Door and window system with wood surface film and manufacture and assembly method thereof

A wood surface and film coating technology, which is applied to door/window accessories, crafts for producing decorative surface effects, windows/doors, etc., can solve problems affecting the environmental protection of doors and windows, achieve good sealing, enhance environmental protection, The effect of high structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

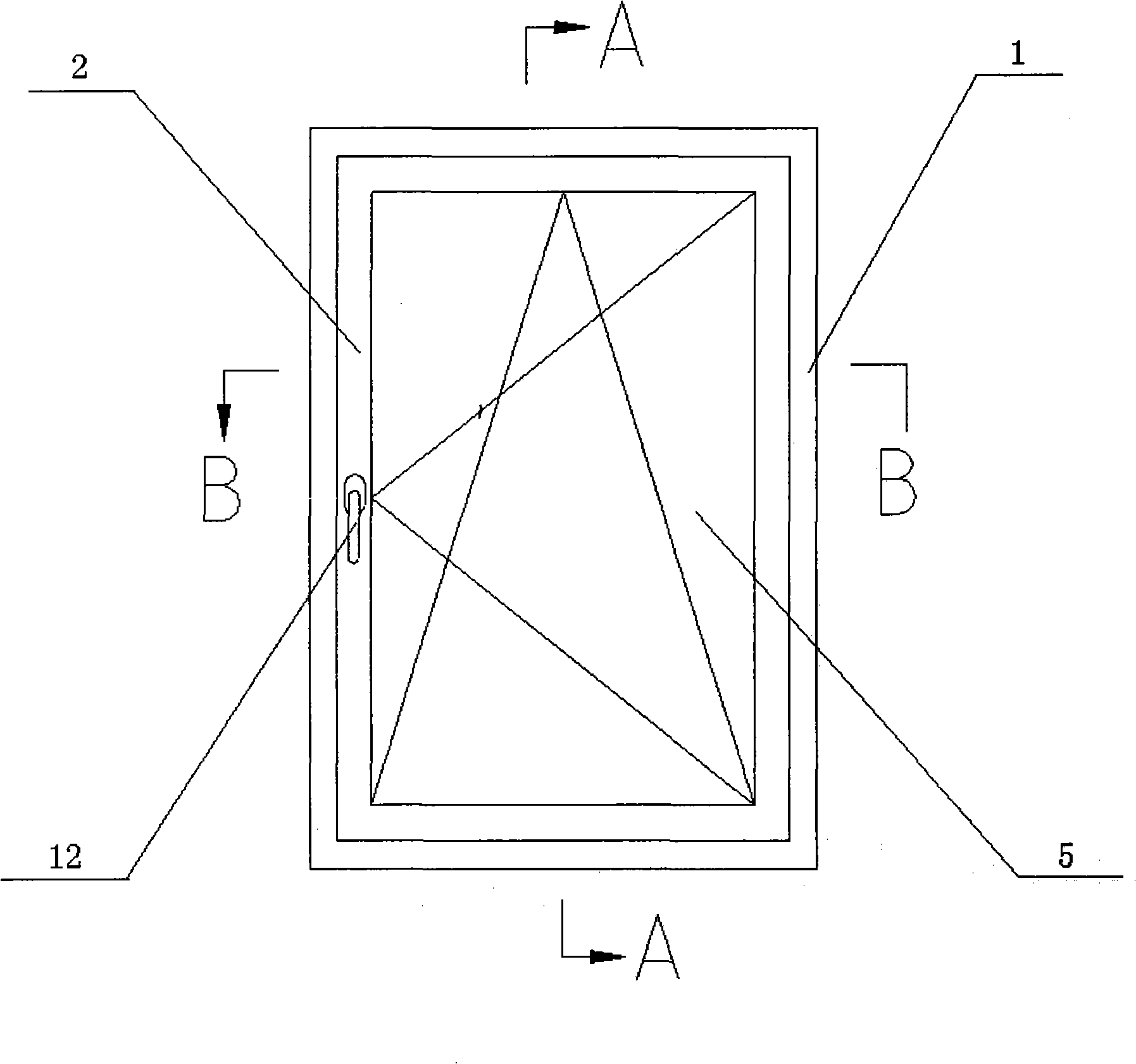

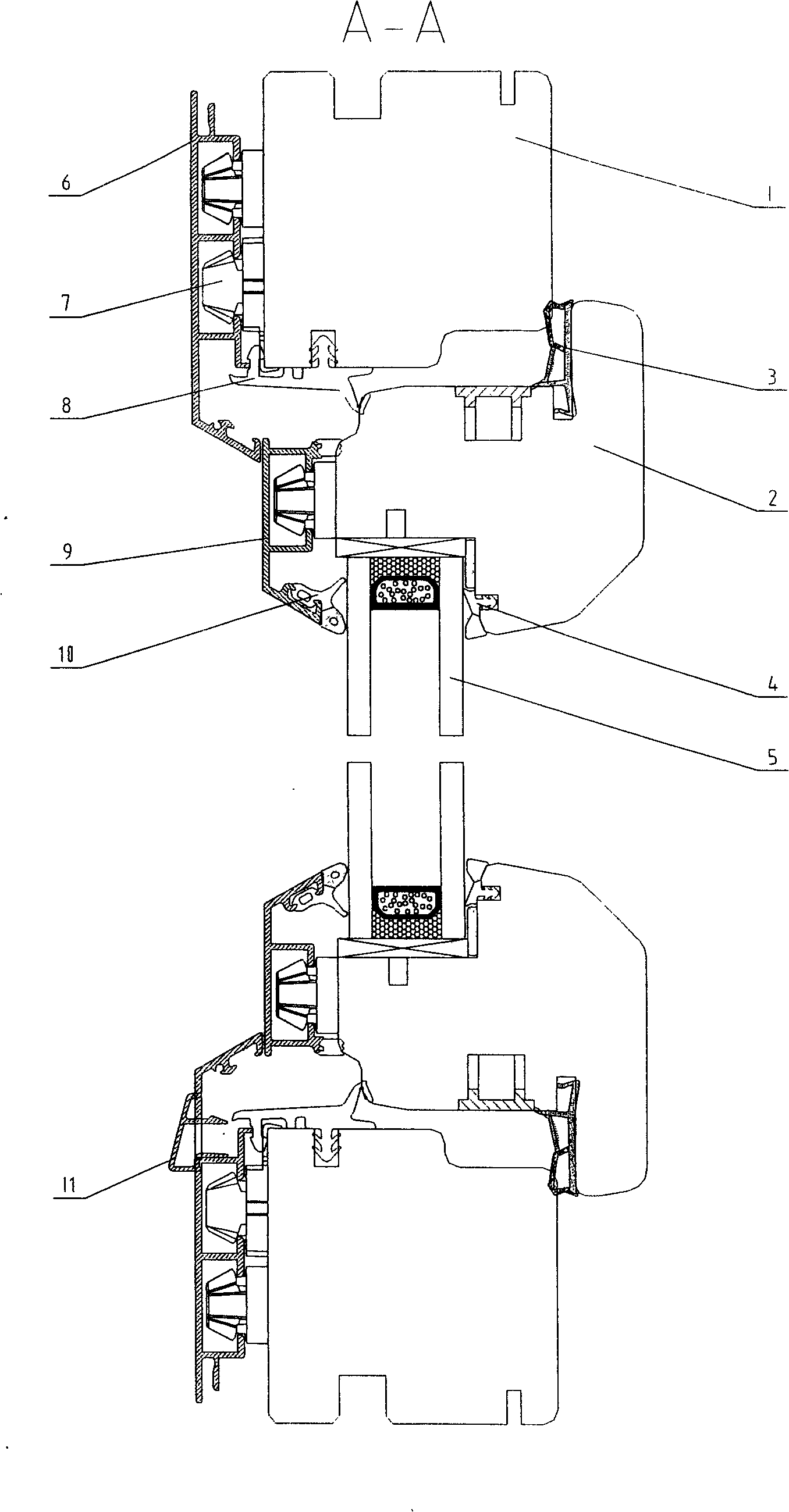

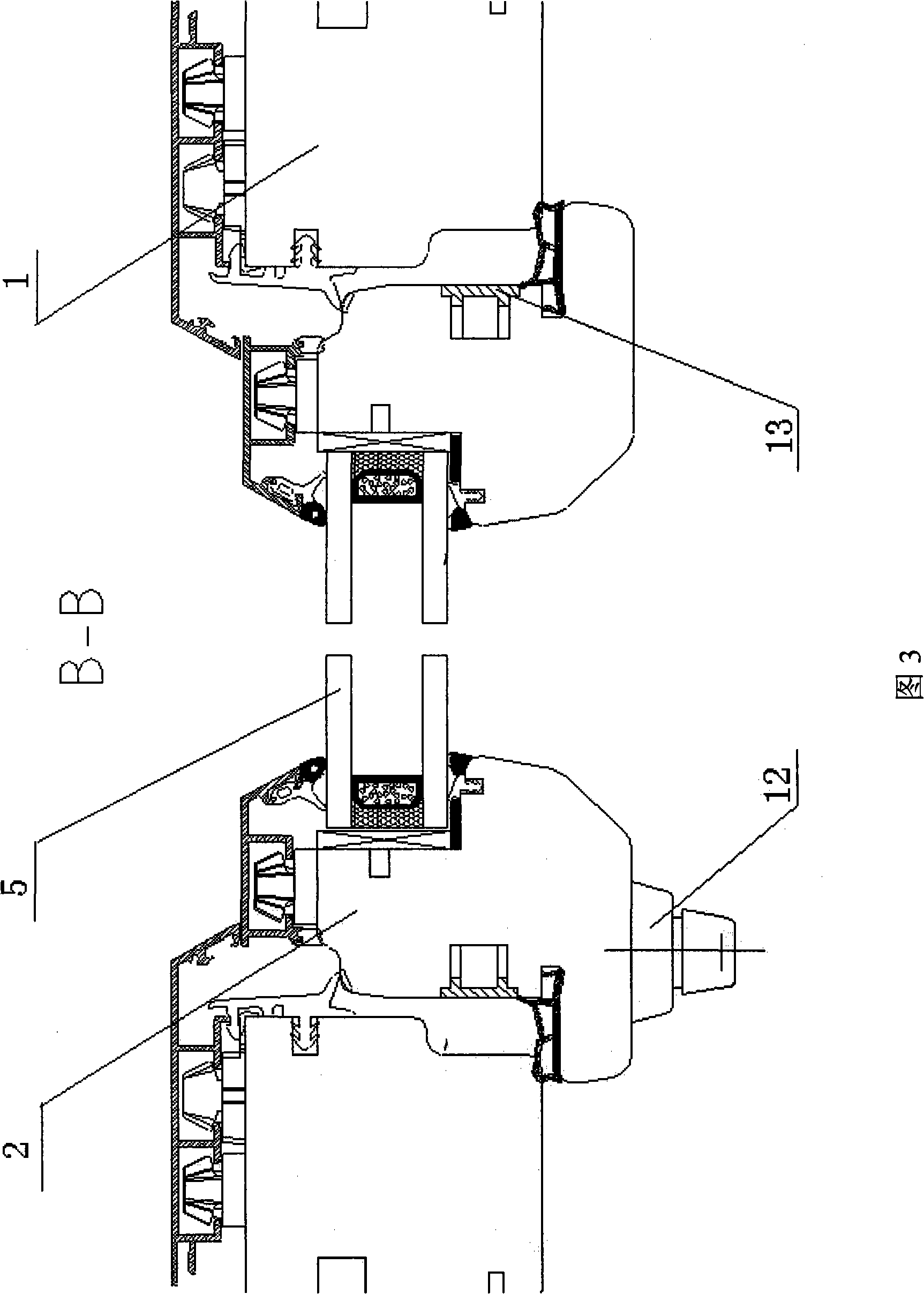

[0028] Embodiment 1: a kind of door and window system (see figure 1 -3), including wooden window frame 1, wooden sash 2, insulating glass 5 and window handle 12 (see figure 1 ), it is characterized in that the surface of said wooden window frame 1 and wooden sash 2 has a veneer film; the