Intelligent plate-supplying combined equipment for aluminum plastic bottle cap production line

A technology that combines equipment and production lines, applied in other manufacturing equipment/tools, general control systems, instruments, etc., to solve problems such as low production efficiency, personal injury and disability accidents, and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

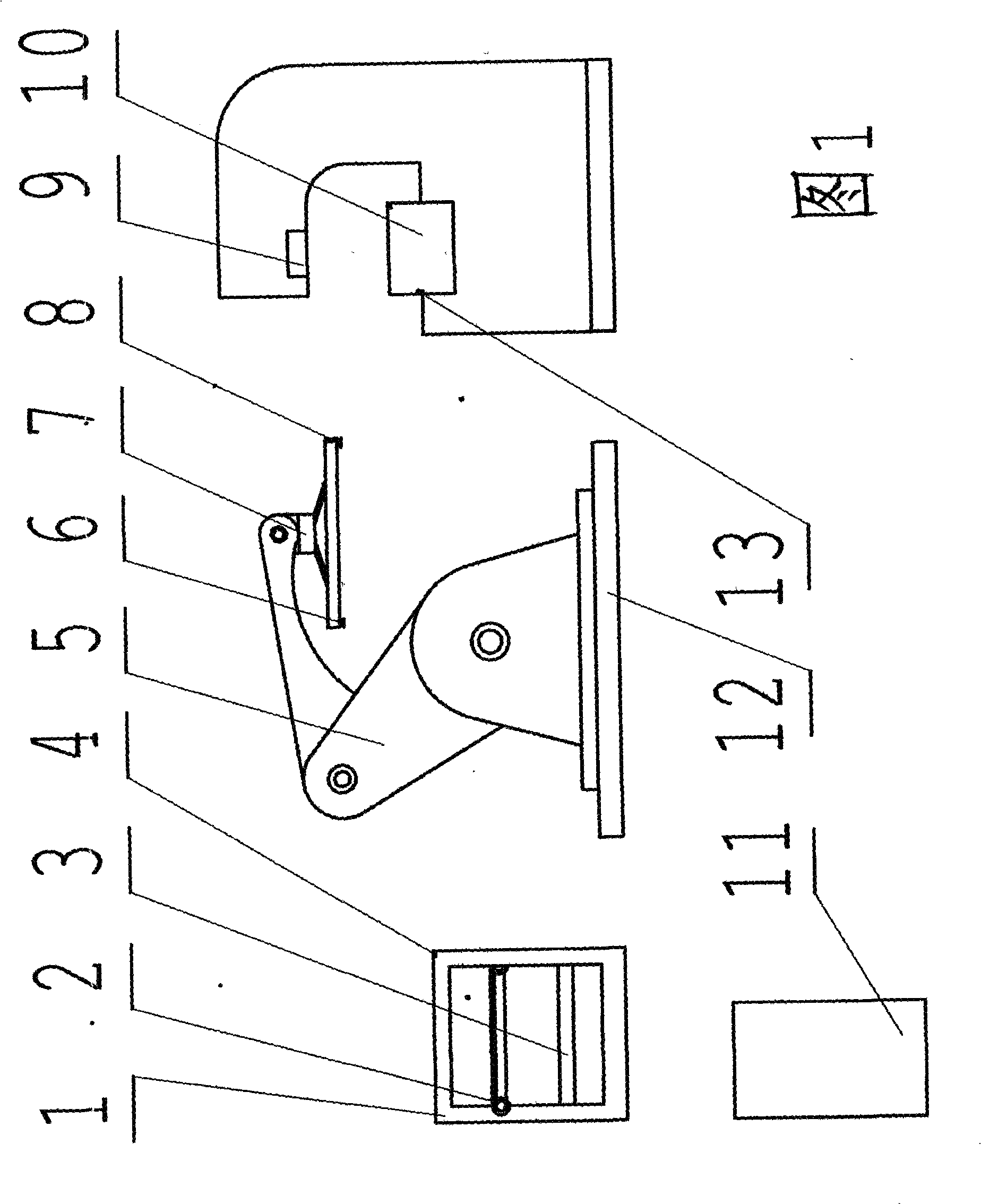

[0005] Referring to Fig. 1, an intelligent plate-supplying combination device used in an aluminum-plastic bottle cap production line is characterized in that the combination device is composed of a reclaiming manipulator unit 5, an intelligent plate-supplying platform unit 1, a quick mold changing unit 10, and an independent control operation unit 11. The adjustable base 12 of the reclaiming manipulator unit 5 is provided with a rotatable mechanical arm 7, a suction cup 6 and a sensor positioning device 8, and the intelligent plate feeding platform unit 1 is provided with an automatic lifting device 3 and a single sheet identification processing device 4 And the displacement device 2, the quick mold changing unit 10 is provided with a permanent magnet fixture 9 and a positioning device 13, the independent control and operation unit 11 is provided with a PLC controller and a touch screen, and the rotatable mechanical arm 7 is a lifting arm and a joint mechanism. The identificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com