Bendable glued board and preparation method thereof

A plywood and bending technology, which is applied in the field of plywood, can solve the problems of consuming solid wood and increasing manufacturing costs, and achieve the effects of improving work efficiency, beautifying life, and saving solid wood resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

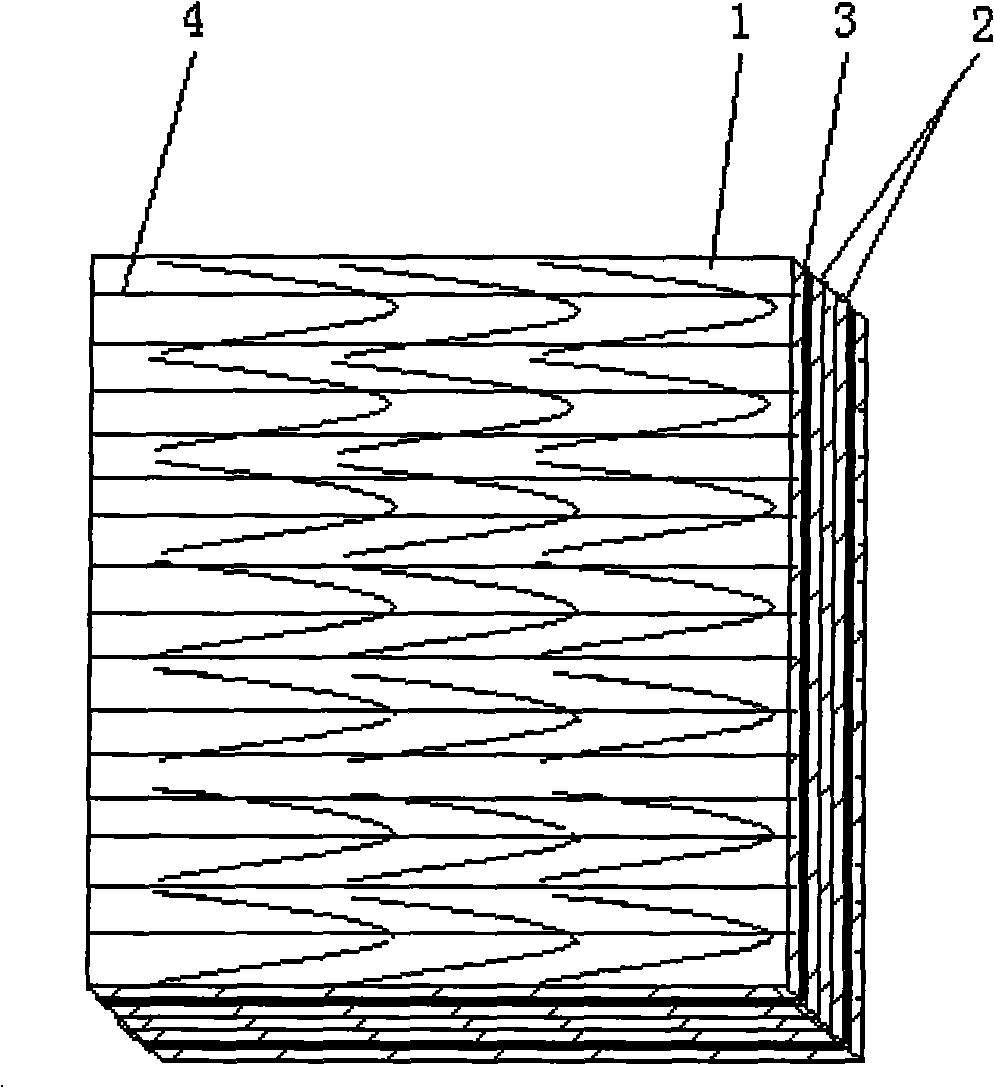

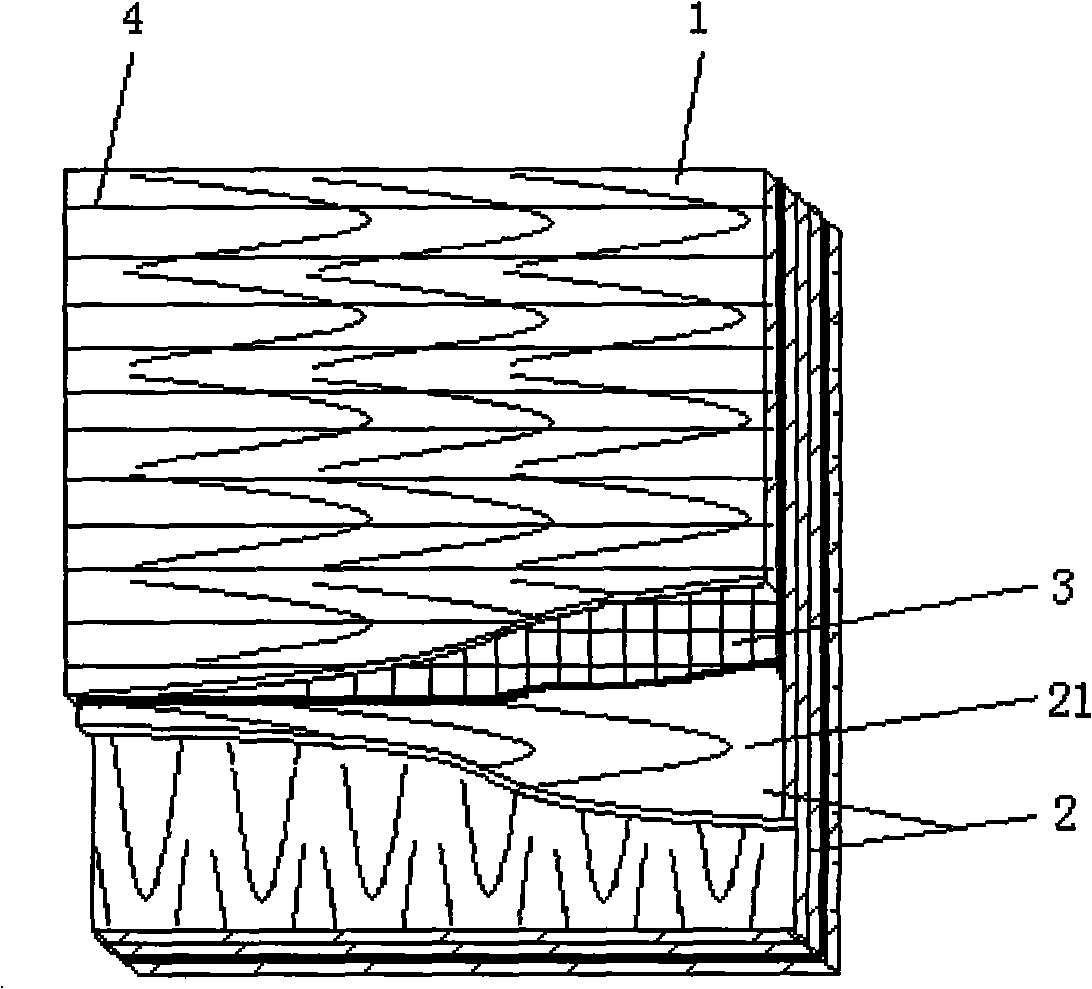

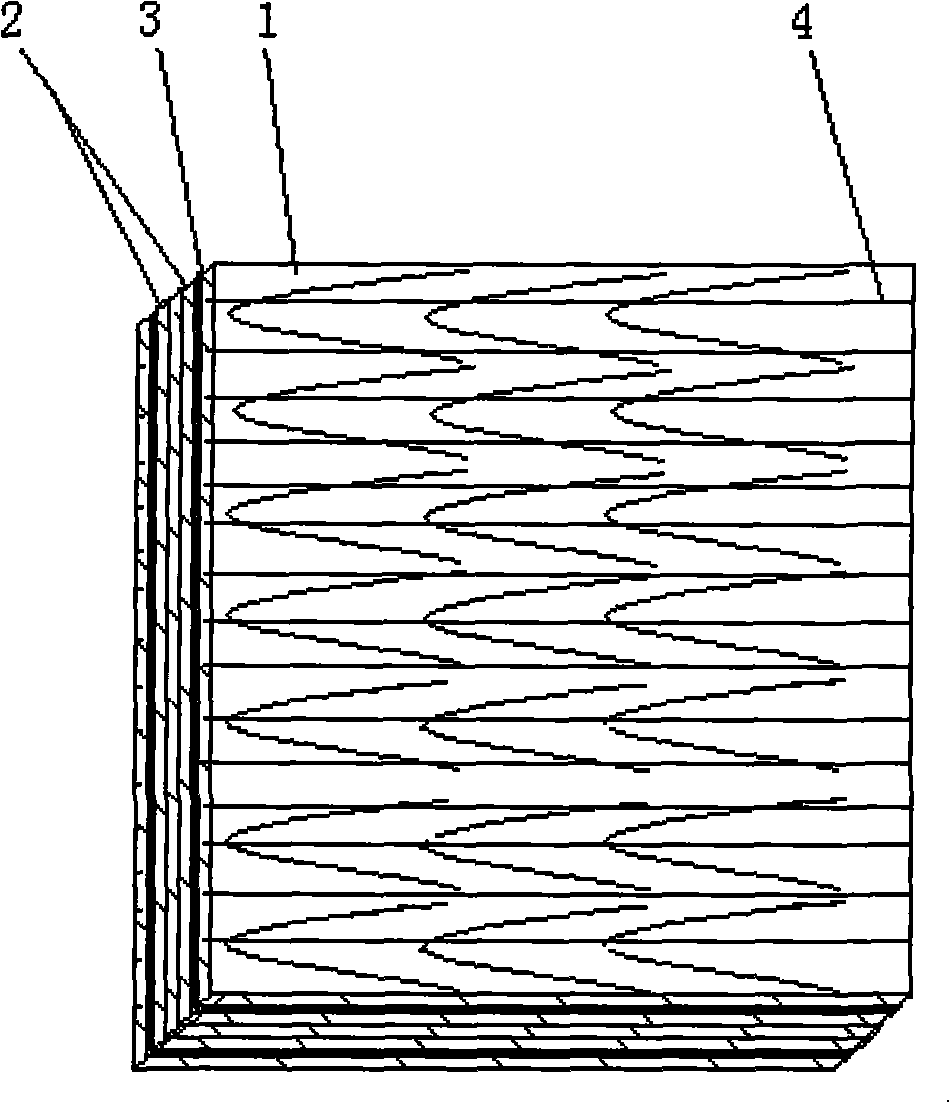

[0023] Such as figure 1 , 2 As shown in 3, the bendable plywood of the present invention includes a surface layer and an intermediate layer. A plant fiber layer 3 is arranged between the surface layer 1 and the middle layer 2 on both sides. The middle layer 2 has 3 layers, and the wood fiber pattern in the middle layer is perpendicular to the wood fiber pattern of the surface layer 1, and the thickness of this layer is 14% of the total thickness of the plywood.

