Anode bleed control strategy for improved water management and hydrogen utilization

一种阳极气体、阳极的技术,应用在用于改善水管理和氢气利用的阳极排气控制策略领域,能够解决高电压下降速率、碳腐蚀、低氢气利用等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following description of the embodiments of the present invention intended for a control strategy for ending anode exhaust in a fuel cell structure with anode flow switching is merely exemplary in nature, and is not meant to limit the present invention or its application or use.

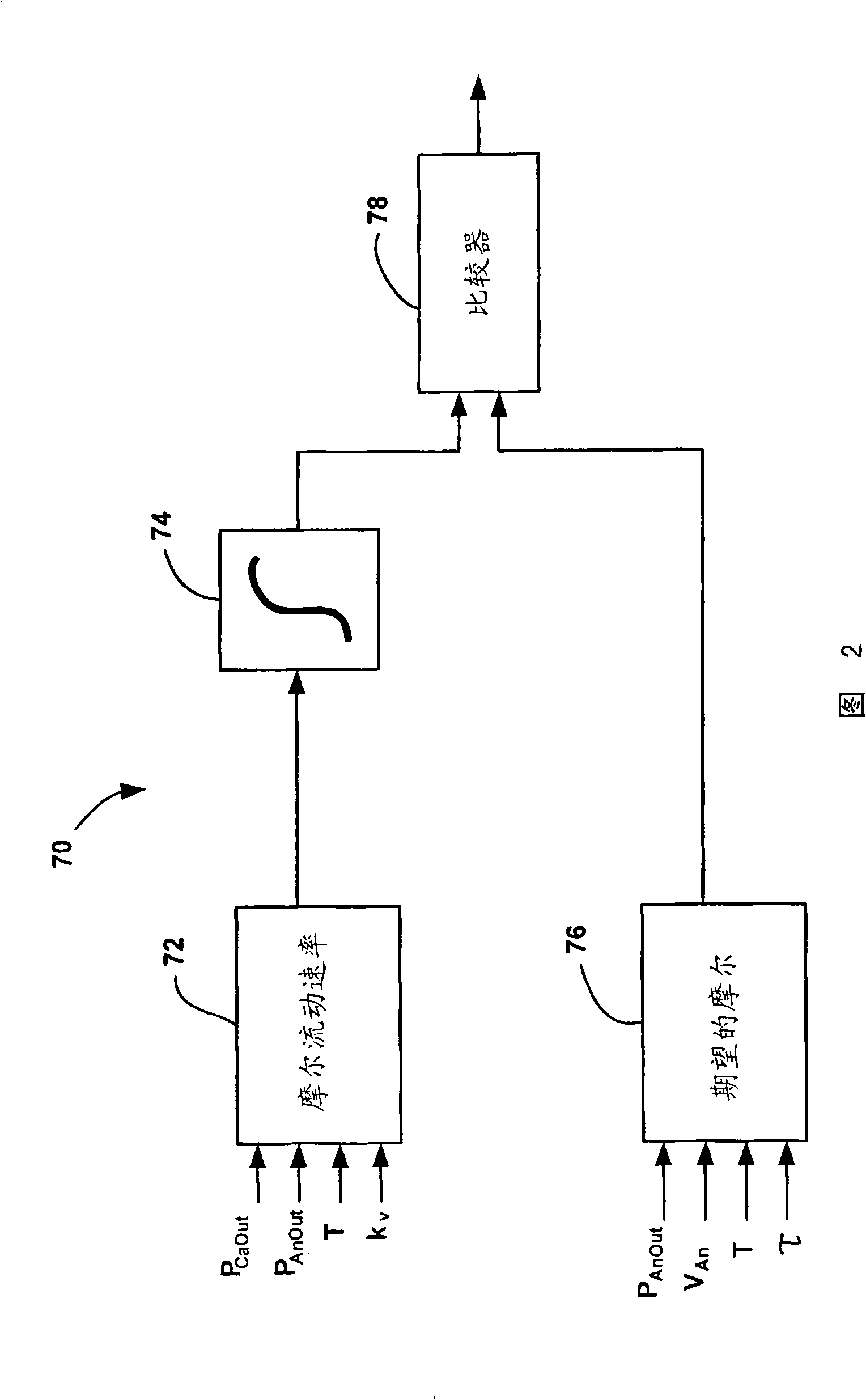

[0014] FIG. 1 is a schematic structural diagram of a fuel cell system 10 including a first split fuel cell stack 12 and a second split fuel cell stack 14. The compressor 16 provides the cathode input air on the cathode input line 18 to the separated cell stacks 12 and 14 through the normally closed cathode input valve 20. The cathode exhaust gas is output from the separation cell stack 12 through a line 24, and the cathode exhaust gas is output from the separation cell stack 14 through a line 26, and these cathode exhaust gases are mixed into a separate cathode output line 28. The normally closed cathode back pressure valve 30 controls the flow of cathode exhaust gas through the line 28. The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com