Expansion type fireproofing glue strip for construction

A fireproof rubber strip, intumescent technology, used in adhesives, film/sheet adhesives, other chemical processes, etc. Flexibility and the effect of facilitating construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

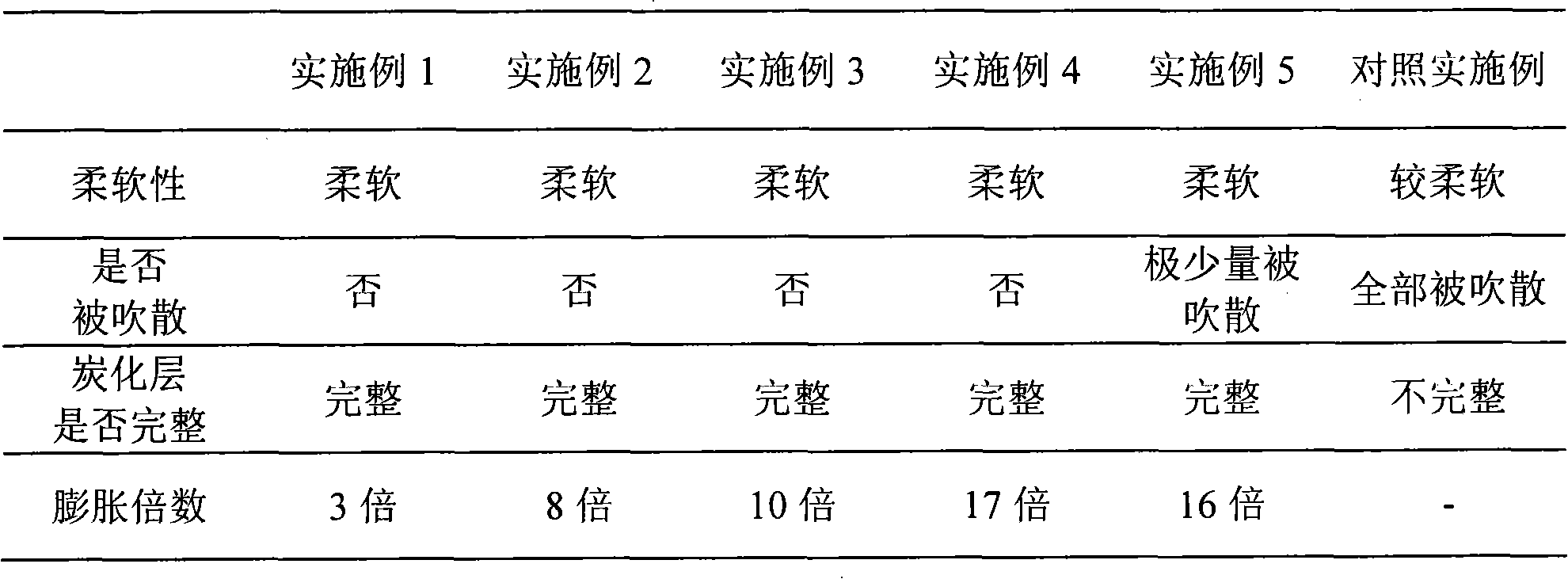

Examples

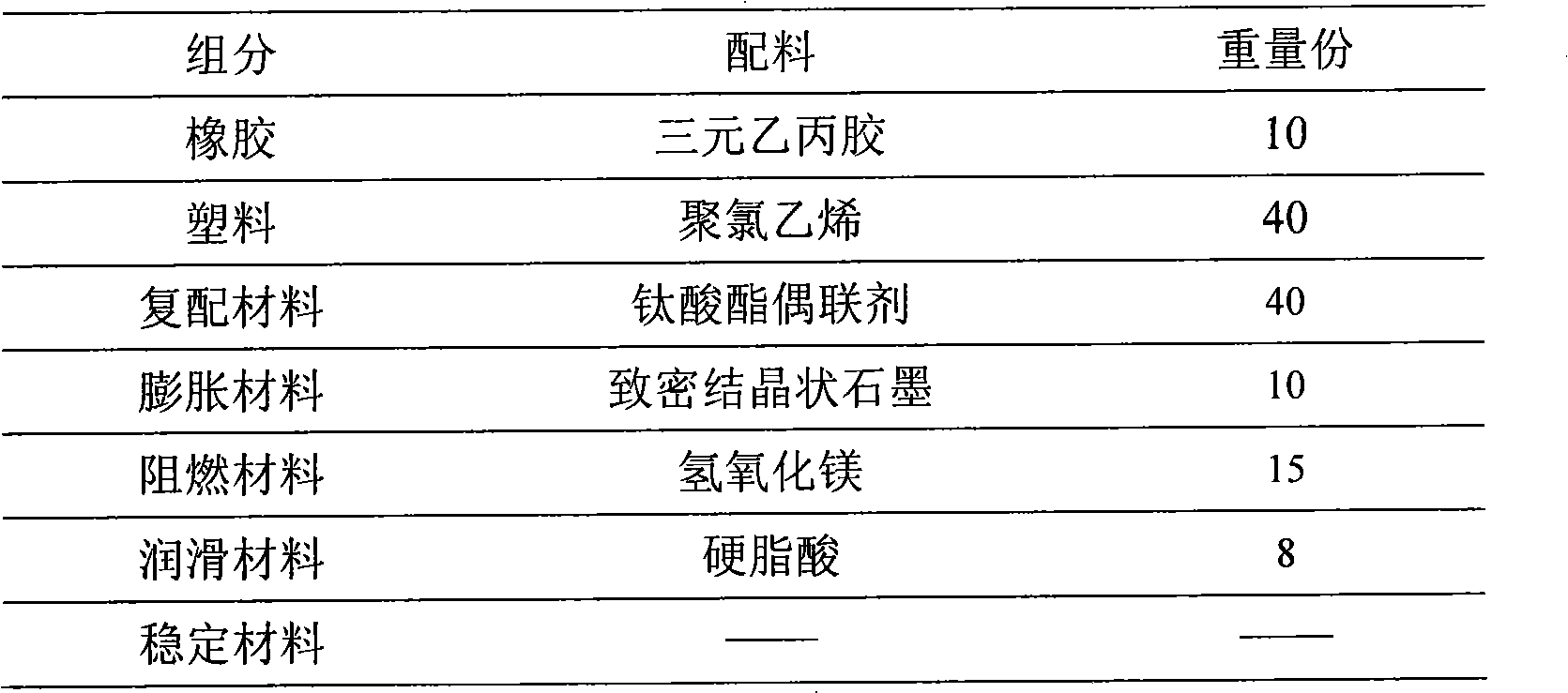

Embodiment 1

[0040] Material Proportion Table (Table 2)

[0041]

[0042] Preparation method: Take each raw material according to the material ratio in Table 2, put it on a dry powder mixer and mix it at high speed for 2 minutes, after discharging, transfer