Valve plate of gate valve and method for manufacturing the same

A manufacturing method and valve plate technology, applied in the direction of valve operation/release device, sliding valve, valve details, etc., can solve the problems of easy wear of sealing contact surface, wear of sealing material, unresolved gate valve, etc., and achieve enhanced connection firmness The effect of high reliability, strong connection, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

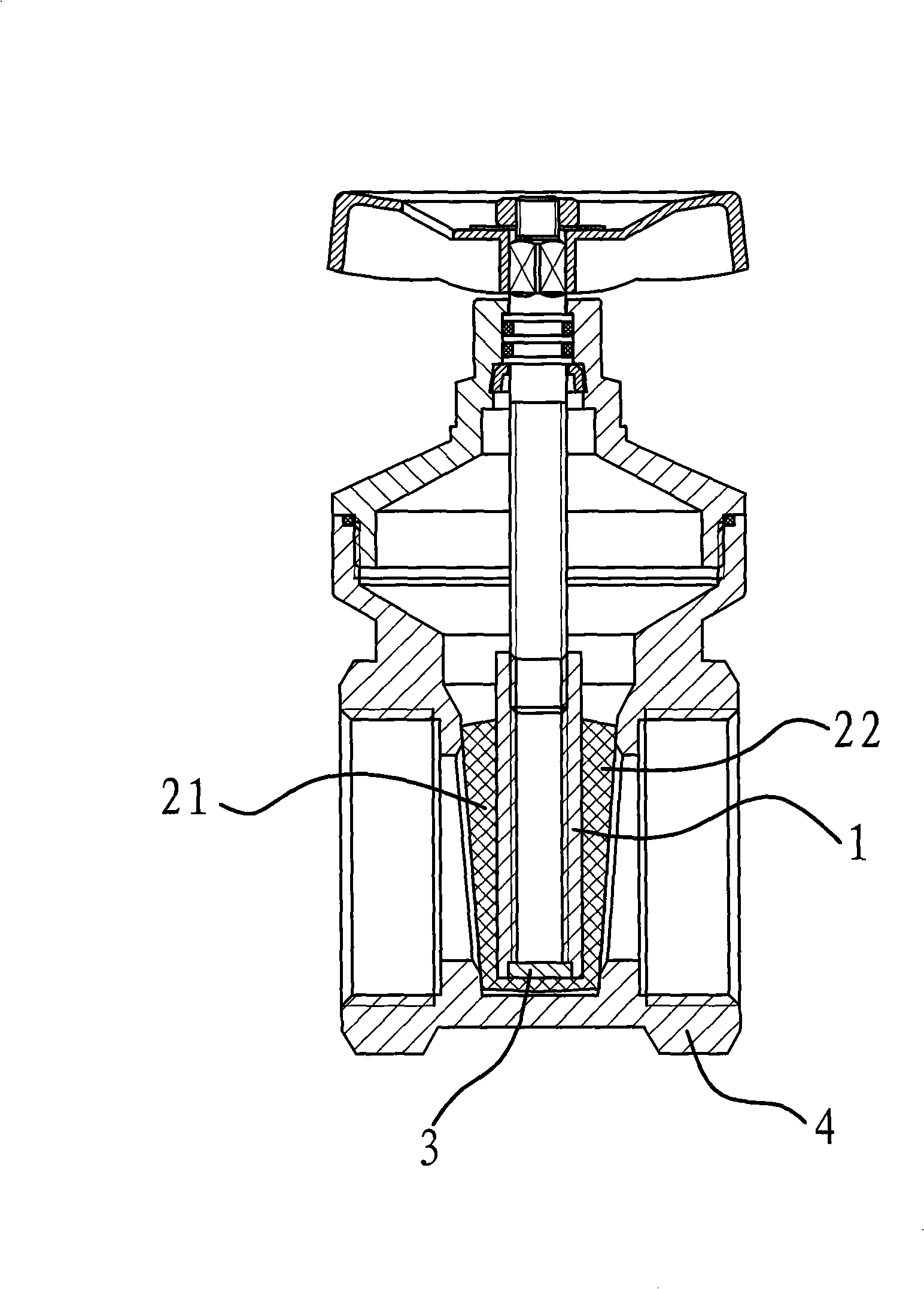

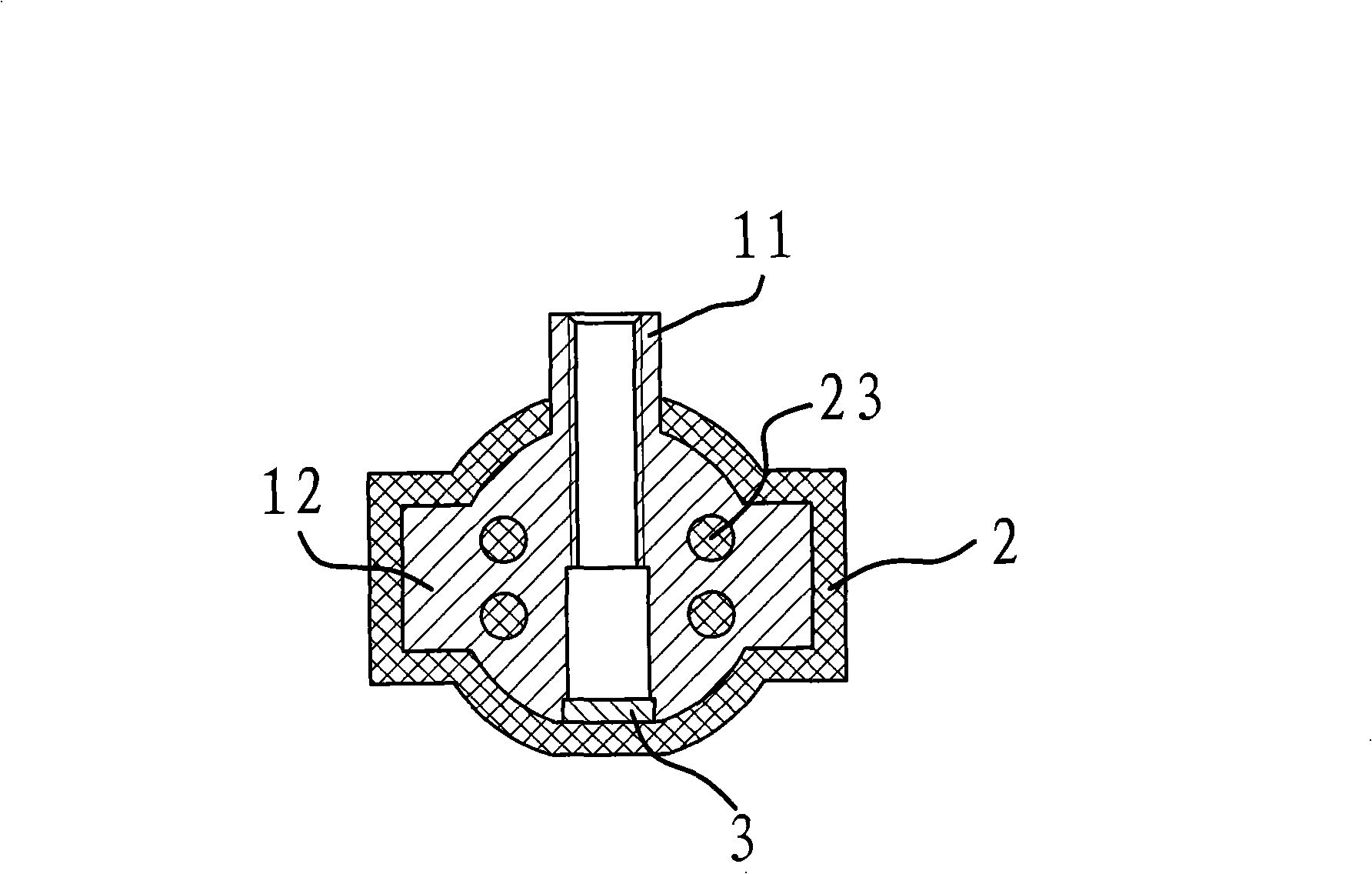

[0034] like figure 1 , figure 2 and image 3 As shown, the valve plate of the gate valve of the present invention is set in the valve body 4 of the gate valve, including a copper plate 1 and a rubber inclusion 2 coated and fixed on the outside of the copper plate 1 .

