Method for improving ethylene apparatus quench oil tower bottom temperature

A technology of tower bottom temperature and quenching oil, which is applied in the fields of hydrocarbon cracking, organic chemistry, etc., can solve problems such as poor heat recovery, increased steam consumption, and increased operating costs of the device, achieving huge economic benefits, saving funds, and significantly The effect of social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

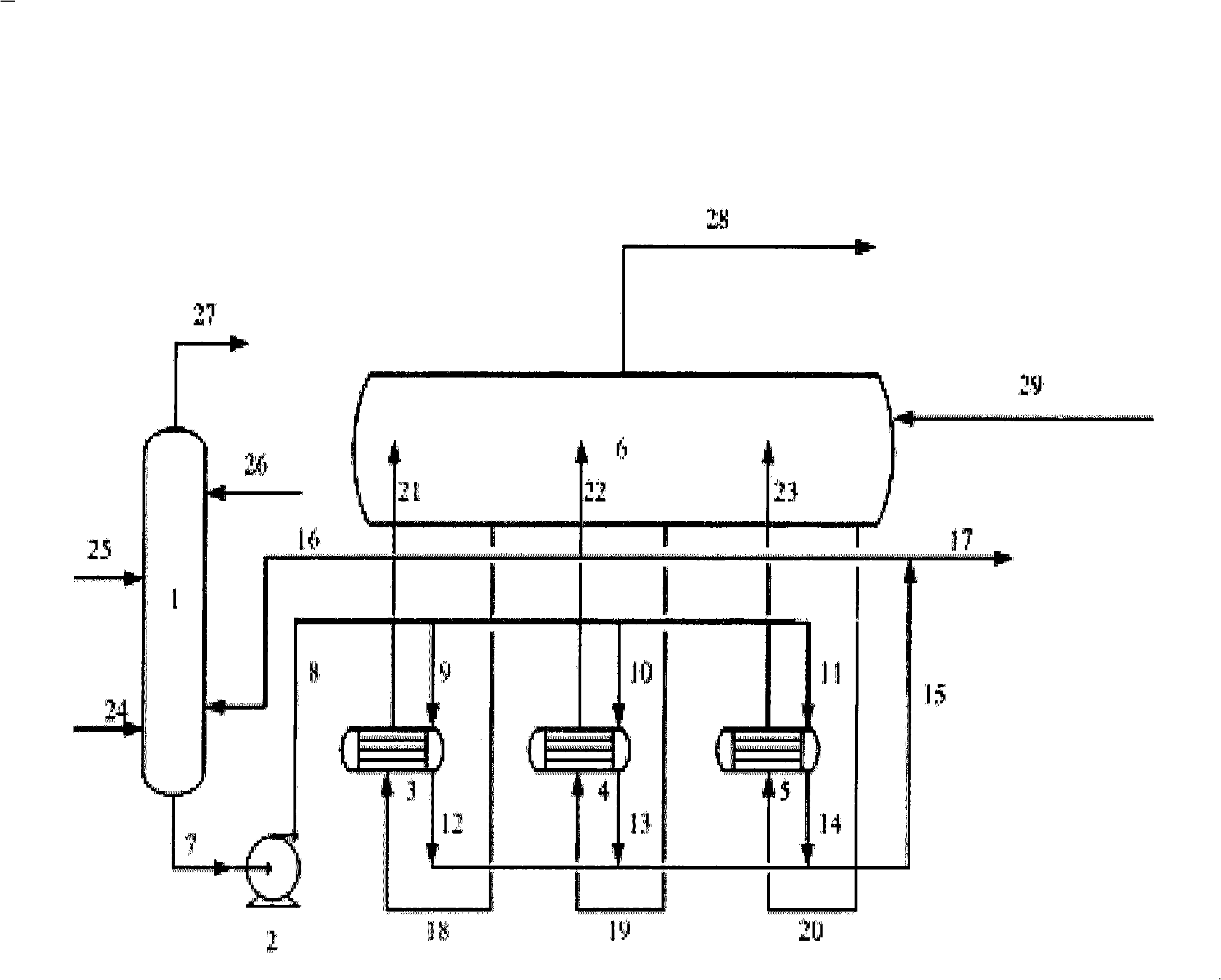

Method used

Image

Examples

