Screen grader having untwining function

A screening machine and defrosting machine technology, applied in the field of screening machines, can solve the problems of waste of resources, waste of energy, no defrosting function, etc., and achieve the effects of saving energy, reducing energy consumption for deflating, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

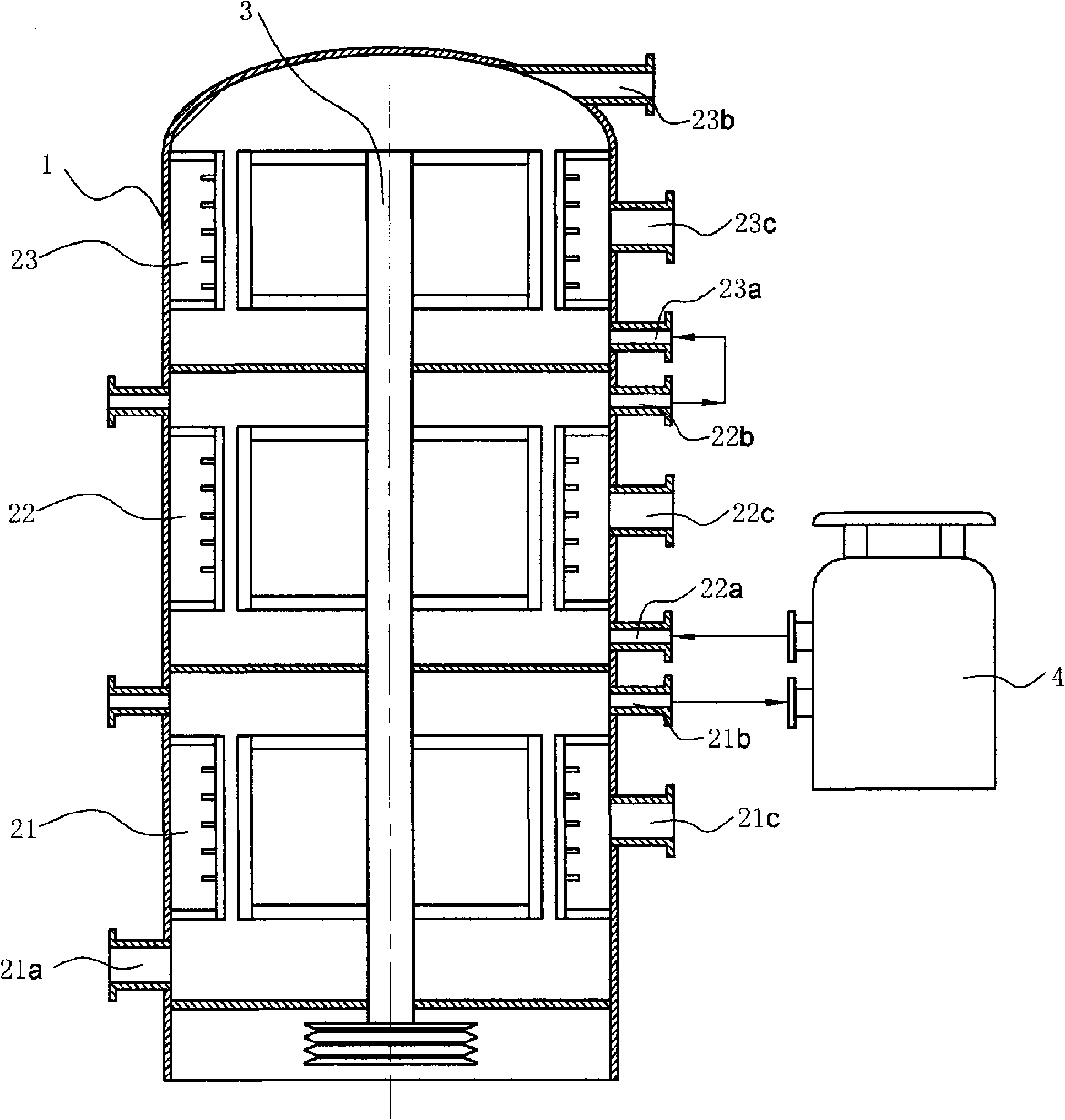

[0014] Embodiment one: if figure 1 As shown, the screening machine with decompression function includes a casing 1, and the first pressure screen unit 21, the second pressure screen unit 22 and the third pressure screen unit 23 are connected in series in the casing 1, and the The first pressure screen unit 21, the second pressure screen unit 22 and the third pressure screen unit 23 have a common rotor shaft 3 that drives its rotor to rotate; the first pressure screen unit 21 is provided with a pulp inlet 21a, a well A pulp outlet 21c, a residual pulp outlet 21b, the second pressure screen unit 22 is provided with a pulp inlet 22a, a good pulp outlet 22c, and a residual pulp outlet 22b, and the third pressure screen unit 23 is provided with a pulp inlet Port 23a, good pulp outlet 23c, residual pulp outlet 23b, a pulp disintegrator 4 is installed between the residual pulp outlet 21b of the first pressure screen unit 21 and the pulp inlet 22a of the second pressure screen unit 22...

