Spring self-switching type Y-shaped joint

A self-switching, head-end technology, applied in the fields of production fluids, drilling equipment, measurement, etc., can solve the problems of reducing the normal production time of oil wells and occupying operation time, so as to reduce the workload of operation, save operation costs, and meet production requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

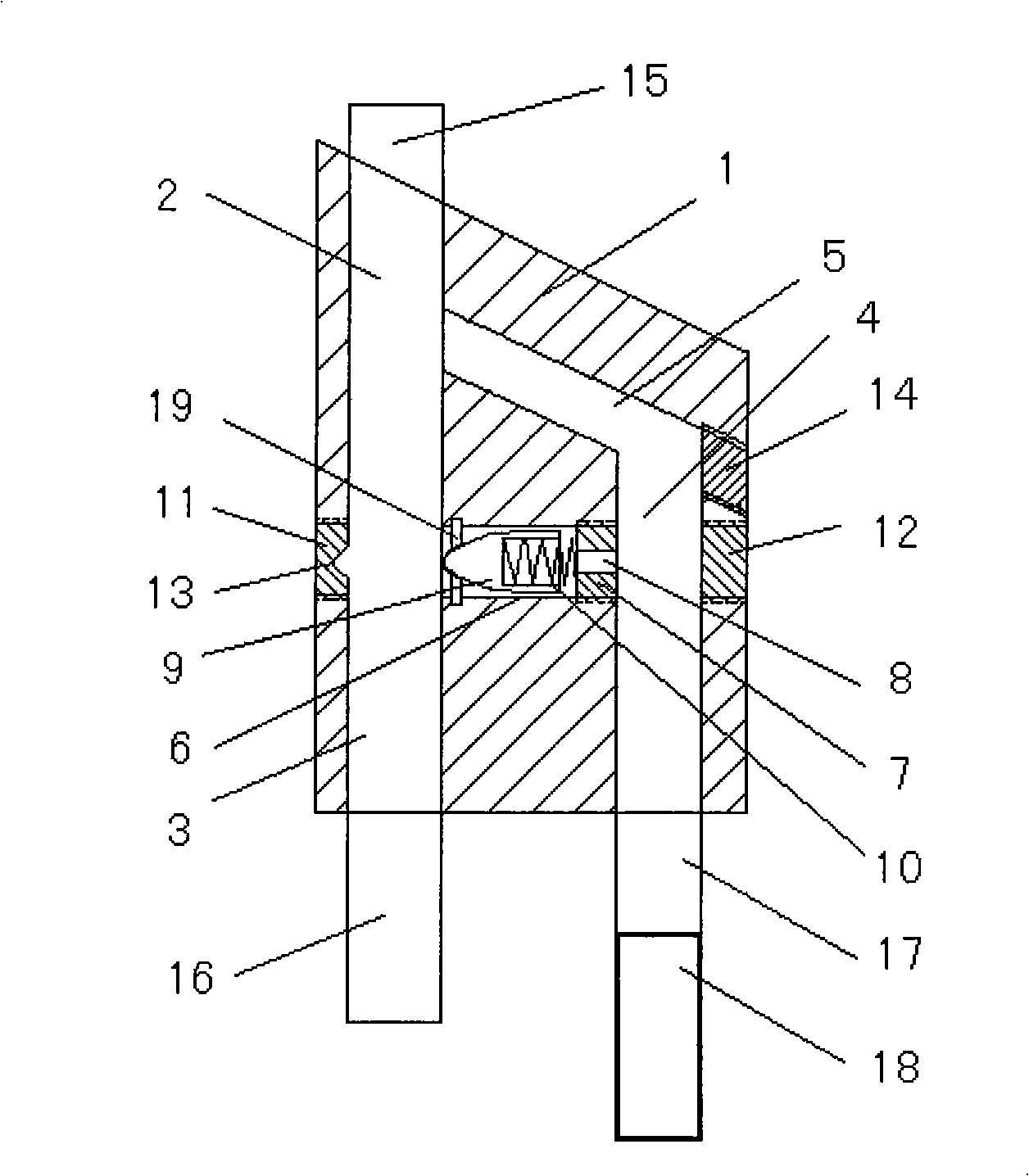

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