it to a twin-screw extruder for extrusion molding. The temperature of the heating chamber of the twin-screw extruder is 90-180 degrees Celsius. The cross-sectional size of the extrusion die is 3.0mm×5.0mm, or the shape and size of the extrusion die can be changed according to the requirements of actual use.

Embodiment 2

[0044] Material Proportion Table (Table 3)

[0045]

[0046] Preparation method: with example 1.

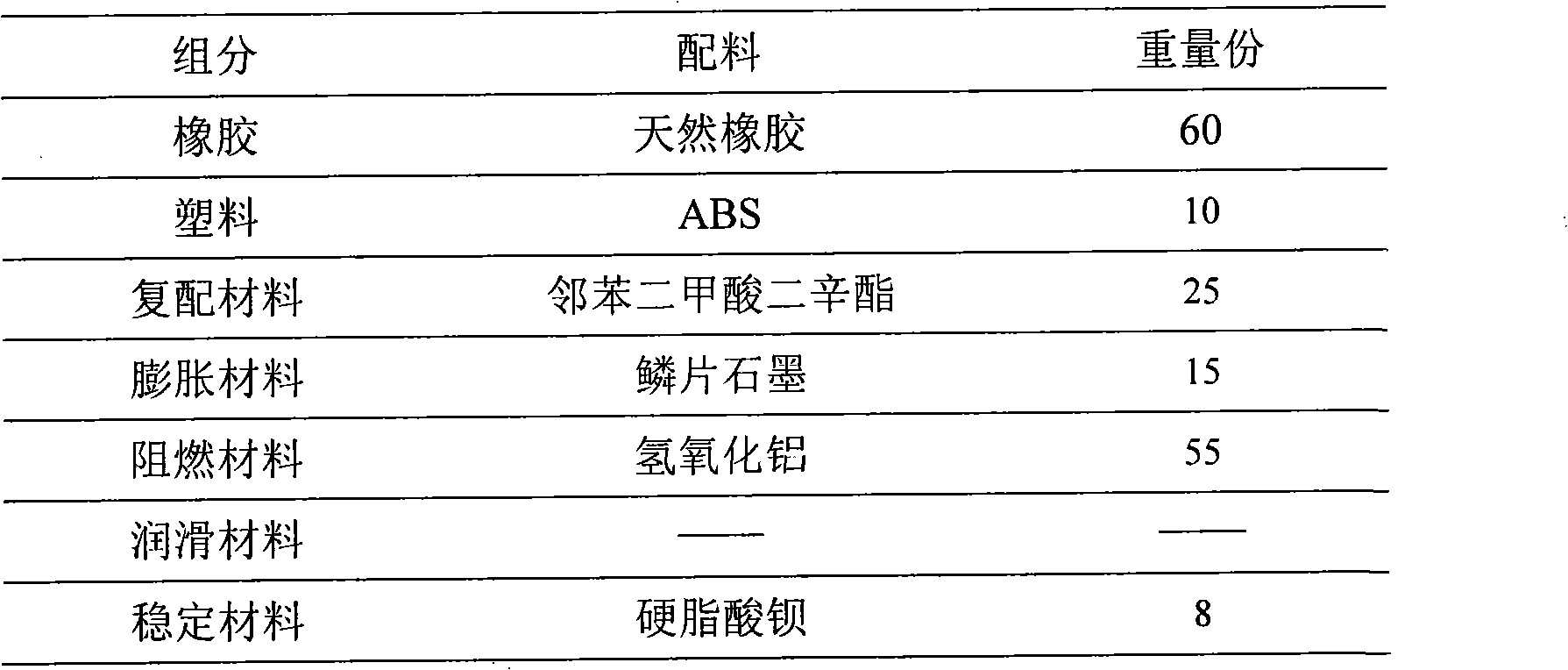

Embodiment 3

[0048] Material Proportion Table (Table 4)

[0049]

[0050] Preparation method: with example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com