Novel methods for treating phenolic waste water pollution by phenol water coal slurry method

A technology of phenol water slime and phenol wastewater, which is applied in the field of harmless and thorough treatment, can solve the problems of organic matter enrichment, phenol pollution that cannot be effectively and completely solved, and can not be treated, so as to improve utilization rate and solve accumulation and pollution problems, money-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

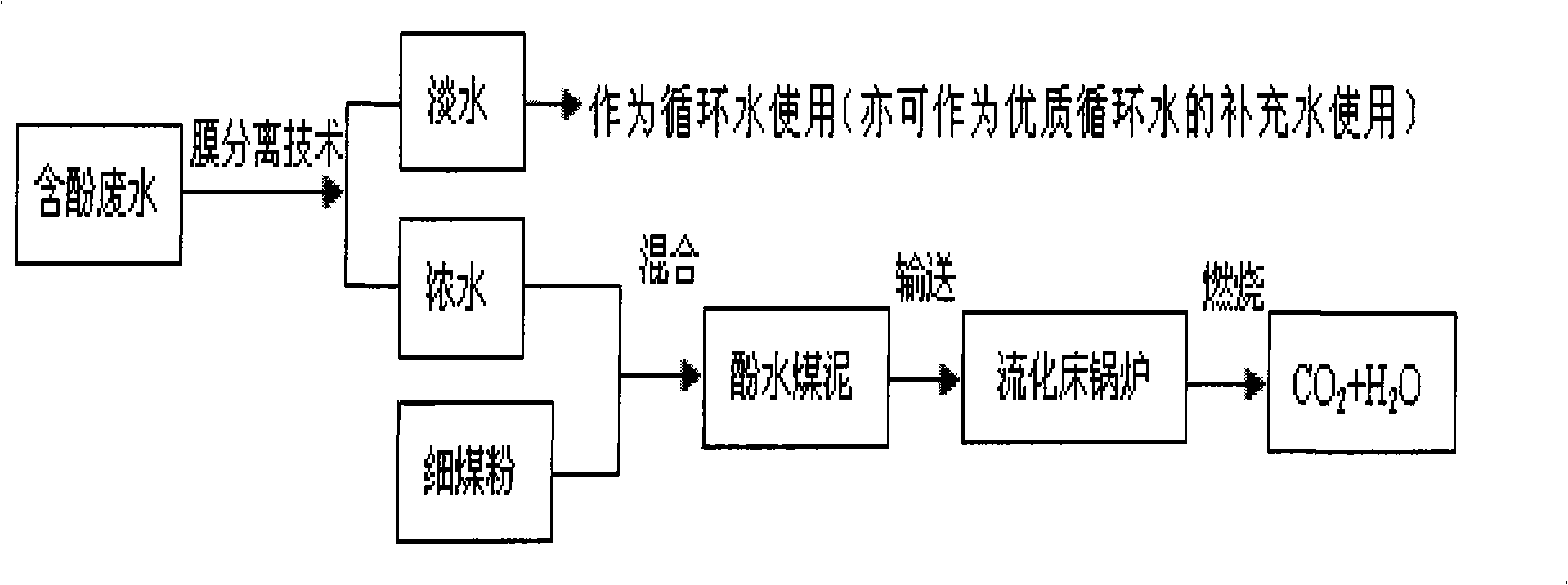

[0053] Adopt the new method of phenol-water slime method to control the pollution of phenol-containing wastewater, and its composition comprises: concentrate phenol-containing wastewater, then:

[0054] A. the described phenol-containing waste water is improved wherein phenol concentration by membrane filtration, discharges clear water, has reduced the volume of phenol-containing waste water;

[0055] B. Mix the concentrated water and pulverized coal to make phenol water slime;

[0056] C. Use the slime transportation technology to transport the phenol-water coal slime to the fluidized bed boiler for combustion treatment, so that the high-concentration phenol-containing wastewater is cracked and burned in the boiler;

[0057] D. Output the energy obtained from combustion in the form of heat or electricity.

