Method and apparatus for measuring thin film non-uniform stress on line

A measuring device and non-uniform technology, applied in the direction of measuring device, measuring force, using optical devices, etc., can solve the problems of consuming a lot of time, not being able to realize curvature full-field measurement, vibration sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific structure and implementation mode of the present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention should not be limited thereby.

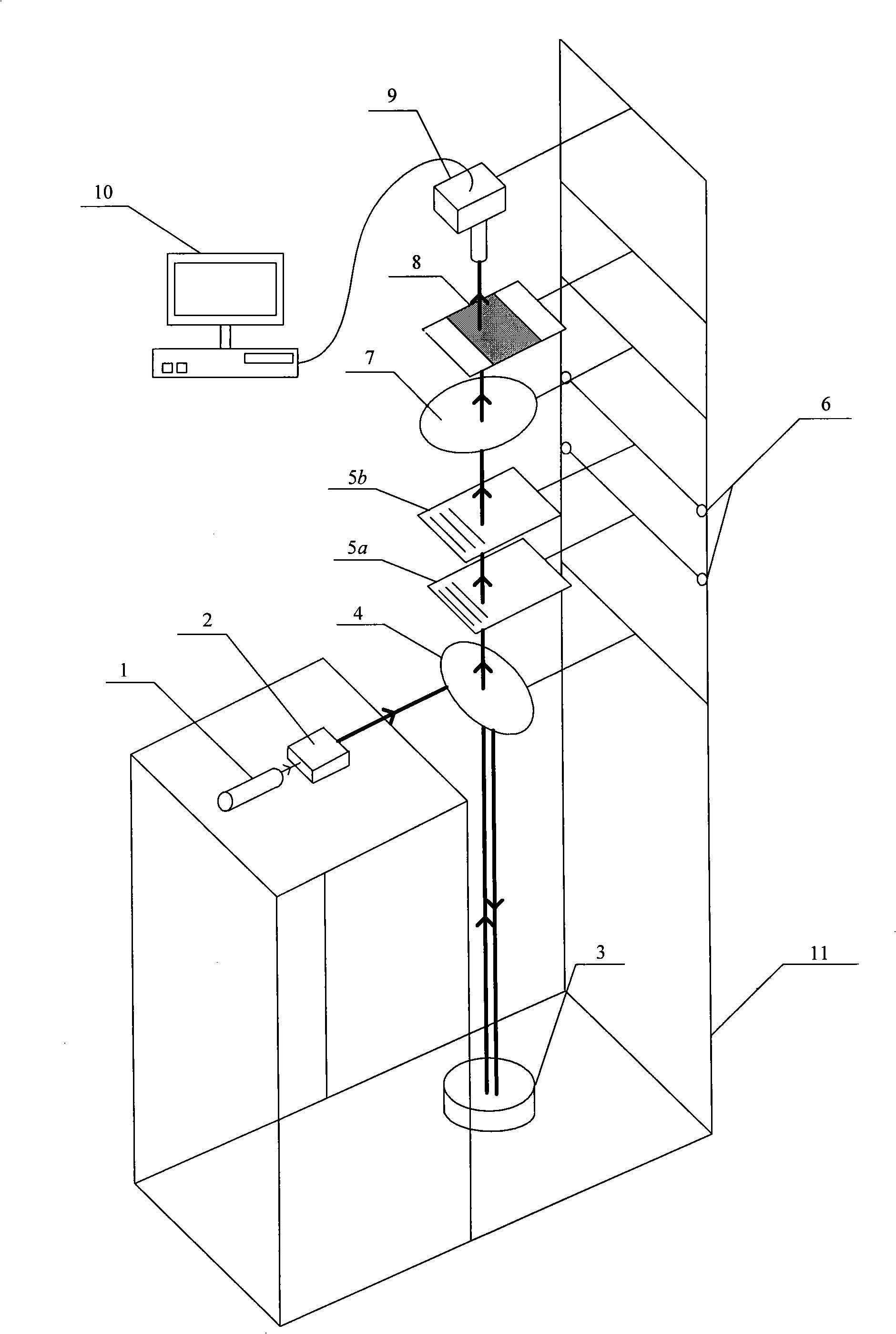

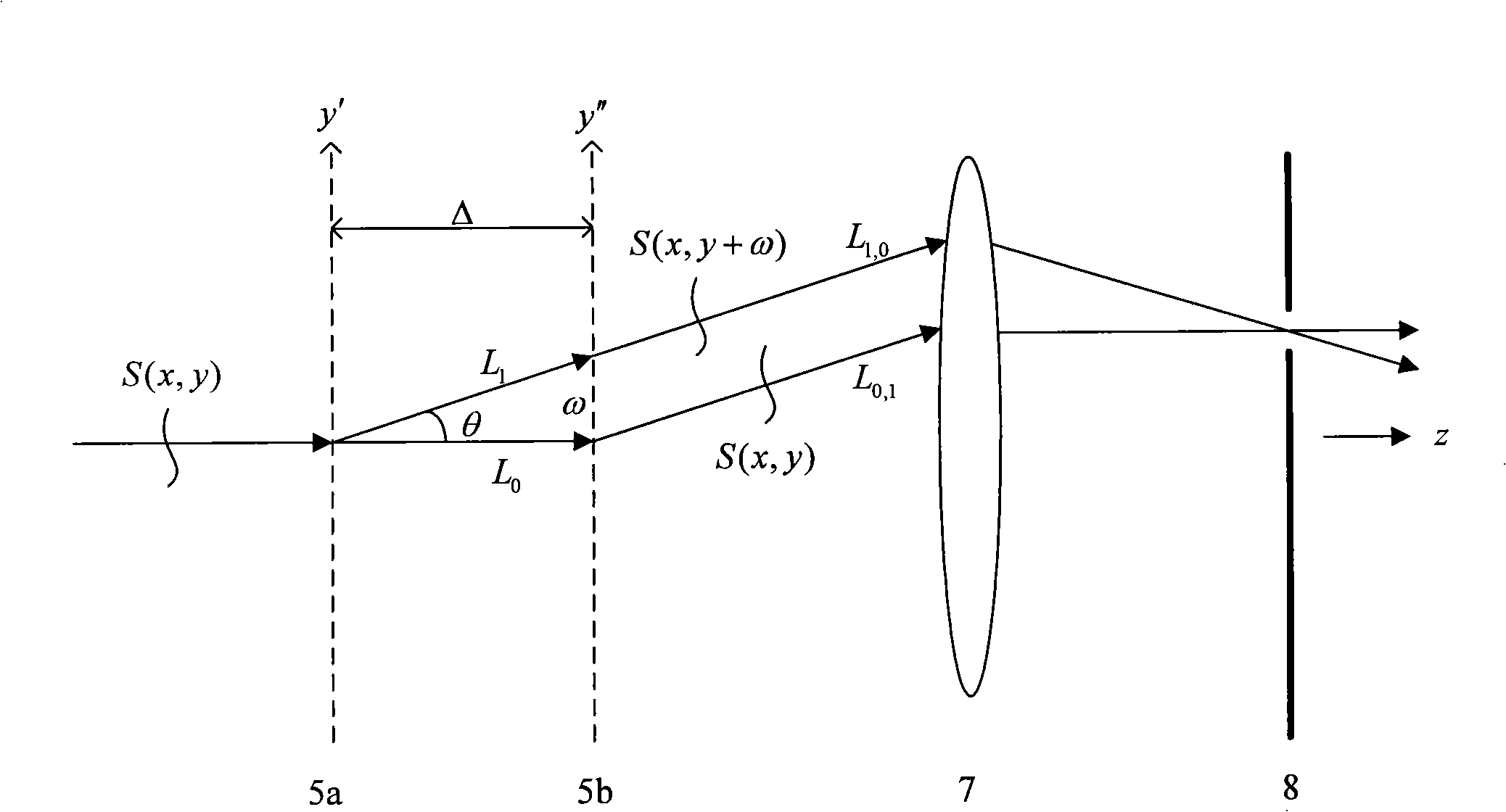

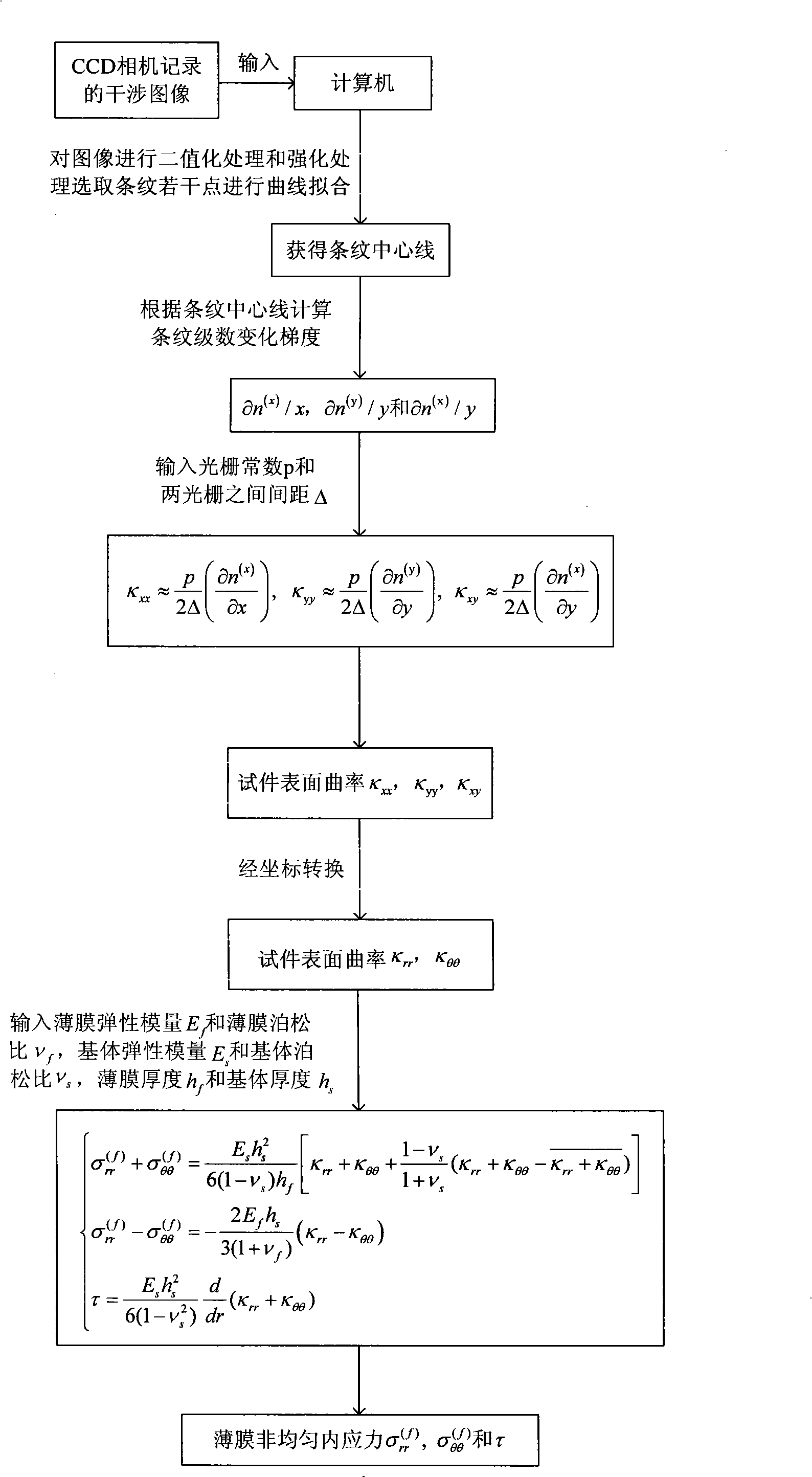

[0033] figure 1It is a structural schematic diagram of the device for on-line measurement of non-uniform stress in thin films according to the present invention. The device includes a laser 1, a beam expander 2, a beam splitter 4, a specimen loading platform 3, a first grating 5a located above the beam splitter 4, and a second Grating 5b, lens 7, filter screen 8, CCD camera 9, the computer 10 that is connected with CCD camera 9 and the servomotor 6 that is used for adjusting the distance between the first grating and the second grating; After the beam device 2 and the beam splitter 4, the light beam reflected by the beam splitter 4 reaches the test piece on the test piece loading platform 3, and the light beam reflected by the test piece pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com