[0024] Still as figure 1 , 3 As shown, gaps 4 are provided on the surface layers 1 on both sides. The gap 4 is parallel to the wood fiber pattern of the surface layer 1, the distance between the two gaps 4 is 3 mm, and the depth of the gap 4 is 3 / 5 of the thickness of the surface layer 1.

[0025] The preparation method of bendable plywood includes the following steps:

[0026] (1) Apply glue on the surface of the intermediate layer 2 according to the conventional method, cover the plant fiber layer 4 on the intermediat...

Embodiment 2

[0031] Such as figure 1 , 2 As shown in 3, the bendable plywood of the present invention includes a surface layer and an intermediate layer.

[0032] A plant fiber layer 3 is arranged between the middle layer 21 and the middle layer 2 on both sides. The middle layer 21 has five layers. The wood fiber texture of the middle layer is perpendicular to the wood fiber texture of the surface layer 1. The thickness is 15% of the total thickness of the plywood. (Illustration not provided)

[0033] Still as figure 1 , 2 As shown in 3, gaps 4 are provided on the surface layers 1 on both sides. The gap 4 is parallel to the wood fiber pattern of the surface layer 1, the distance between the two gaps 4 is 2 mm, and the depth of the gap 4 is 9 / 10 of the thickness of the surface layer 1.

[0034] The preparation method of bendable plywood includes the following steps:

[0035] (1) Apply glue to the surface of the intermediate layer 2 according to the conventional method, cover the plant fiber l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com