Gas-sensitive sensor

A gas sensor and gas-sensitive technology, which is applied in the field of gas sensors, can solve the problems of increasing device power consumption, increasing device lead-out lines, manufacturing complexity, and lack of devices, so as to reduce device power consumption, simplify device design and The effect of manufacturing complexity and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

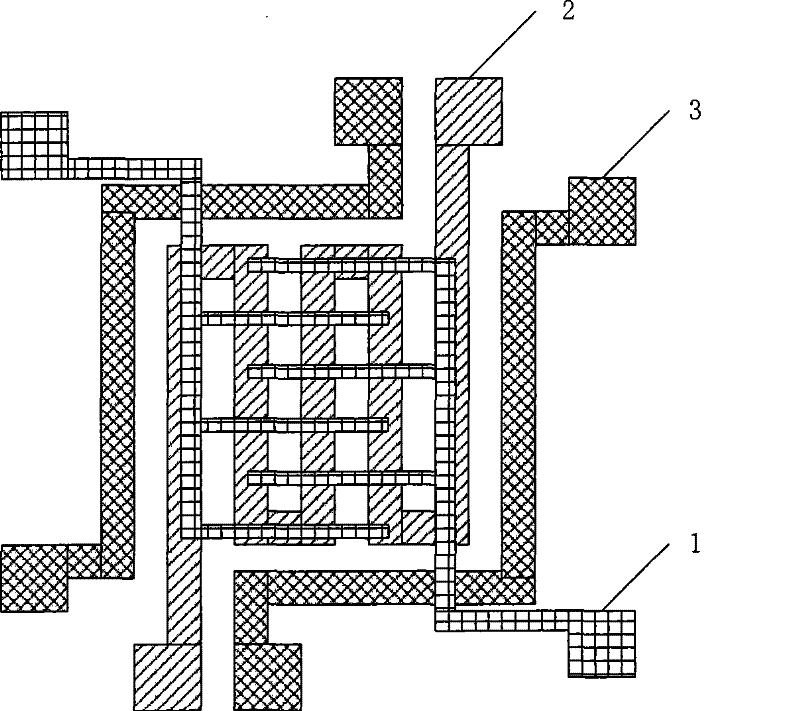

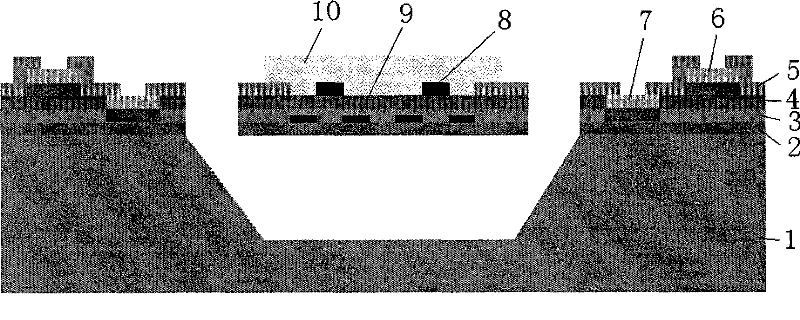

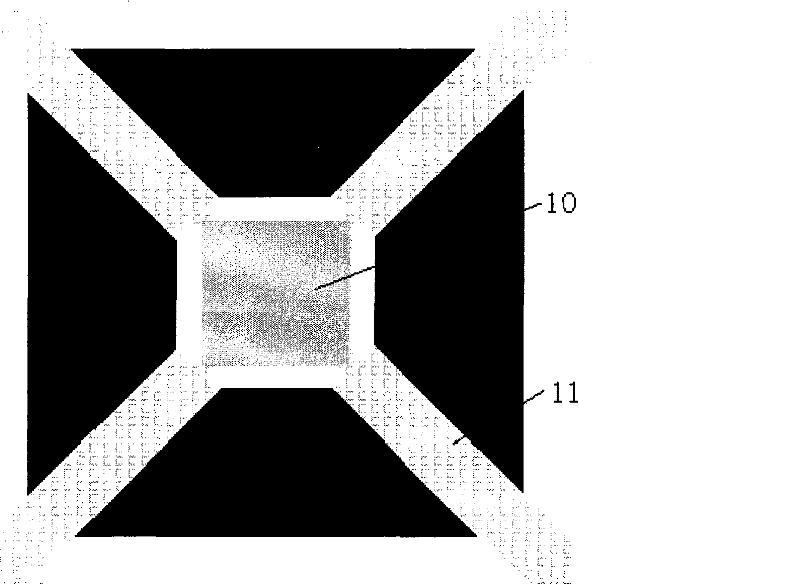

[0039] Refer again figure 2 , 3 , 4 and 5, the device is mainly composed of silicon substrate (1), silicon dioxide / silicon nitride layer (2), silicon dioxide electrical insulating layer (3), silicon nitride electrical insulating layer (4), silicon dioxide Layer (5), Au / Cr layer (6) of interdigitated electrode leads, Au / Cr layer (7) of heating and temperature measuring electrodes, Pt / Ti layer of interdigitated electrodes (8), heating and temperature measuring electrodes (9) and ten parts of the tin dioxide gas sensitive layer (10).

[0040]The silicon substrate is mainly used as a supporting structure, and the device is fixed on the silicon substrate through the support arm (11). The anisotropic etching of silicon by KOH is used to etch away the silicon below the device to form a cavity, so as to increase the distance between the device and the surrounding area. Thermal insulation, interdigital electrodes and heating temperature measurement electrodes are connected with powe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com