Bimetallic strip stepless variable drive

A technology of stepless speed change and transmission, applied in the direction of transmission, transmission control, and components with teeth, etc., can solve the problems of large axial size, energy consumption structure, complex structure, etc., and achieve large speed range and volume Small, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

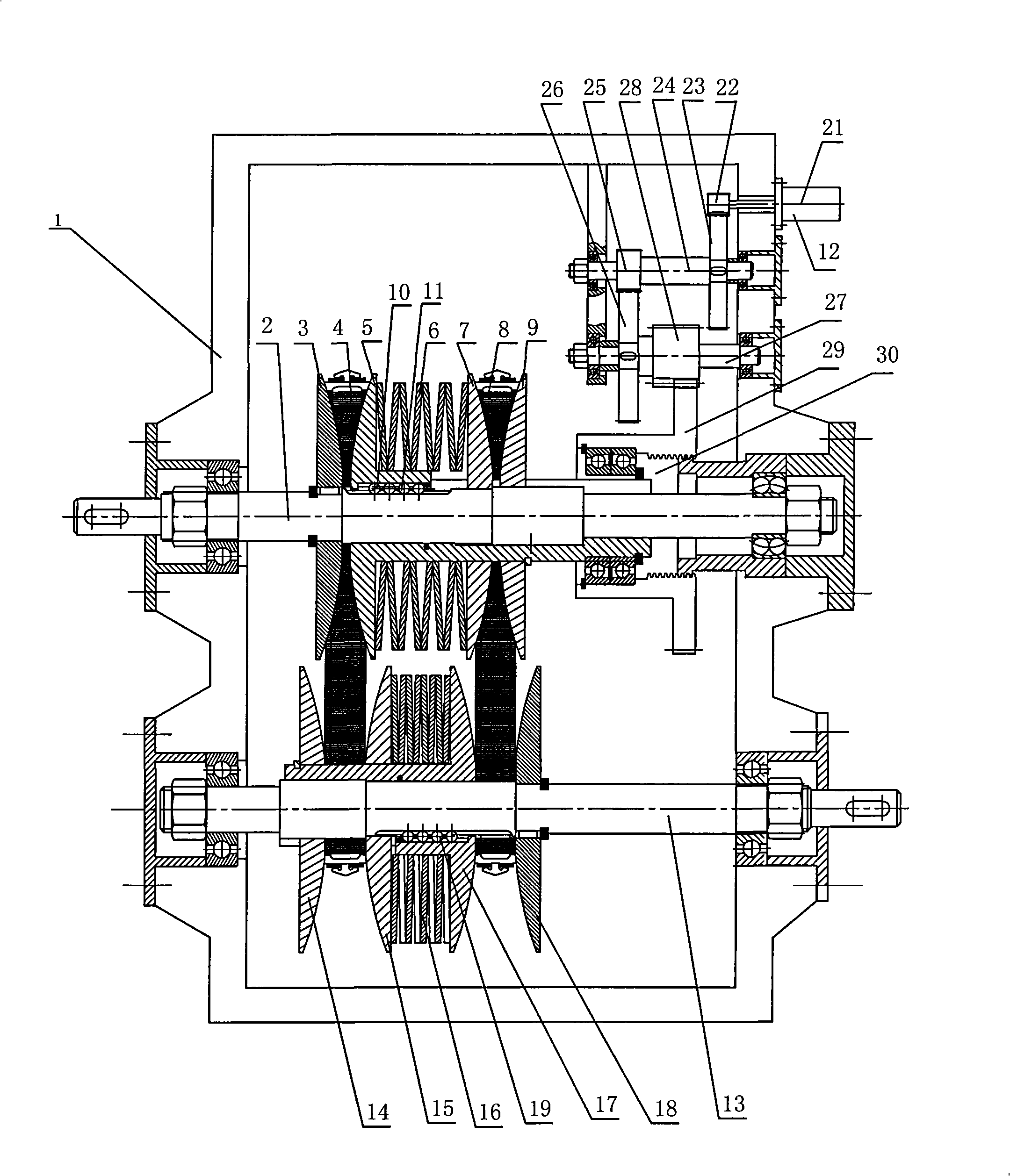

[0013] As shown in the figure, 1-supporting box, 2-driving shaft, 3-left driving fixed cone, 4-left metal belt, 5-left driving moving cone, 6-balance spring, 7-right driving fixed cone, 8-right metal belt, 9-right driving cone, 10-connecting ball key, 11-first sleeve, 12-governing mechanism, 13-driven shaft, 14-left driven cone, 15- Left driven fixed cone, 16-pressure spring, 17-right driven fixed cone, 18-right driven fixed cone, 19-second sleeve, 21-speed regulating motor, 22-transition gear, 23 - transmission first gear, 24-first gear shaft, 25-axis gear, 26-transmission second gear, 27-second gear shaft, 28-two-tooth gear, 29-gear nut, 30-screw;

[0014] The double metal belt continuously variable transmission device of the present invention includes a support box 1, a driving shaft 2 and a driven shaft 13 arranged in the support box 1, and a left driving fixed cone 3 is fastened on the driving shaft 2 , a left active movable cone 5 is movable, and the left active movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com