Valve

A valve shell and valve technology, applied in the field of valves, can solve the problems of affecting the activity of the spring tongue, the tendency of valve error is large, hindering serial mass production, etc., to achieve the effect of ensuring torque balance and simple suspension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

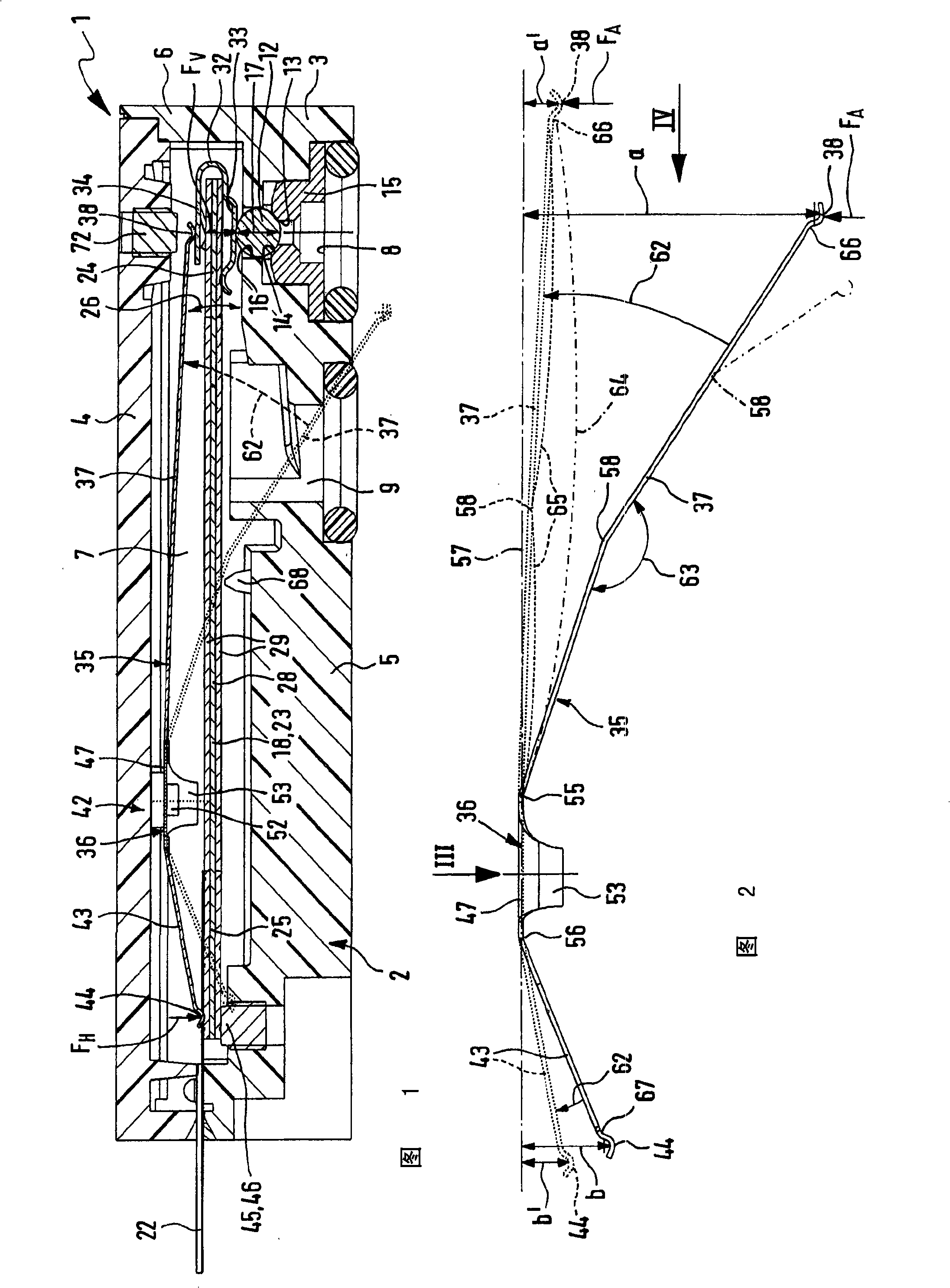

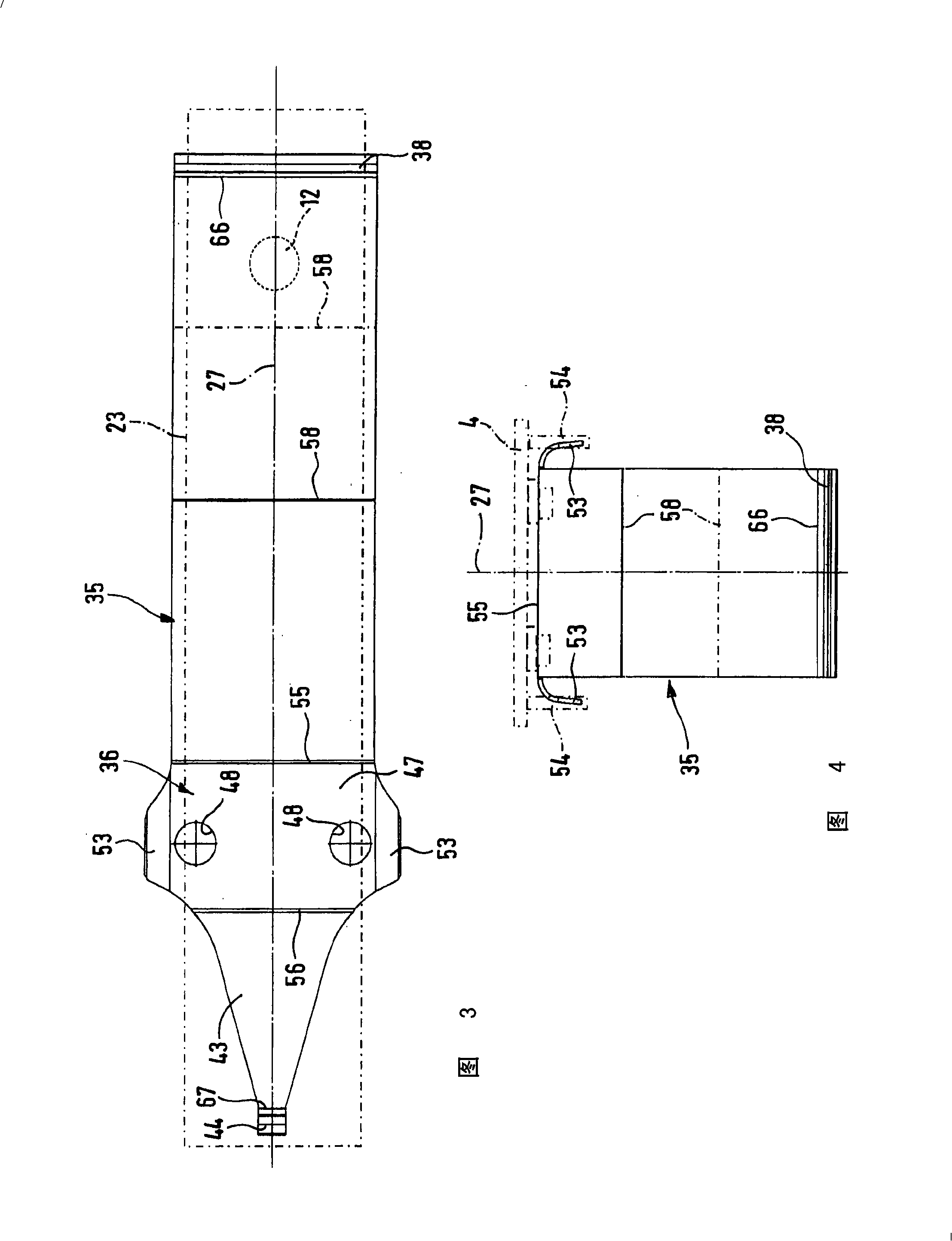

[0033] FIG. 1 shows a preferred embodiment of a valve 1 designed according to the invention as a piezoelectric valve. Of course, the invention is also suitable for valve types with other operating concepts.

[0034]FIG. 1 contains a valve housing 2 which is preferably composed of a valve housing body part 3 and a valve housing cover part 4 fixed thereon in a sealing manner. The valve housing body part 3 has a bottom wall 5 and a side wall 6 protruding from the bottom wall, the valve housing cover part 4 is arranged on the end region of the side wall 6, so that the valve housing cover part and the valve housing body part 3 jointly form a valve chamber 7. The valve housing cover 4 can be inserted at least partially into the valve housing body part 3 . Preferably, the valve housing cover part 4 is glued or welded to the valve housing body part 3 in a sealing manner.

[0035] The valve 1 of the present embodiment is designed as a 2 / 2-directional valve, although other functions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com