Embodiment 2

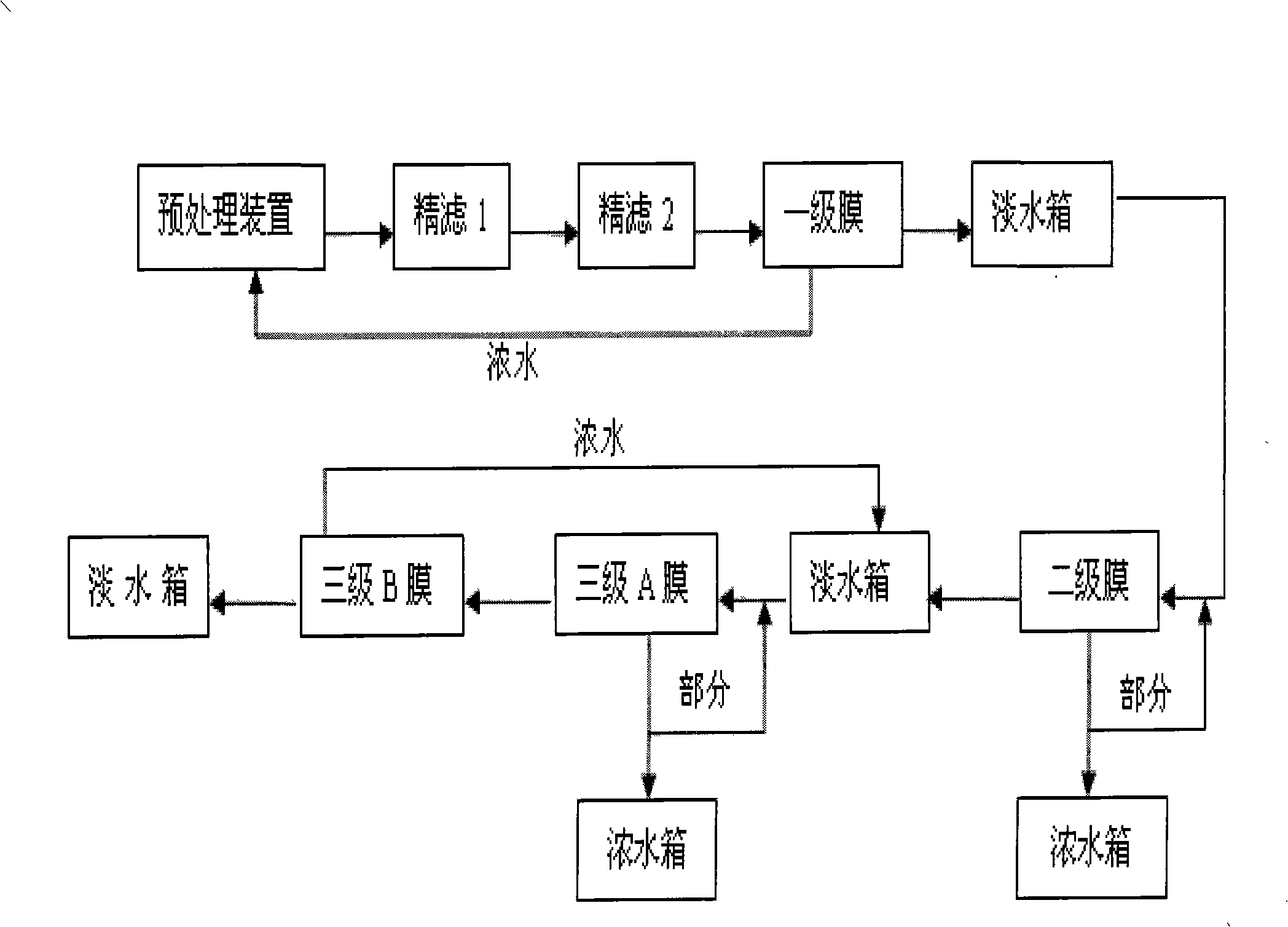

[0059] The new method of adopting phenol-water slime method to control phenol-containing wastewater pollution described in embodiment 1, the membrane filtration is multi-stage membrane filtration, the concentrated water produced after each stage of filtration is discharged to the high concentration water tank, and the fresh water produced is returned to the high-concentration water tank. use.

[0060] (1) Fine filtration

[0061] This solution uses a precision filter that can remove particulate impurities above 1 micron, and the filter element is a wire-wound filter element. The shell of the precision filter is made of stainless steel, and the flange is fixed between the cylinder body and the head, so it is very convenient to replace the filter element. The filtration rate of the filter element is 8m 3 / m 2 h, not only removes particulate impurities, but also removes chroma, turbidity, soluble organic pollutants, low-molecular organic substances, etc., intercepts mechanical...