system composition also includes: I sealing strip 3, II sealing strip 4, III sealing strip 8, IV sealing strip 10, I aluminum Quality shell 6, II aluminum shell 9, III aluminum shell 11, related connection pendant 7 and the frame sash combination hardware system 13 of the window; said I sealing strip 3 is located between the wooden window frame 1 and the wooden sash 2, and Around the window sash, it is embedded in the groove on the side of the wooden window sash 2 away from the hollow glass 5 (see figure 2 ); said II sealing strip 4 and insulating glass 5 are all located on the wooden sash 2, and II sealing strip 4 surrounds the wooden sash 2 and is embedded in the groove on the side of the ...

Embodiment 2

[0041] Embodiment 2: a kind of door and window system (see figure 1 -3), including wooden window frame 1, wooden sash 2, insulating glass 5 and window handle 12 (see figure 1 ), it is characterized in that the surface of said wooden window frame 1, wooden sash 2 has paper skin film; The system composition also includes: I sealing strip 3, II sealing strip 4, III sealing strip 8, IV sealing strip 10, I Aluminum casing 6, II aluminum casing 9, III aluminum casing 11, related connection pendant 7 and window frame sash combination hardware system 13; said I sealing strip 3 is located between wooden window frame 1 and wooden sash 2, And surround the window sash and be embedded in the groove on the side of the wooden window sash 2 away from the hollow glass 5 (see figure 2 ); said II sealing strip 4 and insulating glass 5 are all located on the wooden sash 2, and II sealing strip 4 surrounds the wooden sash 2 and is embedded in the groove on the side of the wooden sash 2, and is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com