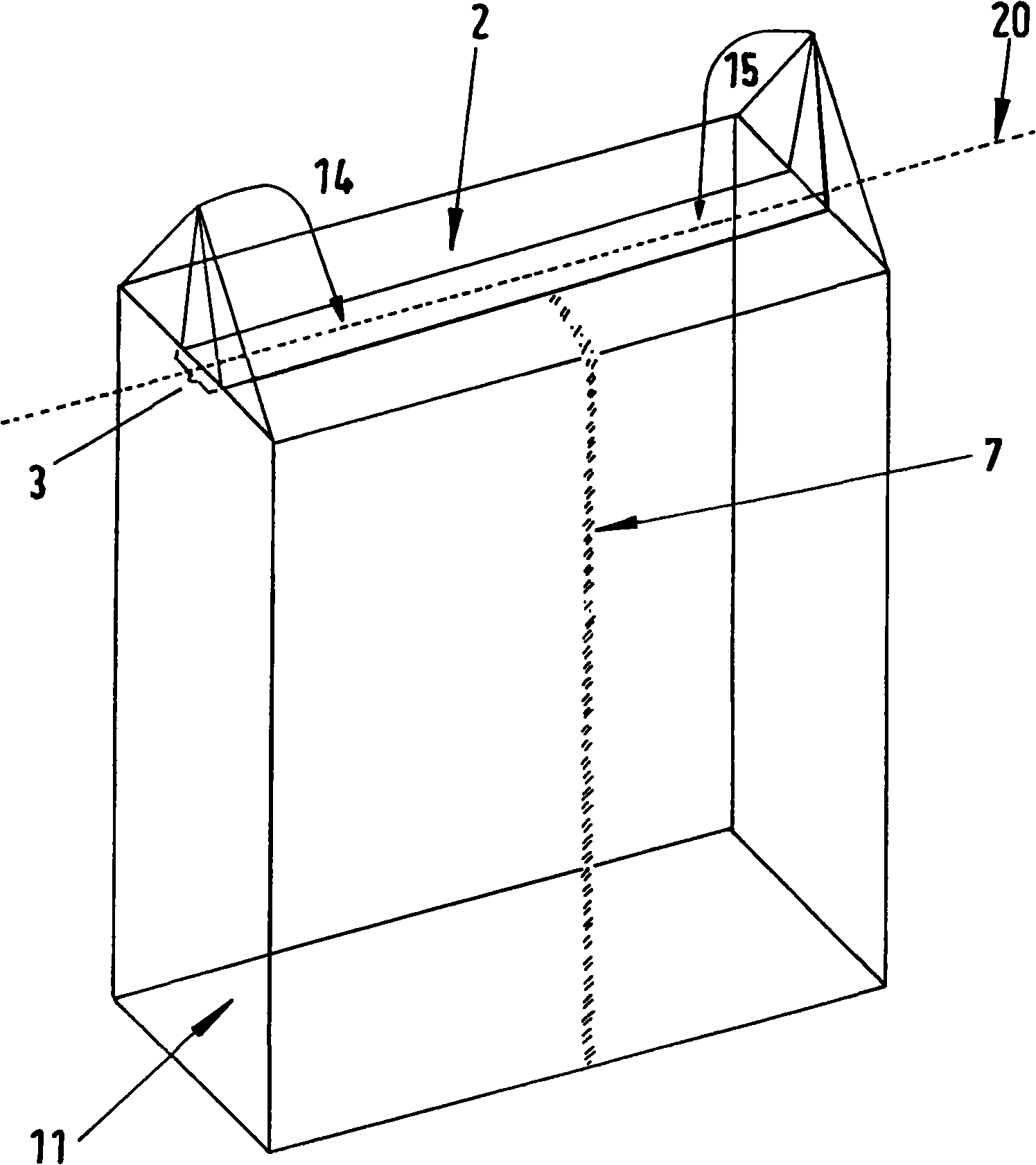

[0032] The sequence of figures 1 to 6 shows the individual steps for producing the filter bag according to the invention according to a first embodiment.

[0033] thus figure 1 A first method step for forming the tube is shown, in which the outer cover 8 is folded over a template 9 defining the shape of the filter bag and the weld seam 7 is then applied in order to form the tube. For example according to figure 1 , the template 9 is formed in the shape of a rectangular box, so that the bottom of the filter bag to be manufactured has a rectangular shape roughly corresponding to the rectangular shape predetermined by the template 9, as shown in the other sequence of figures below. An advantage of the method according to the invention and of the filter bags produced by this method is that, by predetermining the template 9 , filter bags of any shape can be produced with respect to the bottom. for figure 1 The outer covering 8 used in the embodiment shown is a multilayer nonw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com