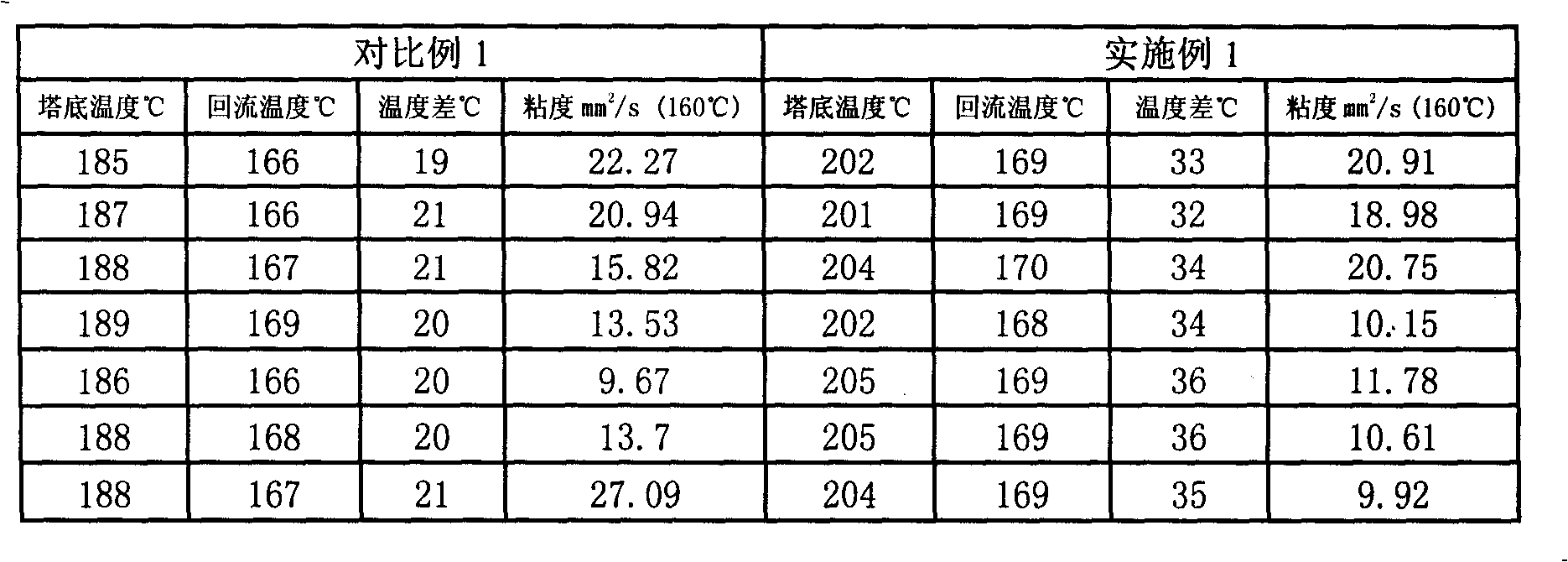

Embodiment 1

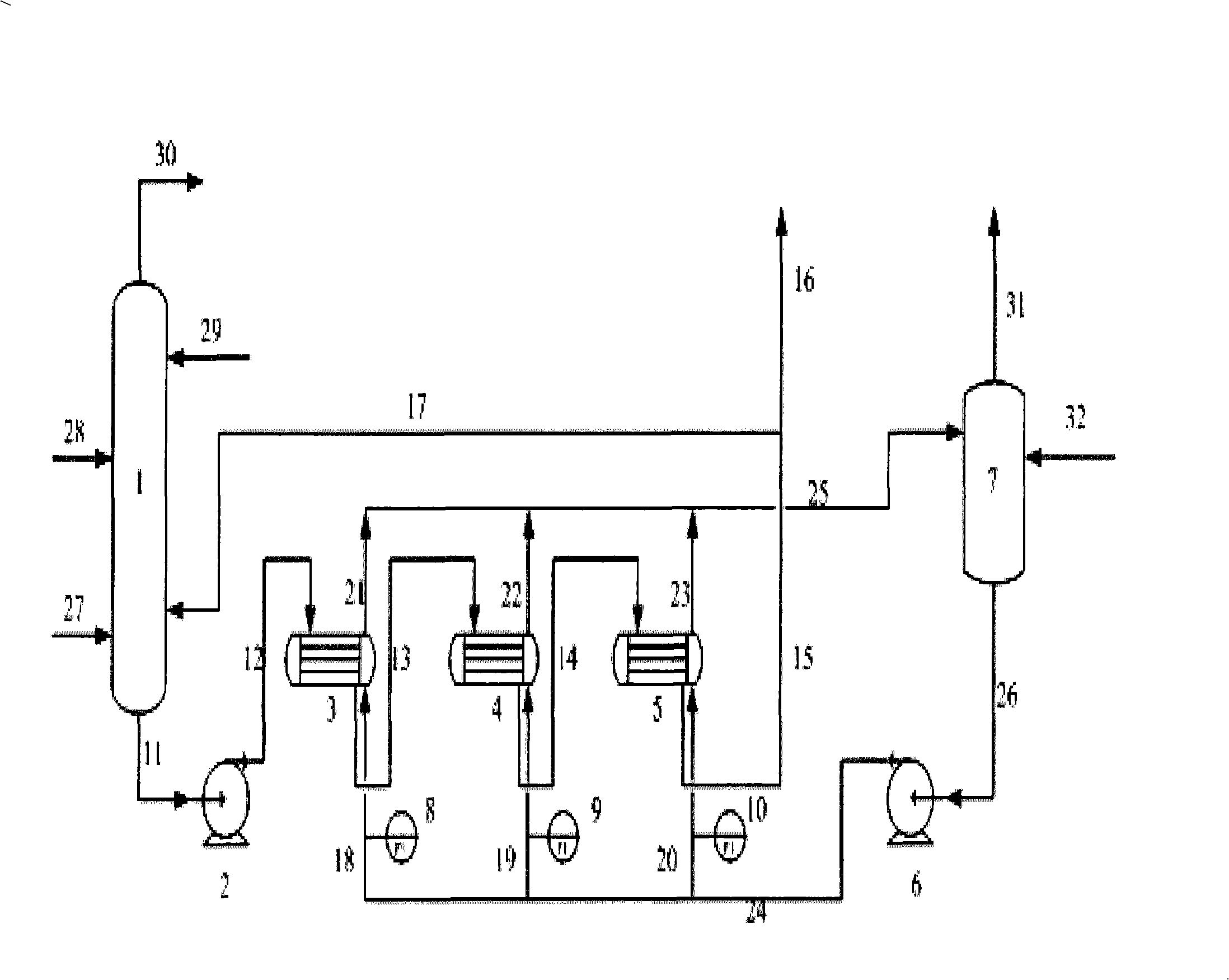

[0033] Taking the ethylene plant with an annual production capacity of 300,000 tons as an example, the quench oil cooling system shown in Figure 2 is adopted. The main equipment includes oil washing tower 1; quenching oil circulation pump 2; quenching oil heat exchangers 3, 4, 5; process water circulation pump 6; vapor / liquid separation tank 7; flow meters 8, 9, 10 and corresponding connected pipelines. And the number of groups of quench oil heat exchangers is designed as 3 groups.

[0034] The process flow is as follows:

[0035] The pyrolysis gas from the outlet of the cracking furnace is sent to the bottom of the oil washing tower 1 through the pipeline 27 after preliminary cooling, and is cooled by three streams of reflux at 27, 28, and 29. The heaviest quenching oil component in the material condenses to the bottom of the tower to form quenching oil. The oil enters the quenching oil circulation pump 2 through the pipeline 11 to boost the pressure, and is sent to the quench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com