Separation purification method and apparatus for p-benzene dicarboxylic acid

A technology of terephthalic acid and filter cake is applied in the field of separation and purification of compounds, which can solve the problems of large investment and energy consumption, high equipment investment and high maintenance cost, and achieves low equipment investment cost, low energy consumption and product quality assurance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

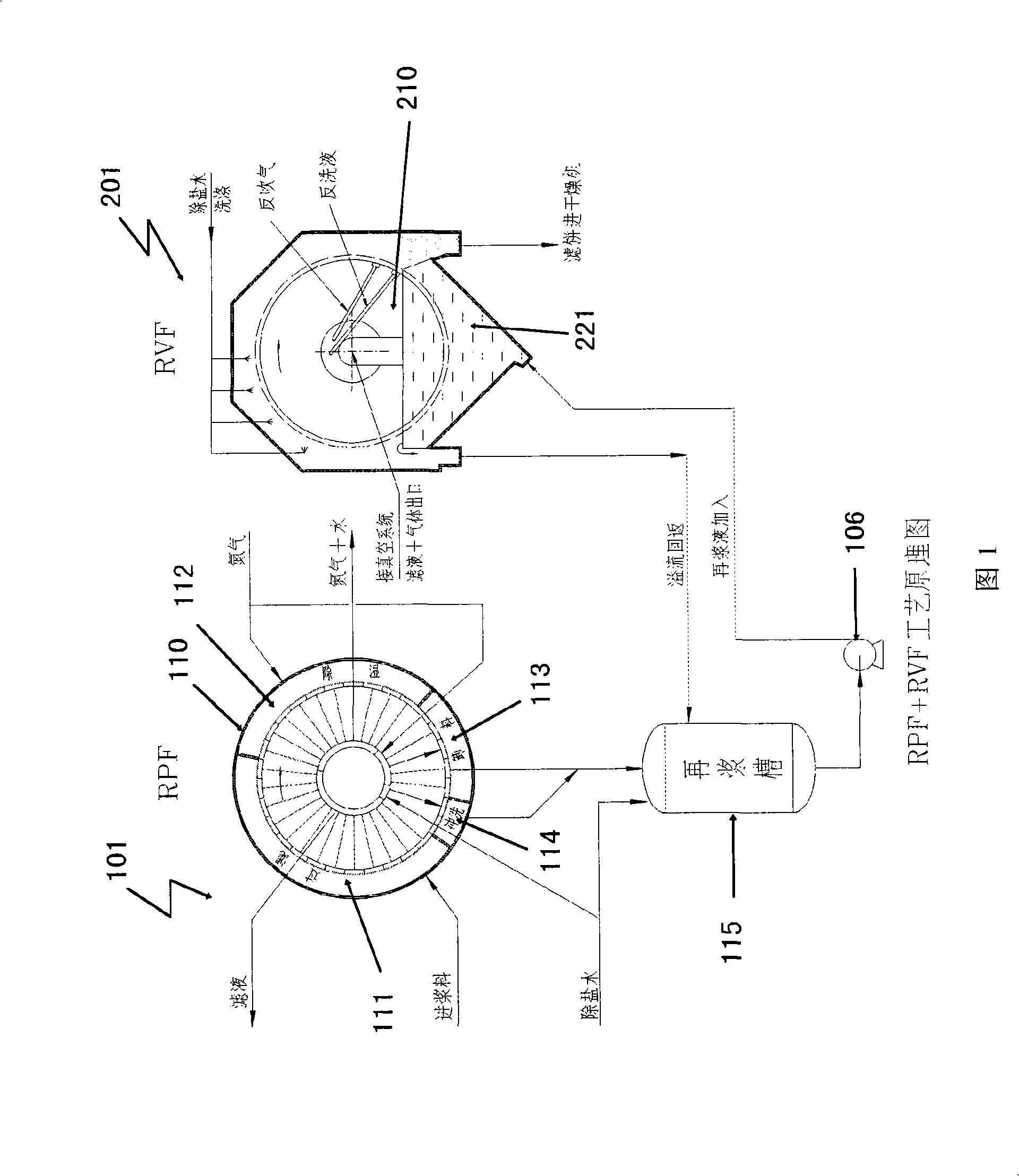

[0051] As shown in Figures 1 and 2, the solid phase content from the fourth crystallizer is ~36.5%, the viscosity is ~0.7cp, the p-TA content is ~1330ppm, the average diameter of TA particles is 110~120μm, and the pressure is 0.35MPaG , and the CTA slurry with a temperature of about 148°C was pressurized to 0.55MPaG with a pump, and then fed into the filtration zone of the rotary pressure filter. The pressure drop on both sides of the filter cloth in the filter area is maintained at about 0.15MPaG. A filter cake with a thickness of ~120mm is gradually formed in the filter zone, and the filtrate enters the filtrate tank with the same temperature and pressure as the fourth crystallizer through the conduit, and the filtrate is sent to the PTA mother liquor recovery system under liquid level control.

[0052] Inside the rotary pressure filter, the formed filter cake is transferred to the dehumidification zone by the rotation of the drum, in N 2 Dry and dehumidify under air, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com