Underwater electrohydraulic control valve

An electro-hydraulic control valve and electromagnetic technology, which is applied in the field of solenoid valves for well control devices and solenoid valves that control pilot fluid on and off, can solve problems such as not being able to meet the high-pressure system, not being able to apply underwater, and small valve core volume, etc., to achieve Facilitate product serialization, simple structure, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

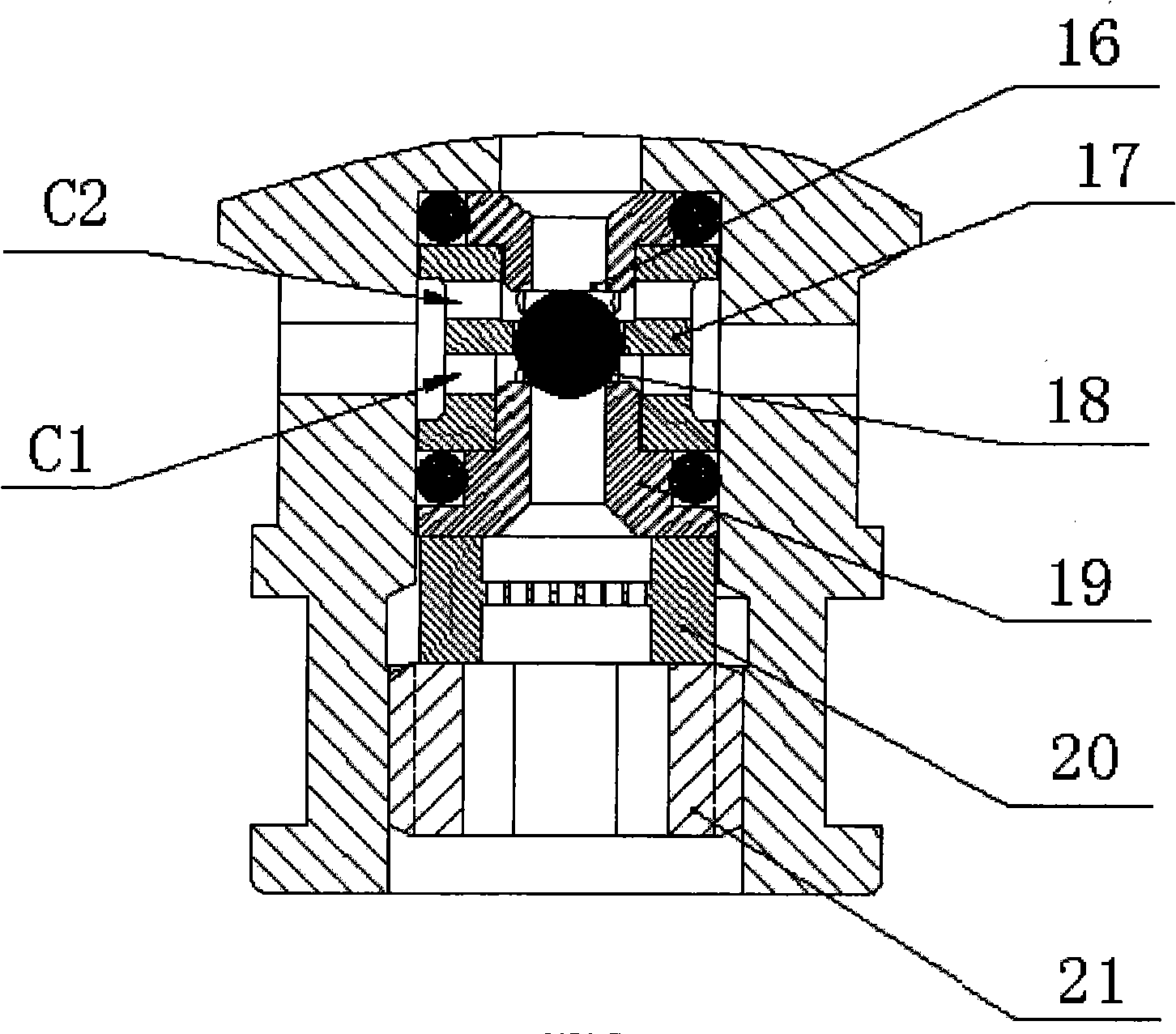

[0017] refer to figure 1 . The underwater electro-hydraulic control valve is composed of an electromagnetic part and an oil pressure end 14. The upper half is the electromagnetic part, and the lower half is the oil pressure end 14.

[0018] The electromagnetic part is mainly composed of cable plug 1, terminal board 2, shell 3, spring sleeve 4, electromagnetic coil 5, compression spring 6, iron core 7, iron core sleeve 8, wire plug 9, gland 10, screw 11, fixing screw 12 , Push rod 13 and oil pressure end 14 are made up.

[0019] One end of the cable plug 1 is inside the cylindrical shell 3, and the other end of the cable plug 1 is outside the shell 3. There is a sealing ring on the cylindrical contact surface and the contact plane between the cable plug 1 and the shell 3, and the sealing ring is in the Seawater can be prevented from entering the shell 3 . A terminal board 2 is arranged in the cable plug 1, and some power amplifier circuits are housed on the terminal board 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com