PVC coating high strength polyester filament yarn leno lining and production method thereof

A technology of polyester filament and production method, applied in the direction of leno fabric, leno fabric, fabric, etc., can solve the problems of application of leno fabric, etc., and achieve the effect of high warp and weft density and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

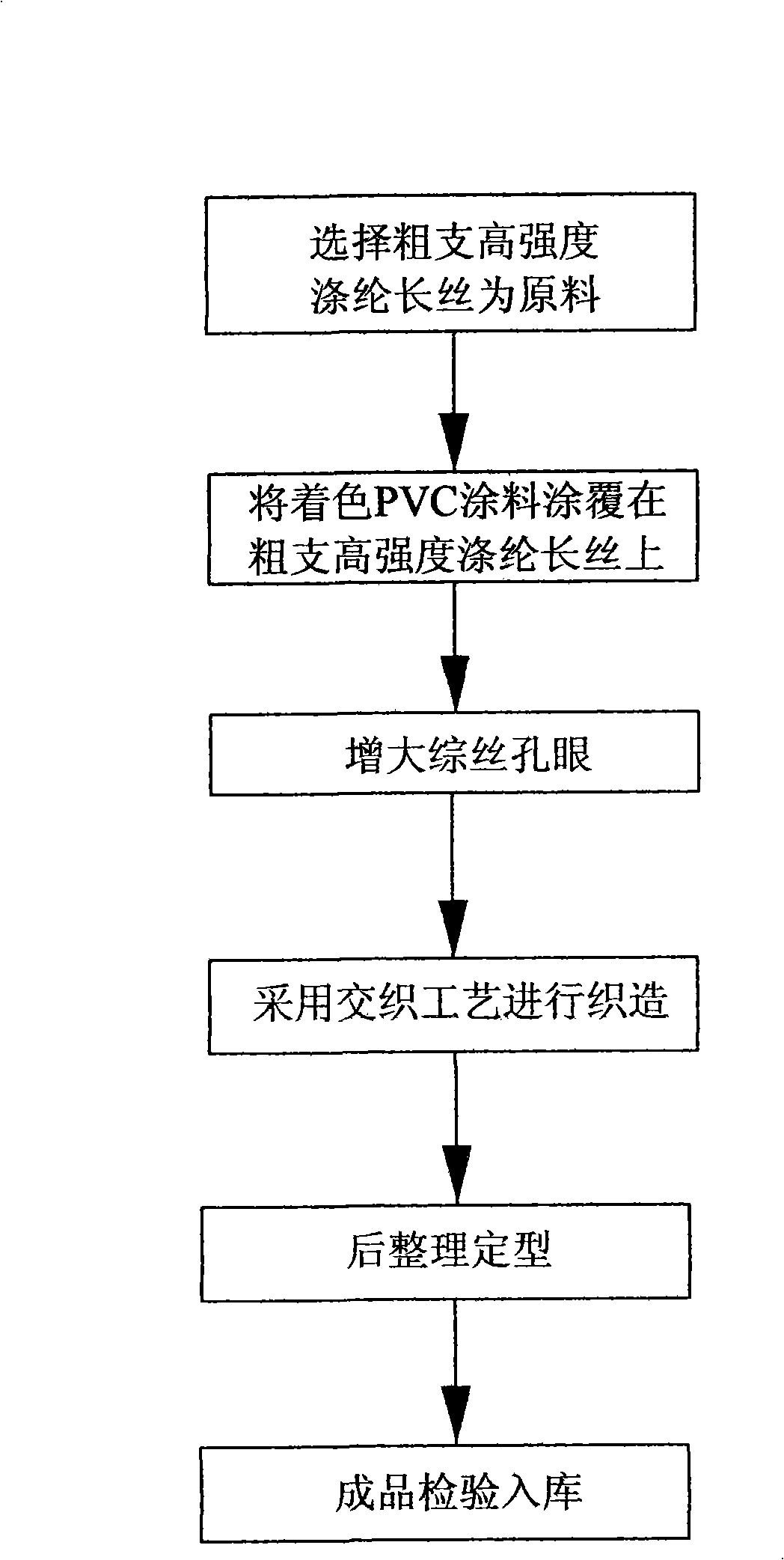

[0019] Such as figure 1 As shown, the production method flow process of the leno fabric of the present invention includes selection of raw materials—color matching, material making—PVC coating—warping—twisted heddle weaving—drafting—weaving—after finishing— - Finished product inspection, details are as follows:

[0020] 1. Raw material selection: The leno fabric is made of coarse-count high-strength polyester filament, among which:

[0021] The ground warp adopts 50~1100D high-strength industrial polyester filament

[0022] Twisted warp adopts 1100D high-strength industrial polyester filament and PVC coated wire

[0023] The weft yarn is made of 1100D high-strength industrial polyester filament and PVC coated yarn

[0024] 2. PVC coating

[0025] The environmentally friendly paint and PVC material are mixed by a mixer, the PVC material is colored by a color matching system, and it is made into PVC masterbatches of various colors by a granulator. PVC masterbatch and thick ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com