Recovery method for galvanization process and equipment thereof

An electroplating process and recycling equipment technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems that liquid electroplating nickel cannot be recycled, increase material costs, affect metal electroplating operations, etc., to reduce the amount of cleaning, ensure recycling efficiency, The effect of reducing pollution emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Relating to the technology, means and other effects of the present invention to achieve the above-mentioned purpose, a preferred embodiment is enumerated and described in detail with accompanying drawings as follows. It is believed that the purpose, characteristics and other advantages of the present invention can be obtained from it And specific understanding.

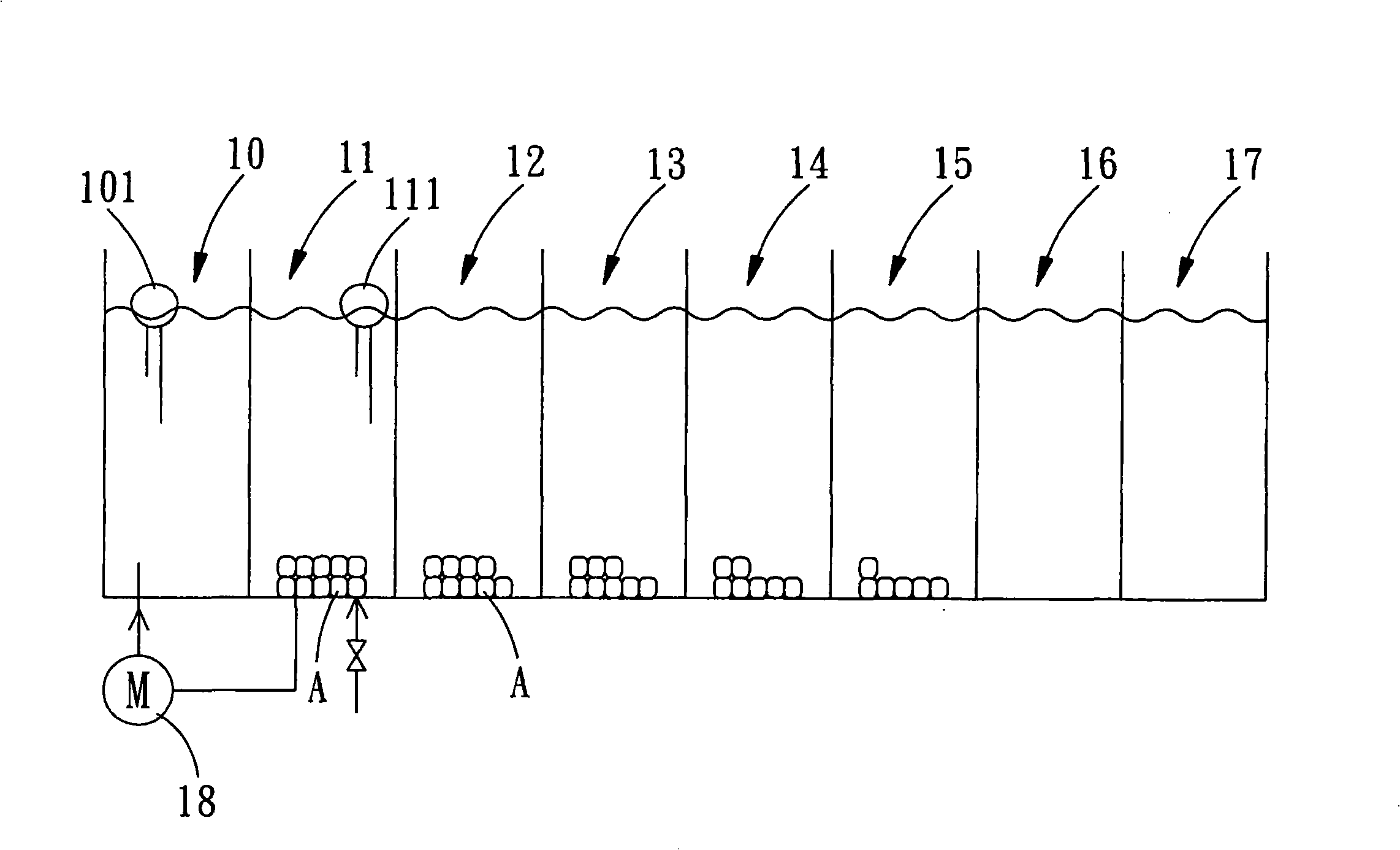

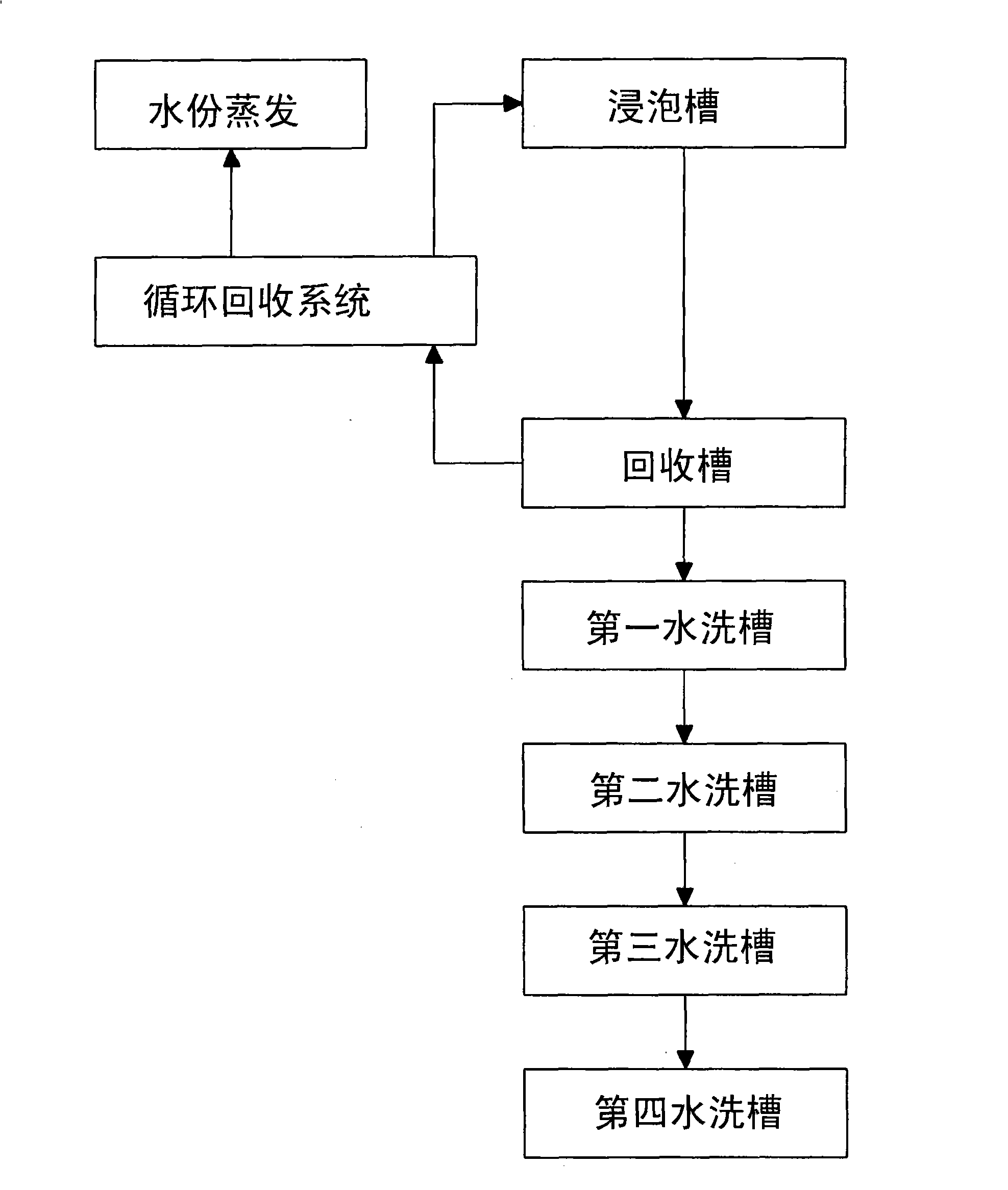

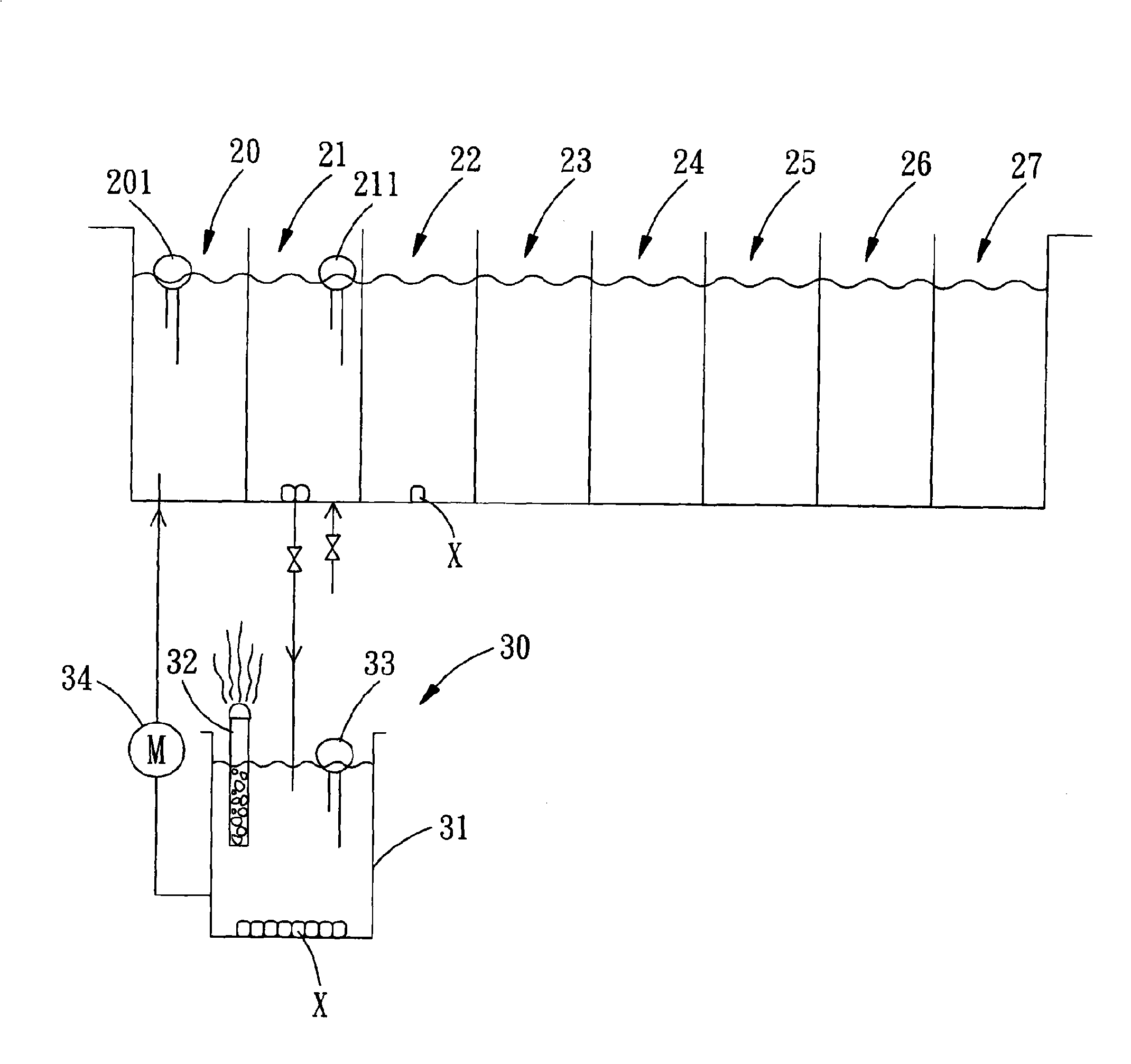

[0039] Please refer to the device embodiment of the present invention figure 2 , image 3 , the method of the present invention is to allow workpieces to be processed to pass through the immersion tank 20, the recovery tank 21, the first washing tank 22, the second washing tank 23, the third washing tank 24, the fourth washing tank with high concentration water-soluble electroplated metal one by one 25. Tin prepreg tank 26 and tin liquid tank 27, the soaking tank 20 and recovery tank 21 are equipped with water level gauges 201.211 for water level control, characterized in that:

[0040] A circulation recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com