Spring spindle

A technology of spindles and compression springs, applied in the field of spring spindles, can solve the problems of insufficient pay-off speed, high resistance of wire tubes, and short service life, so as to improve weaving quality and production efficiency, reduce the number of broken wires, and improve the quality of threading. long distance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

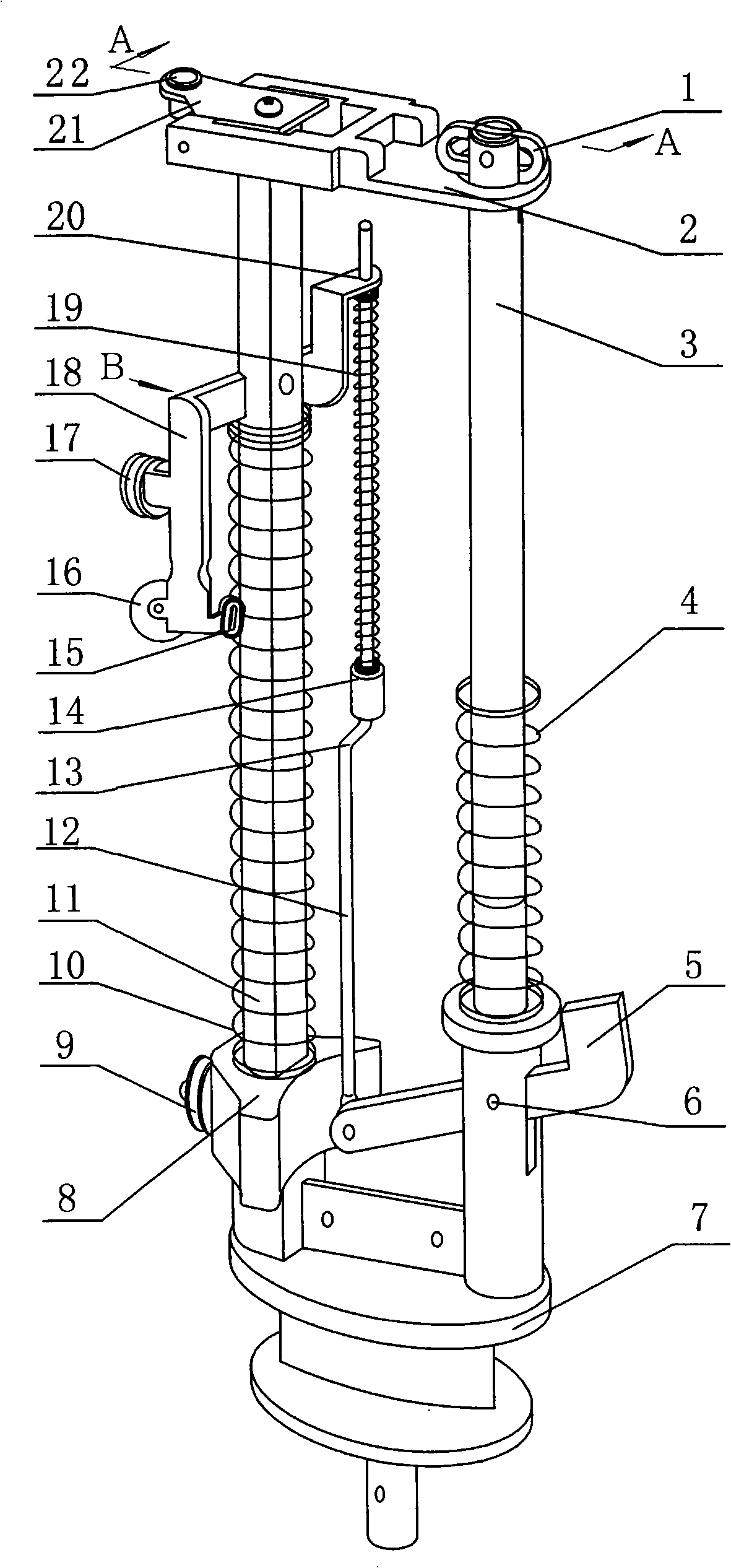

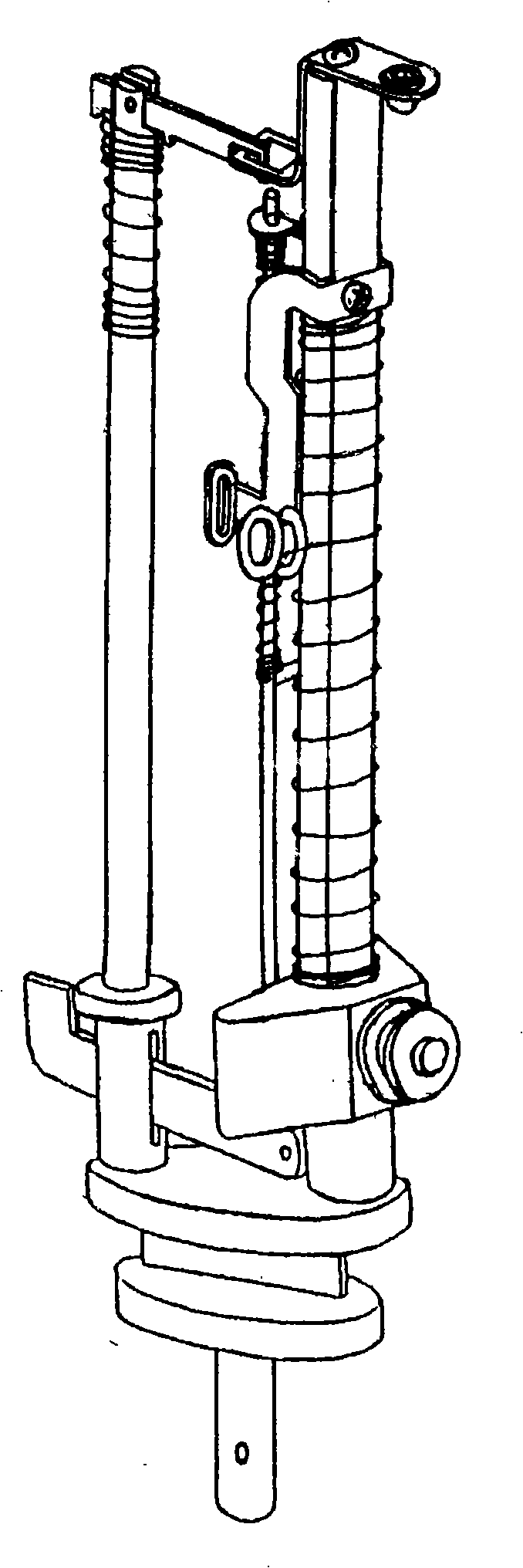

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] Left and right columns 3,11 are die-cast in two through holes at the top of the runway bar 7, and are fixed into one body to form a fixture.

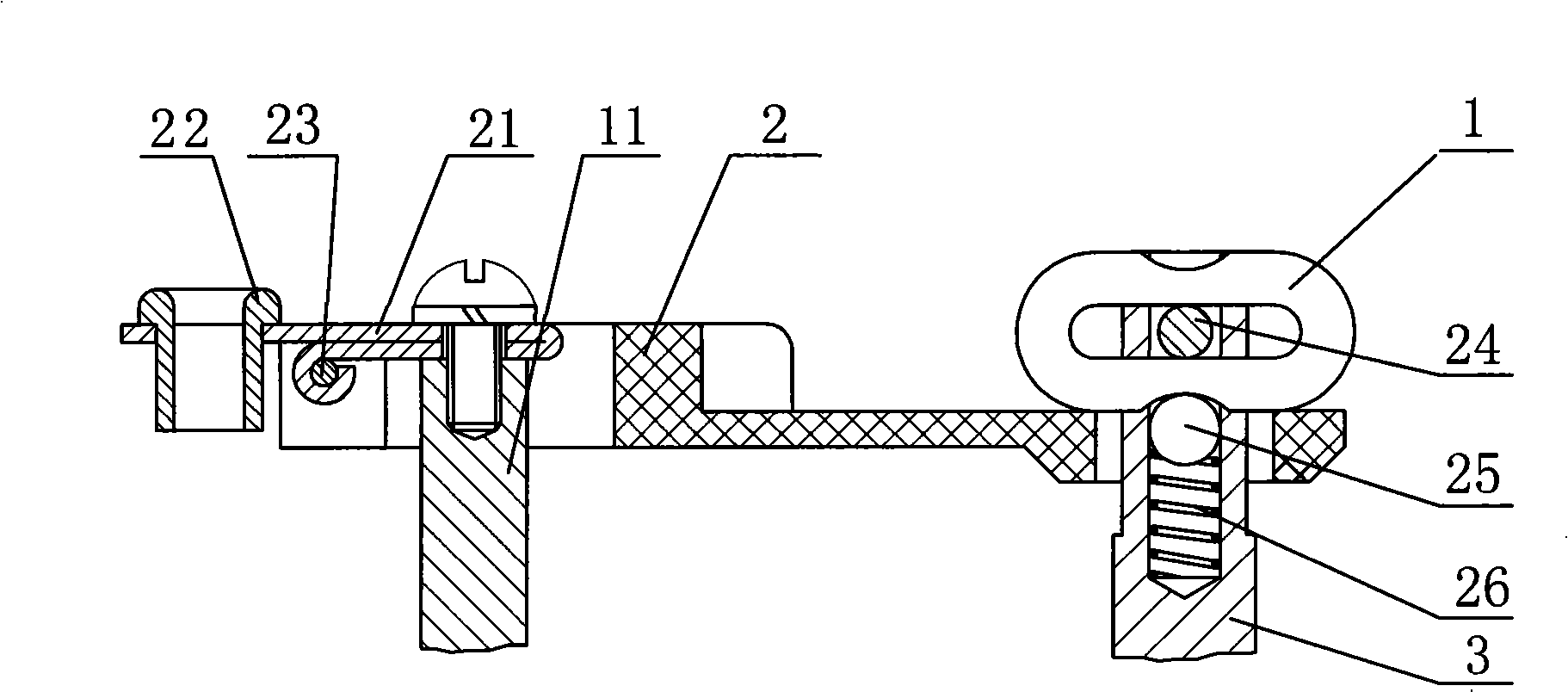

[0016] Left column 3 cylinders, there is an open slot in the middle of the top, small spring 26, steel ball 25 are placed in the slot, two corresponding through holes communicated with the middle open slot are arranged on the front and back walls of the open slot, pass two with pin 24 The through hole connects the slide button 1 with the waist hole in the middle to the opening groove of the left column, the slide button 1 can rotate around the pin 24, and cooperates with the small spring 26 and the steel ball 25.

[0017] Right column 11 sections are waist-shaped, and screw hole is arranged on the top.

[0018] The track bar 7 is the same as the prior art by injection molding of composite material, wear-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com