Powder-coating machine for duplex metal compound material

A composite material and bimetallic technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of environmental pollution, low production efficiency, and operator injury, and achieve high dimensional accuracy and high production efficiency , the effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

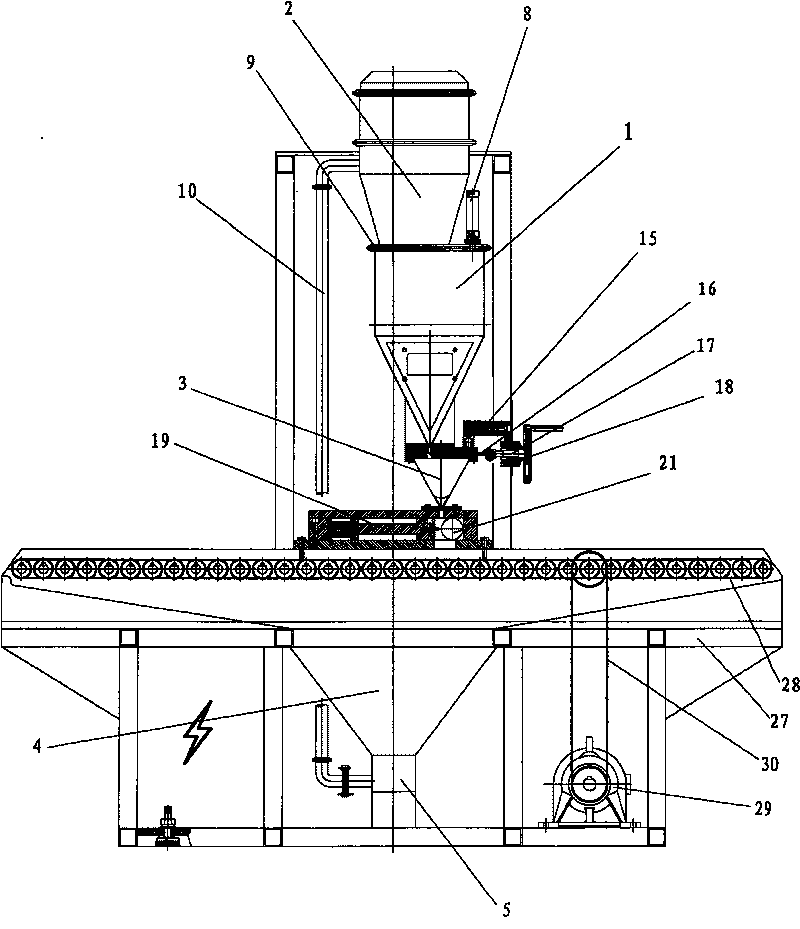

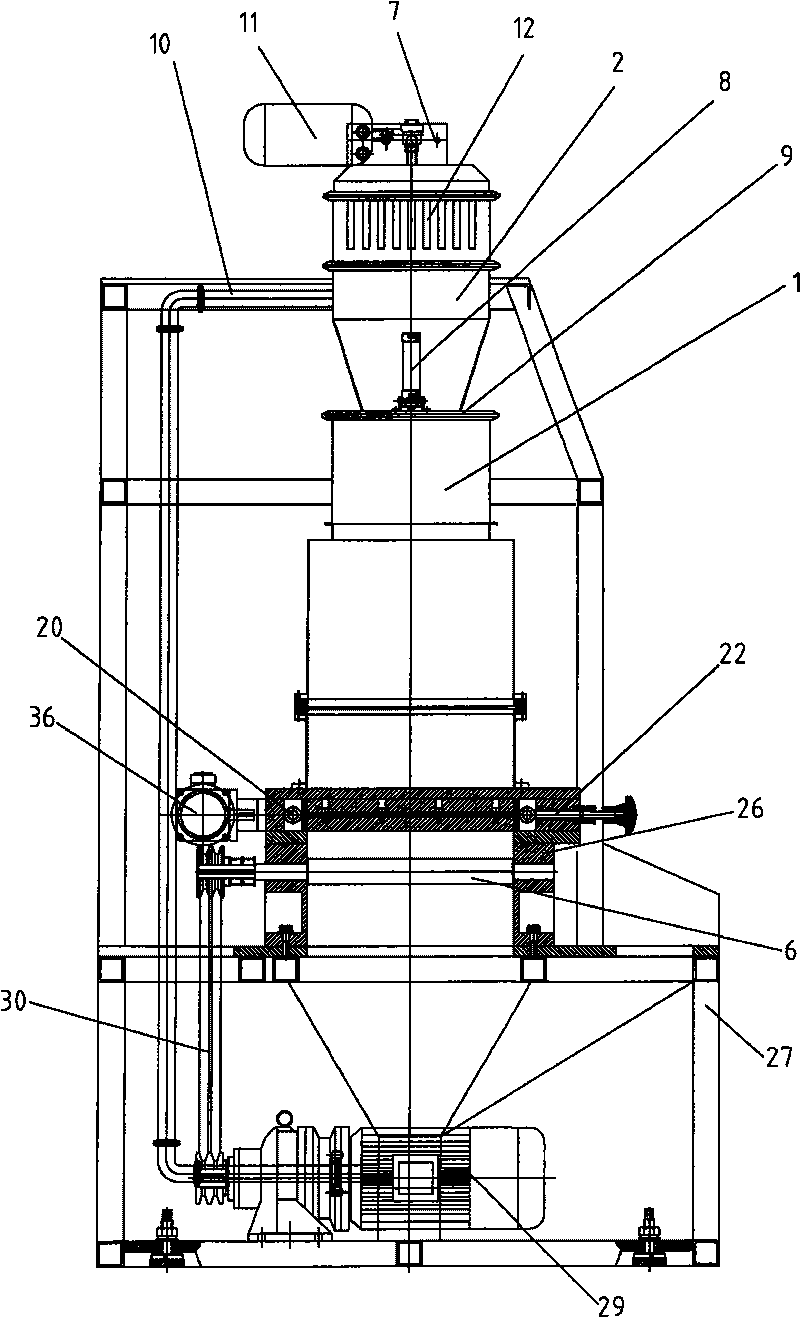

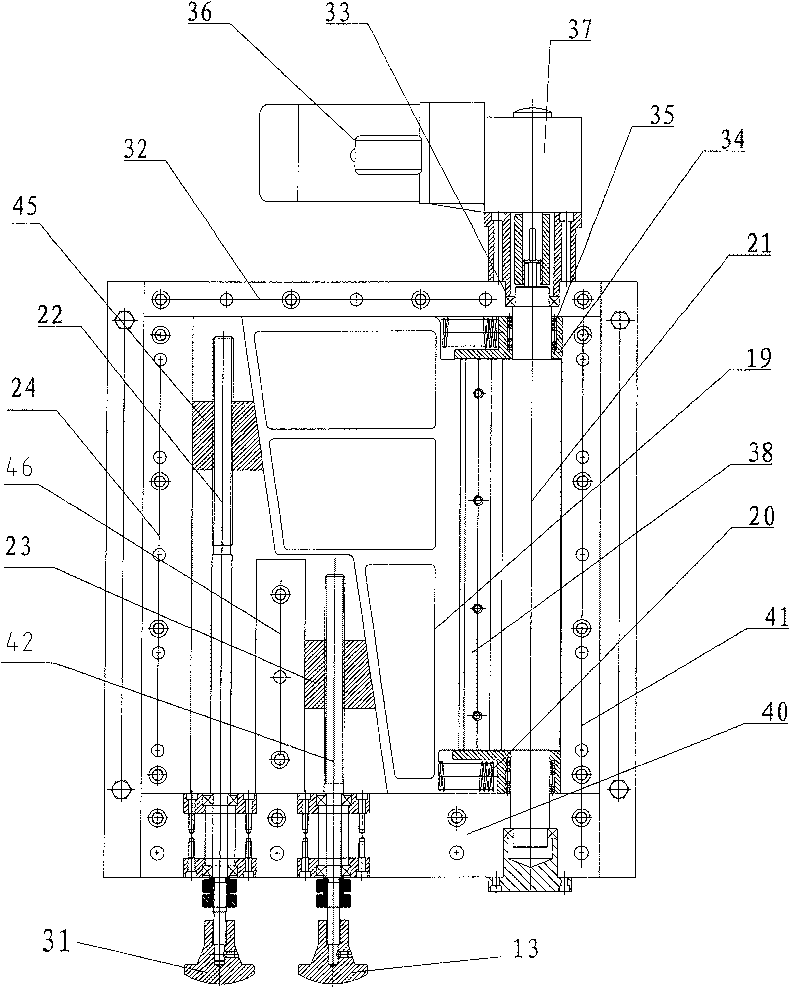

[0031] see figure 1 , figure 2 , the roller synchronous conveying device is installed on the frame 27, the rotating knife-edge powder leakage mechanism is set up above the roller synchronous conveying device, and the adjusting silo 3 is arranged on the rotating knife-edge powder leakage mechanism, and the vacuum material lifting mechanism is set on the adjusting hopper 3, A receiving hopper 4 and a receiving bin 5 are arranged below the roller synchronous conveying device; a powder flow regulating gate valve is arranged between the main hopper 1 and the adjusting bin 3 .

[0032] see Figure 7 , the roller synchronous conveying device is: the conveying roller is divided into an active conveying roller 6 and a driven conveying roller 25, which are fixed on the frame 27 by two strip roller holders 26, and are connected by a synchronous belt 28 between the conveying rollers; The frequency conversion speed regulating motor 29 is installed in the frame 27, and is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com