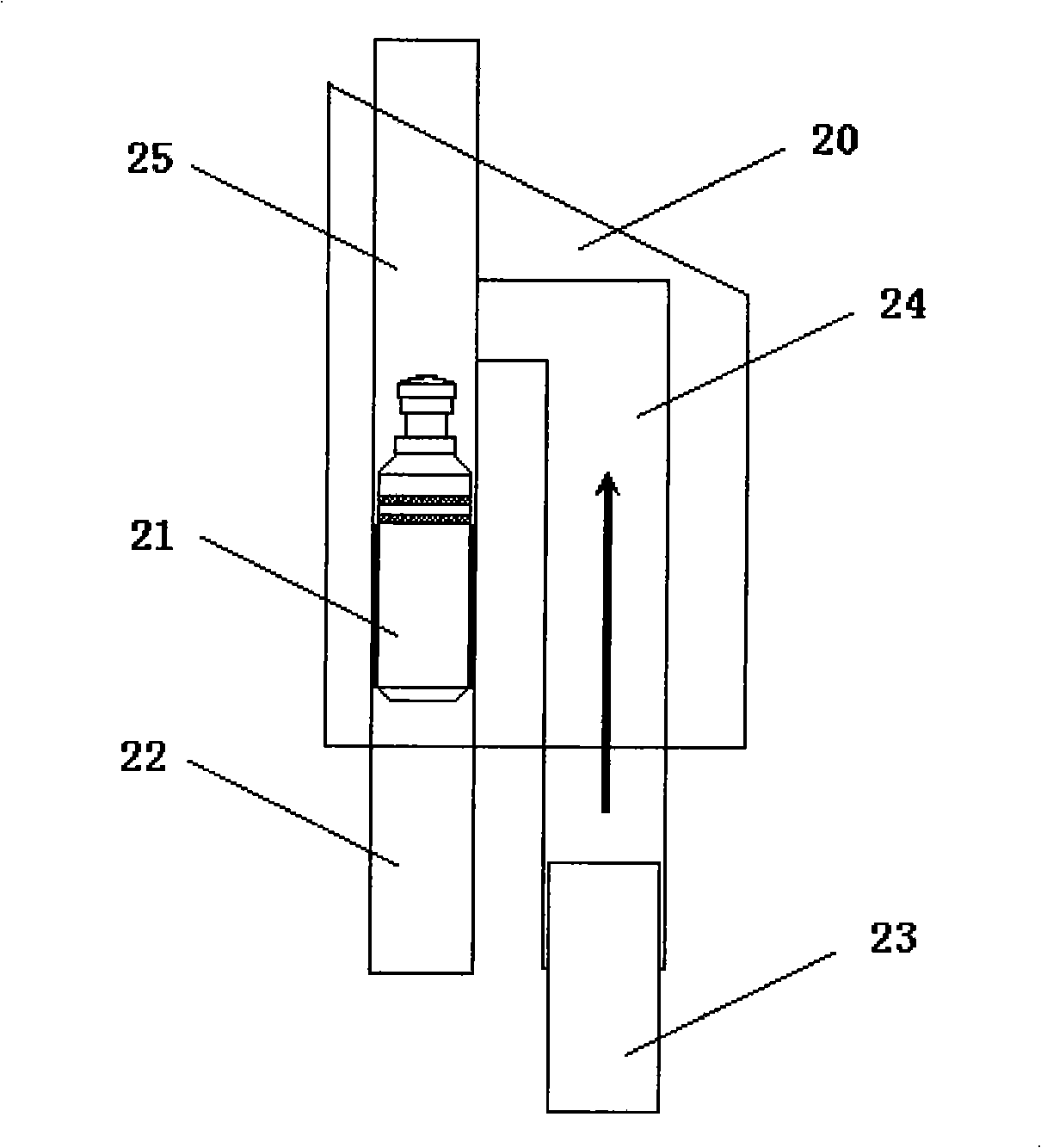

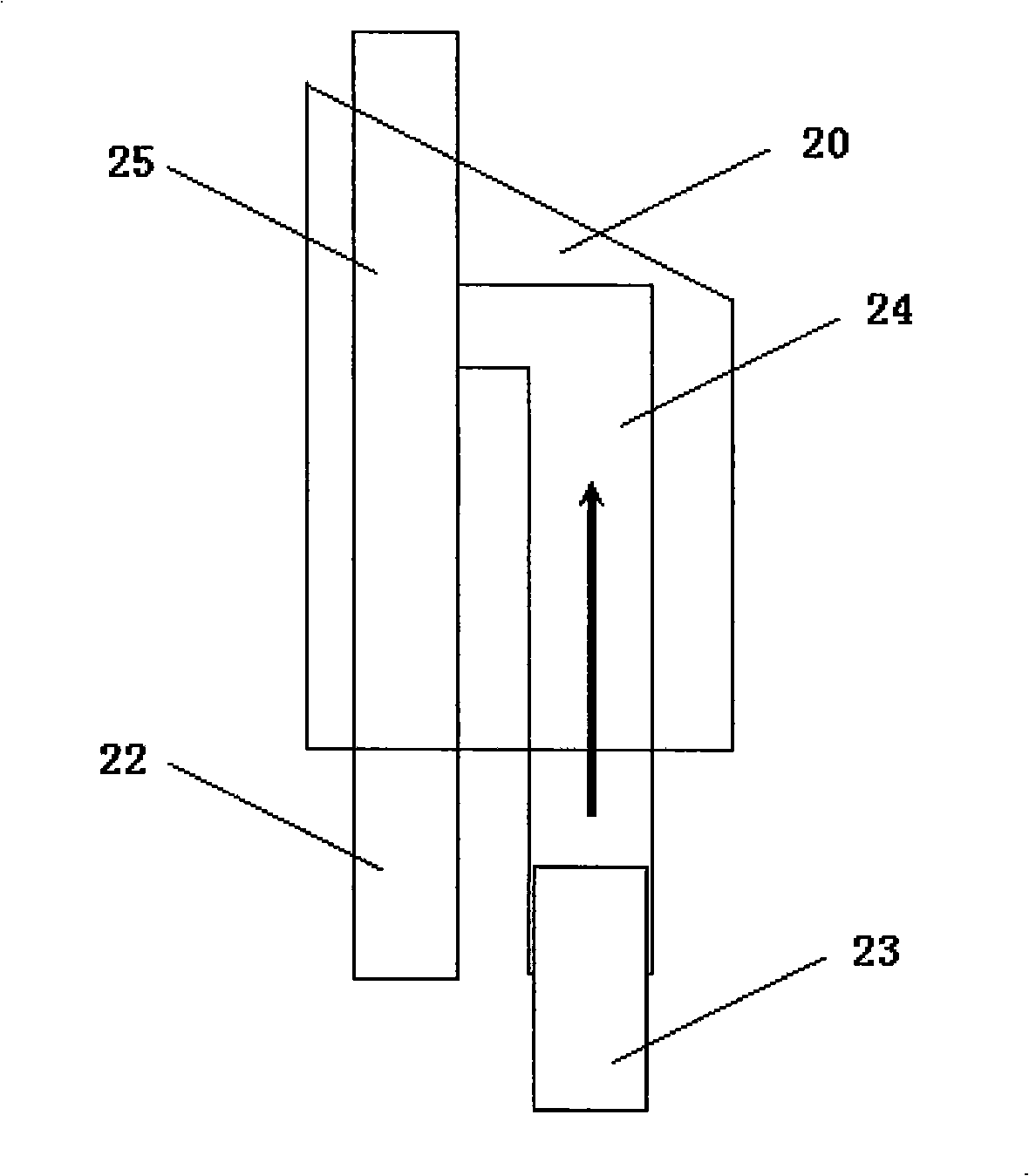

[0016] Such as image 3 As shown, the present invention includes a joint body 1, one side of the joint body 1 is provided with a production channel 2 and a downhole testing channel 3 communicating with the production channel 2, and the other side of the joint body 1 is provided with an electric pump oil pumping channel 4 , The upper part of the electric pump oil suction channel 4 is provided with an inclined oil suction channel 5 communicating with the production channel 2 . A slideway hole 6 is horizontally set between the test passage 3 and the electric pump oil passage 4, and an end cover 7 is screwed into the slideway hole 6 on the side close to the electric pump oil passage 4. Pressure hole 8. A sealing slider 9 with its head facing the test channel 3 is arranged in the slideway hole 6 . Such as Figure 4 As shown, the head of the sealing sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com