Embodiment 3

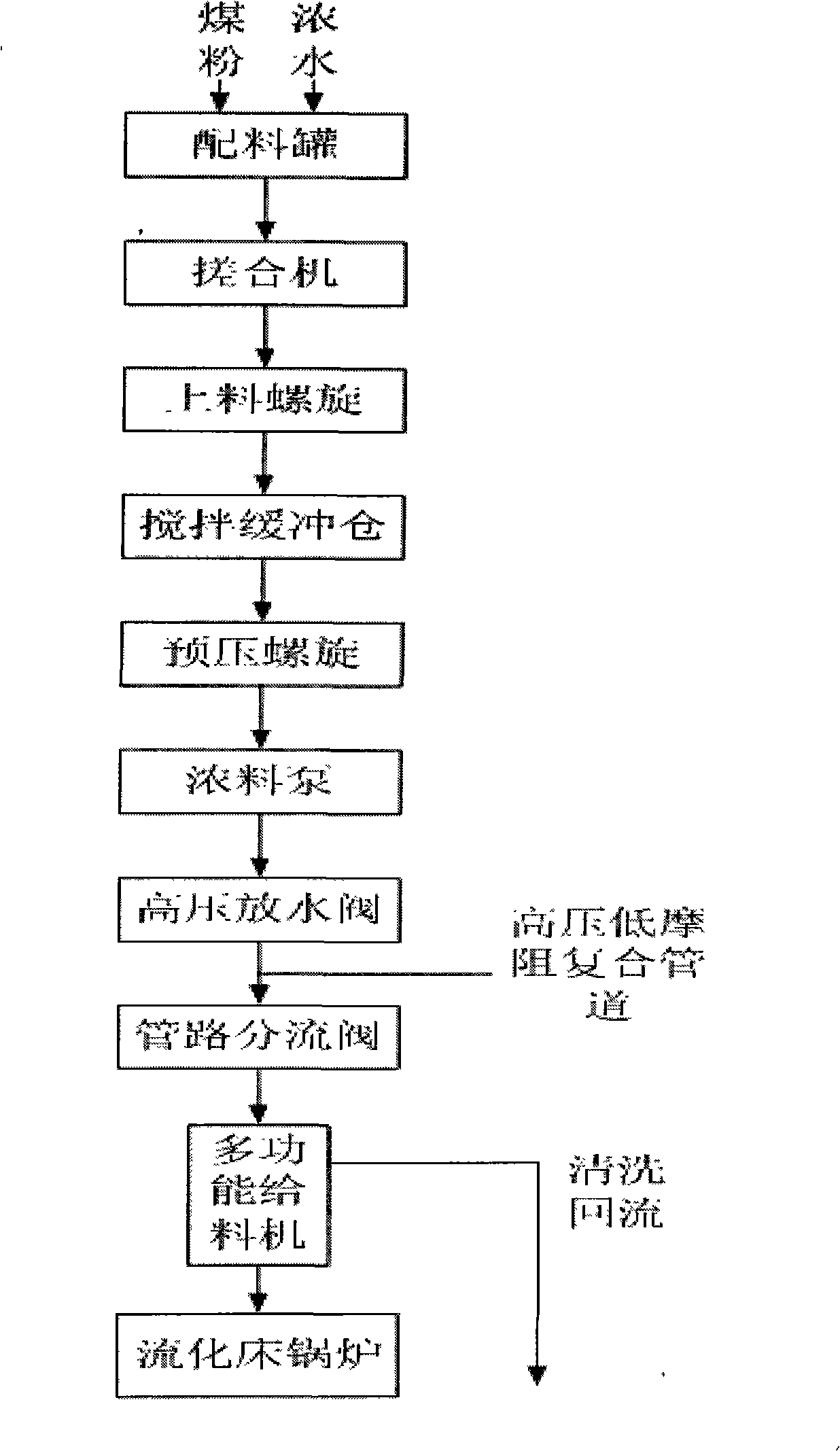

[0081] The new method of using the phenol-water slime method to control phenol-containing wastewater pollution, the production and transportation flow chart of the phenol-water slime are as follows image 3 shown. Phenol-containing wastewater concentrated water and fine coal powder are used to make phenol-water slime, which is transported to the fluidized bed through the slime pipeline system. Coal slime transportation technology is through the coal slime pipeline transportation system. In order to ensure the transportation speed, the method of increasing the pressure and concentration can be used for long-distance transportation. In order to avoid pollution, it should be transported in a fully enclosed pipeline transportation method. After arriving at the destination, through the kneading machine, feeding screw, stirring buffer tank, pre-pressing screw, inspection gate, concentrated material pump, high-pressure and low-friction composite pipeline, high-low pressure concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com