Method for preparing ethyl alcohol with corn fermentation

A corn and ethanol technology, applied in microorganism-based methods, fermentation, biochemical equipment and methods, etc., can solve problems such as excessive corn husks, and achieve the effects of full yeast cells, suitable temperature and stable yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

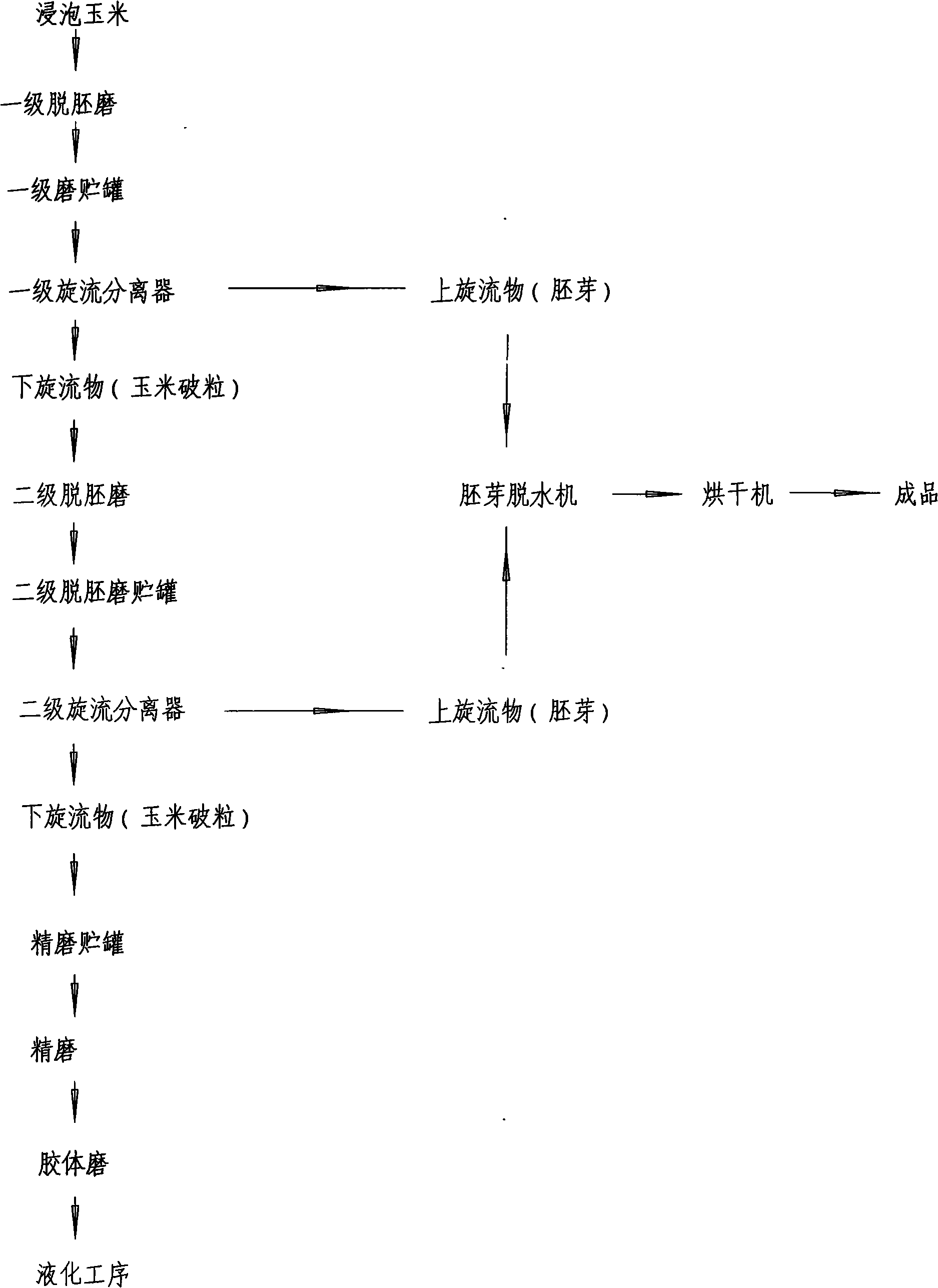

Method used

Image

Examples

Embodiment 1

[0062] 1. Purification process

[0063] The raw corn is purified by the induced draft fan, the initial cleaning sieve, and the cylinder cleaning sieve, and then transferred to the soaking tank.

