Photosensitive black composition and color filter

A technology of photosensitivity and composition, which is applied in the field of black matrix color filters, can solve the problems of different light-shielding properties and changes, and achieve high light-shielding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a~1d

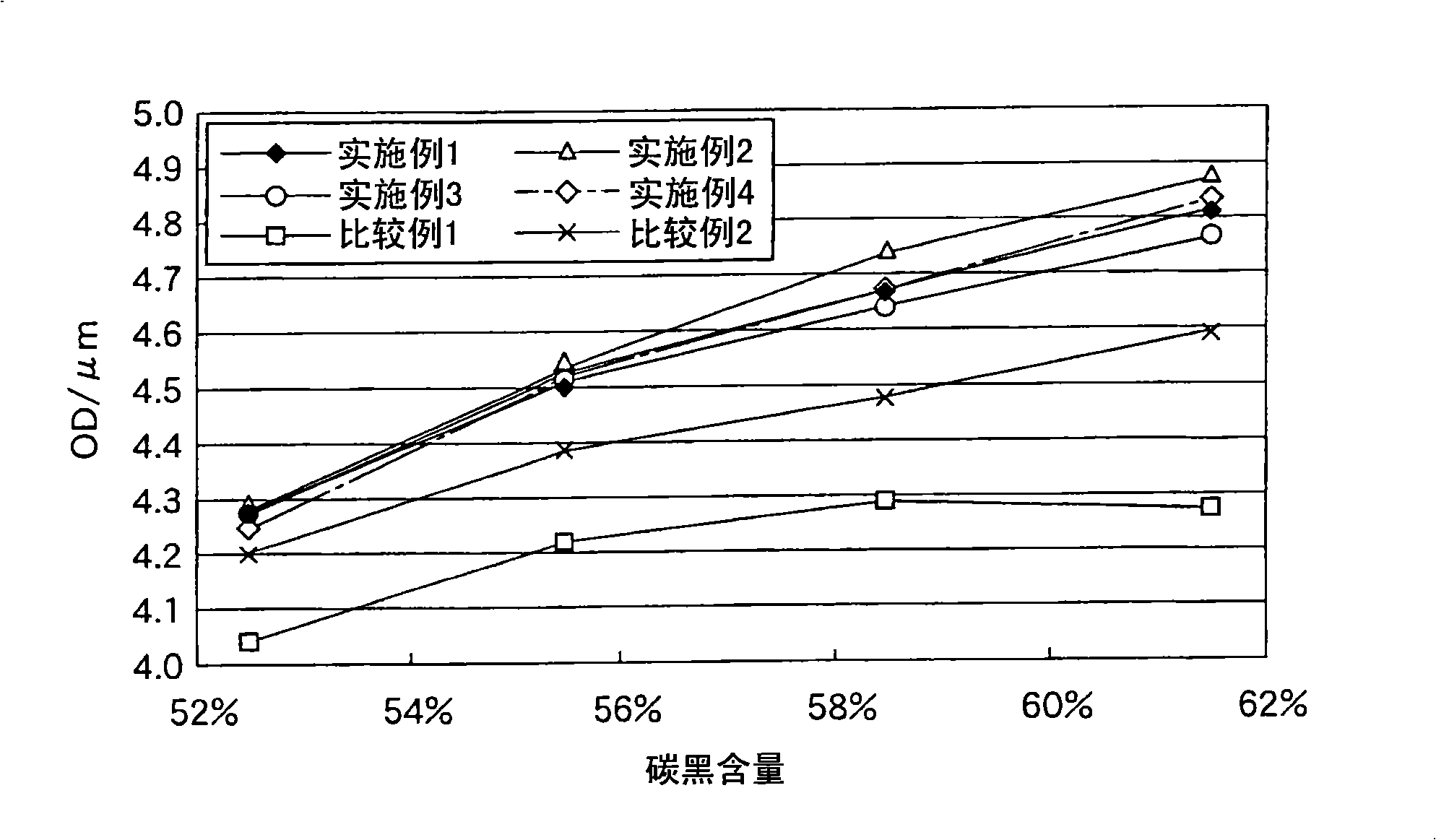

[0170] For the carbon black dispersion A, according to the compounding composition shown in Table 1, the mixture was stirred and mixed to make it uniform, and then filtered with a 2 μm filter to obtain photosensitive black compositions with different carbon black contents (embodiment 1a~ 1d).

[0171] Table 1:

[0172] Example 1a

Example 1b

Example 1c

Example 1d

Carbon black dispersion amount (wt%)

A

62.34

A

65.91

A

69.47

A

73.03

Resin solution 1

12.29

10.49

8.69

6.89

photopolymerization initiator a)

0.76

0.76

0.76

0.76

ethylenically unsaturated compound b)

2.08

1.91

1.74

1.56

solvent c)

22.53

20.94

19.35

17.76

total

100.00

100.00

100.00

100.00

Carbon black content (weight%)

52.5

55.5

58.5

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com