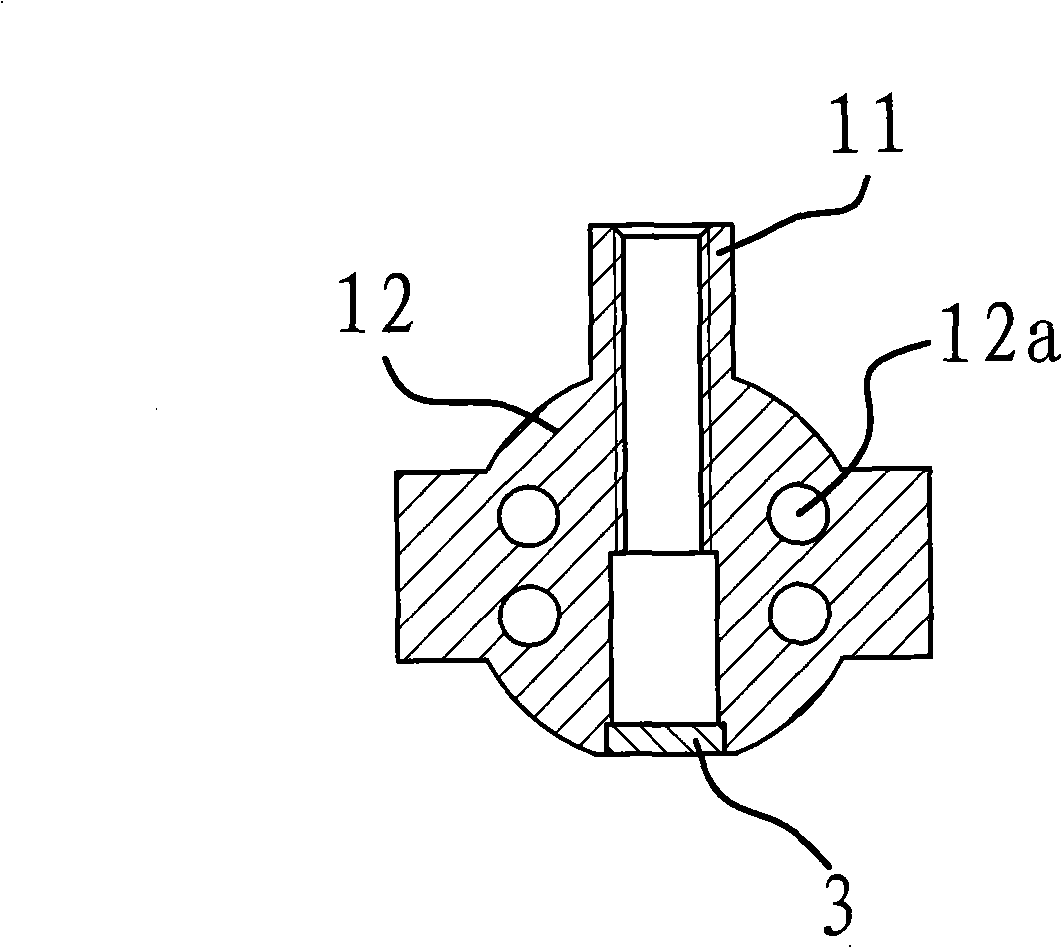

[0035] The copper plate 1 includes a tubular rod body 11 and two boards 12 fixed on the rod body 11, the board body 12 is connected with the rod body 11 as a whole, the two board bodies 12 are on the same plane, and each board body 12 is provided with There are two through holes 12a. The plate 12 acts as a guide when it is installed in the valve body 4 .

[0036] The rubber enclosure 2 includes a left part 21 and a right part 22, the left part 21 and the right part 22 are respectively divided into two sides of the copper plate 1, and the edge and the bottom of the left part 21 are connected with the edge and the bottom of the right part 22 respectively, The entire inclusion 2 is covered on the outer surface...

Embodiment 2

[0048] During the molding process of the valve plate of the gate valve, the heating temperature of the mold is 160° C., and other technological processes are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0050] During the molding process of the valve plate of the gate valve, the heating temperature of the mold is 180° C., and other technological processes are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com