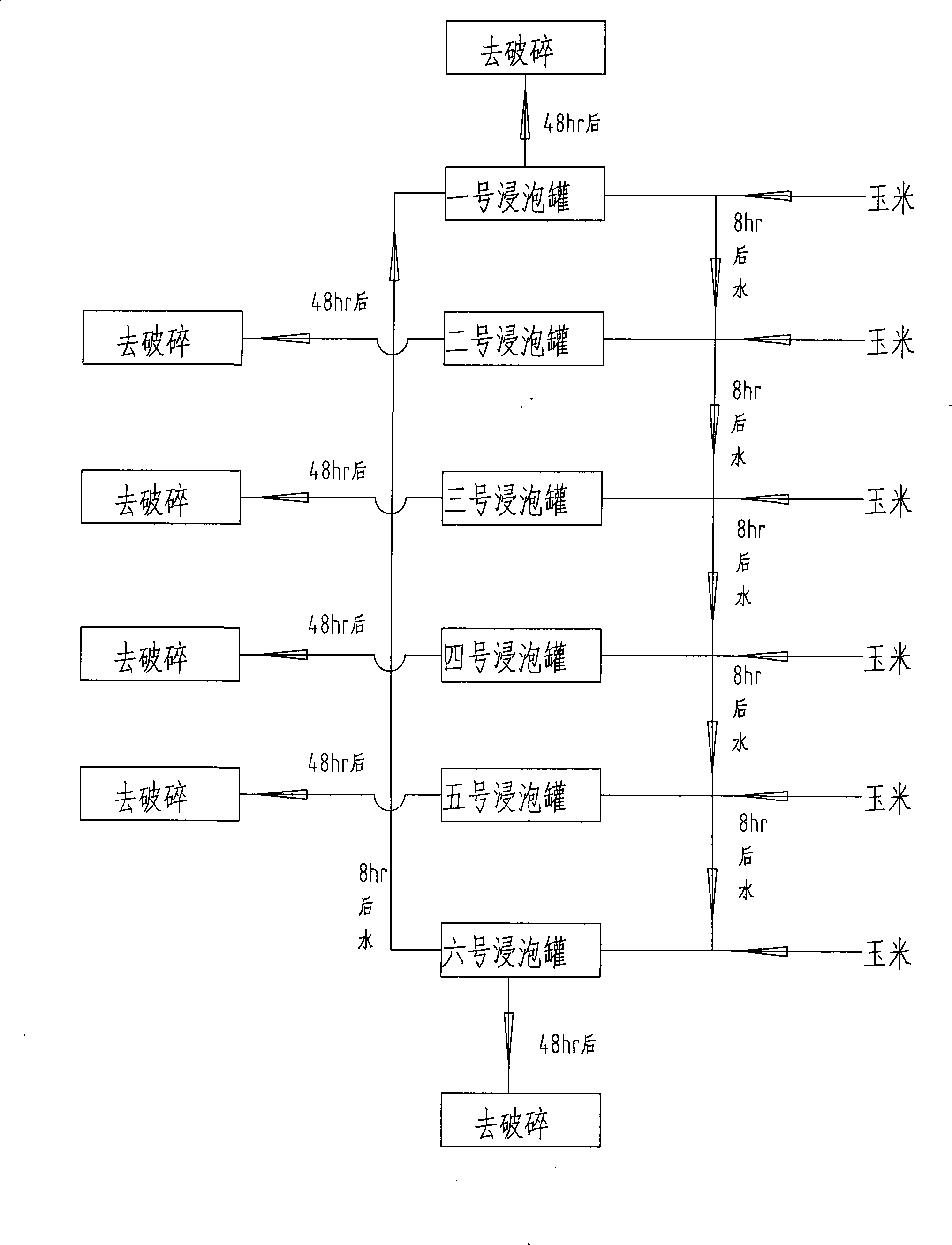

[0064] 2. Soaking process

[0065] Send water to No. 1 soaking tank, adjust the ratio of corn to delivery water between 1:3, and the corn delivery speed is 45T / h. After adding, start the circulation pump of No. 1 soaking tank to circulate the soaking water. The temperature is controlled at 50°C. After 8 hours, pour the soaking water in the No. 1 soaking tank into the No. 2 soaking tank, then add corn to the No. 2 soaking tank, and add water to the No. 2 soaking tank at the same time. The temperature of the No. 1 soaking tank is controlled at 53°C. To maintain the liquid level, after adding corn and water to No. 2 soaking tank, start the soaking water circulating pump, open the condensate valve and steam valve of the corn circulating water heat exchanger, adjust the temperature at 52°...

Embodiment 2

[0098] 1. Purification process

[0099] The raw corn is purified by the induced draft fan, the initial cleaning sieve, and the cylinder cleaning sieve, and then transferred to the soaking tank.

[0100] 2. Soaking process

[0101] Send water to No. 1 soaking tank, adjust the ratio of corn to delivery water between 1:3, and the corn delivery speed is 45T / h. After adding, start the circulation pump of No. 1 soaking tank to circulate the soaking water. The temperature is controlled at 54°C. After 8 hours, pour the soaking water in the No. 1 soaking tank into the No. 2 soaking tank, then add corn to the No. 2 soaking tank, and add water to the No. 2 soaking tank at the same time. The temperature of the No. 1 soaking tank is controlled at 54°C. To maintain the liquid level, after adding corn and water to No. 2 soaking tank, start the soaking water circulating pump, open the condensate valve and steam valve of the corn circulating water heat exchanger, adjust the temperature at 54 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com