Embodiment 2

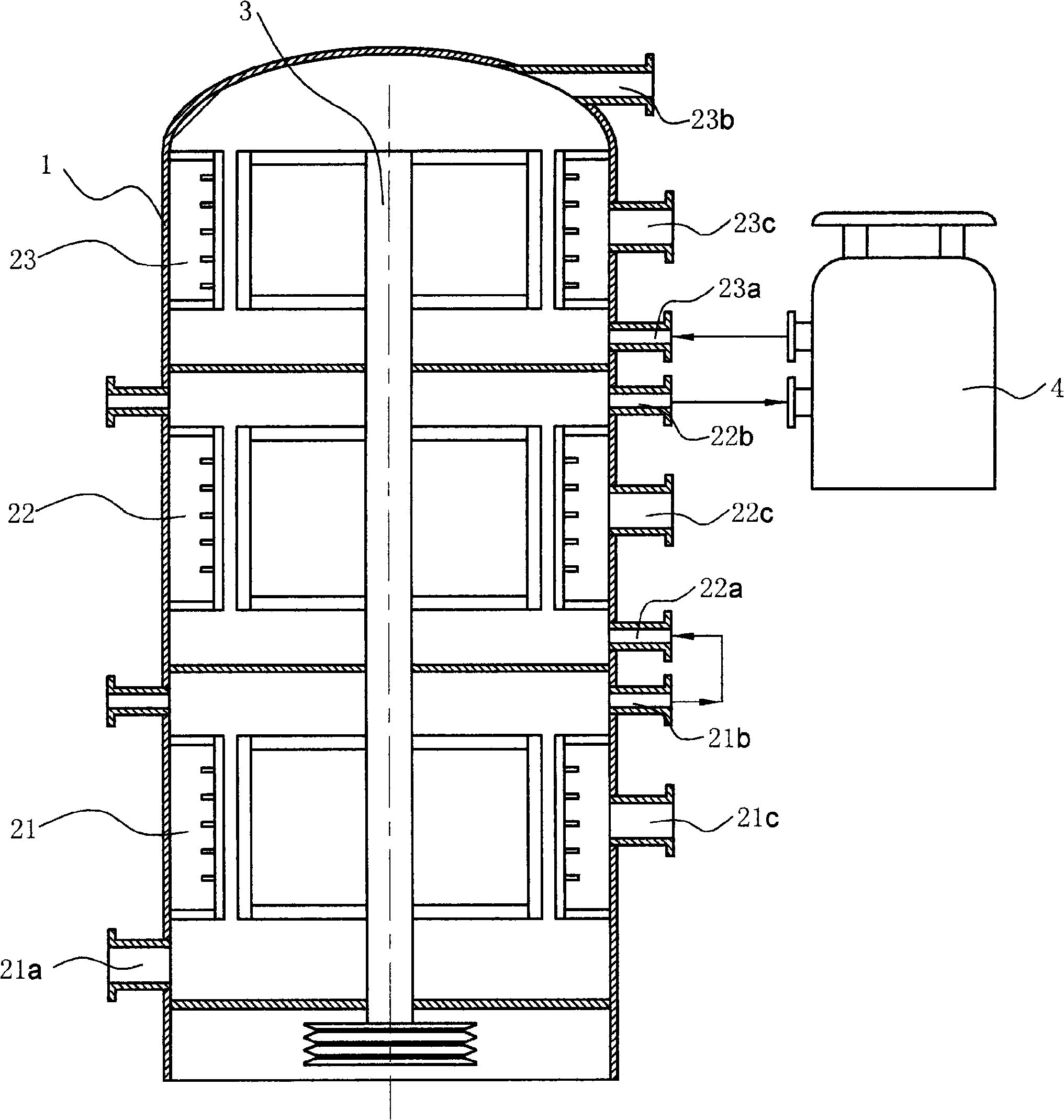

[0015] Embodiment two: if figure 2 As shown, the structure is basically the same as that of Embodiment 1, except that a pulp disintegrator 4 is installed between the residual pulp outlet 21b of the first pressure screen unit 21 and the pulp inlet 22a of the second pressure screen unit 22 , the slurry outlet 22b of the second pressure screen unit 22 is connected with the slurry inlet 23a of the third pressure screen unit 23 .

Embodiment 3

[0016] Embodiment three: as image 3 As shown, the structure is basically the same as that of Embodiment 1, except that a pulp disintegrator 4 is installed between the residual pulp outlet 22b of the second pressure screen unit 22 and the pulp inlet 23a of the third pressure screen unit 23 , the slurry outlet 21b of the first pressure screen unit 21 is connected with the slurry inlet 22a of the second pressure screen unit 22 .

[0017] Of course, we can directly make the partition between the second pressure screen unit 22 and the third pressure screen unit 23 in Embodiment two or the first pressure screen unit 21 and the second pressure screen unit 21 in Embodiment three for the convenience of manufacture. The dividing plate between the pressure screen units 22 is removed and just connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com