Method for synthesizing magnesium germanide

A technology of magnesium germanium and germanium powder, applied in chemical instruments and methods, germanium compounds, inorganic chemistry, etc., can solve problems such as methods to be improved, magnesium vapor is volatile, and power consumption is large, and achieves low impurity content and reduced Energy consumption, the effect of overcoming large power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

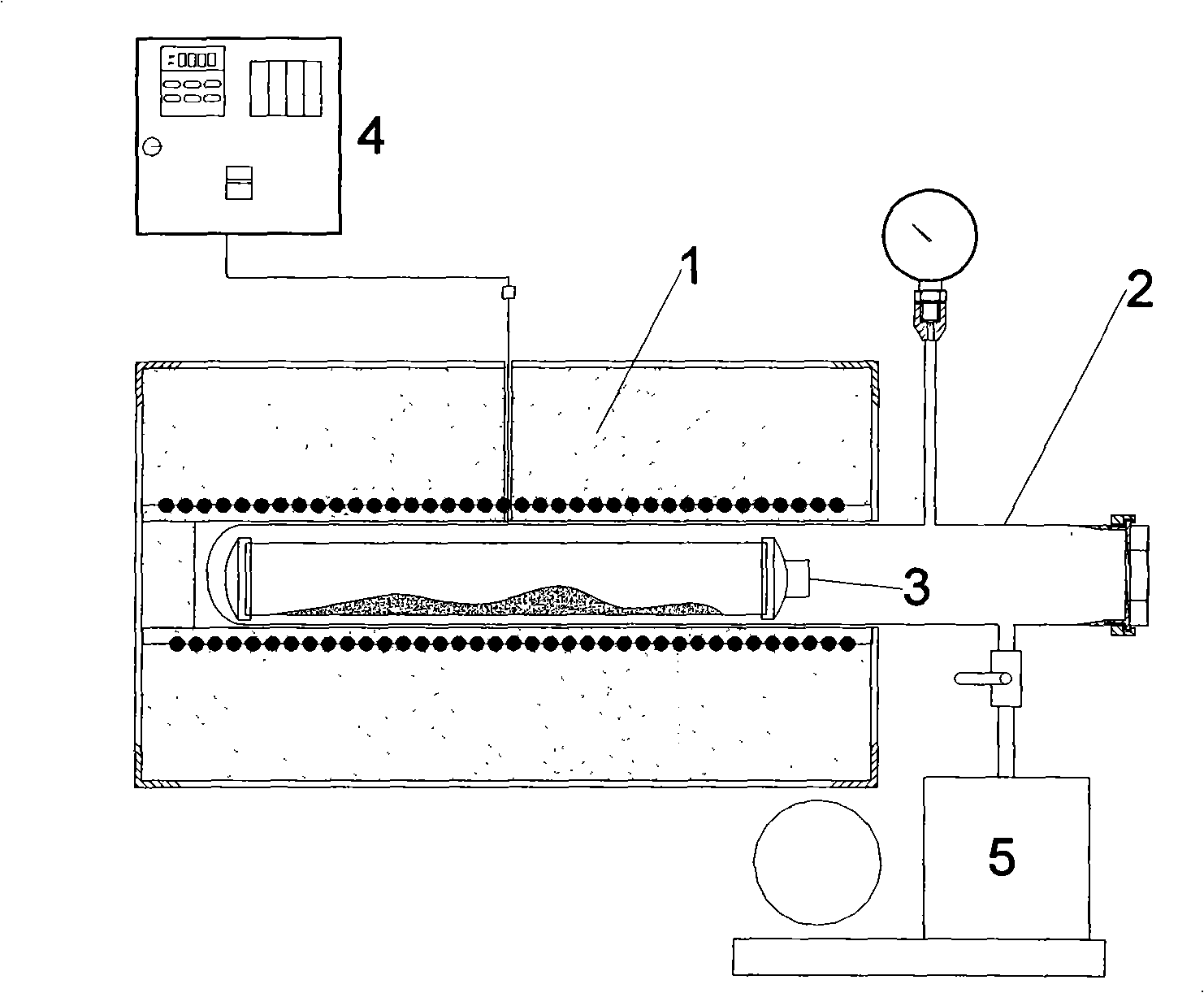

[0017] 7.261 grams of germanium powder and 4.862 grams of magnesium powder were uniformly mixed and loaded into reactor 3 and sealed. The reactor 3 is pushed into the synthesis furnace, and the furnace tube 2 is sealed with a quick-fit flange with a sealing ring. Use the mechanical pump in the vacuum system 5 to evacuate the inside of the furnace tube 2 to below 10 Pa, move it into the heating furnace 1, and start to heat up. The temperature control system 4 controls the temperature in the furnace. When the temperature reaches the synthesis temperature of 500° C., the temperature is kept for 3 hours to fully proceed the reaction, and then the heating furnace is removed and cooled naturally. Slowly put in air after cooling down, take out the product, and obtain loose blue-gray magnesium germanide powder.

Embodiment 2

[0019] 14.522 grams of germanium powder and 9.724 grams of magnesium powder were uniformly mixed and loaded into reactor 3 and sealed. The reactor 3 is pushed into the synthesis furnace, and the furnace tube 2 is sealed with a quick-fit flange with a sealing ring. Use the mechanical pump in the vacuum system 5 to evacuate the inside of the furnace tube 2 to below 10 Pa, move it into the heating furnace 1, and start to heat up. The temperature control system 4 controls the temperature in the furnace. When the temperature reaches the synthesis temperature of 550° C., keep it warm for 2 hours to fully proceed the reaction, then remove the heating furnace and let it cool naturally. Slowly put in air after cooling down, take out the product, and obtain loose blue-gray magnesium germanide powder.

Embodiment 3

[0021] 21.783 grams of germanium powder and 14.586 grams of magnesium powder were uniformly mixed and loaded into reactor 3 and sealed. The reactor 3 is pushed into the synthesis furnace, and the furnace tube 2 is sealed with a quick-fit flange with a sealing ring. Use the mechanical pump in the vacuum system 5 to evacuate the inside of the furnace tube 2 to below 10 Pa, move it into the heating furnace 1, and start to heat up. The temperature control system 4 controls the temperature in the furnace. When the temperature reaches the synthesis temperature of 600° C., keep it warm for 1 hour to fully proceed the reaction, then remove the heating furnace and let it cool naturally. Slowly put in air after cooling down, take out the product, and obtain loose blue-gray magnesium germanide powder.

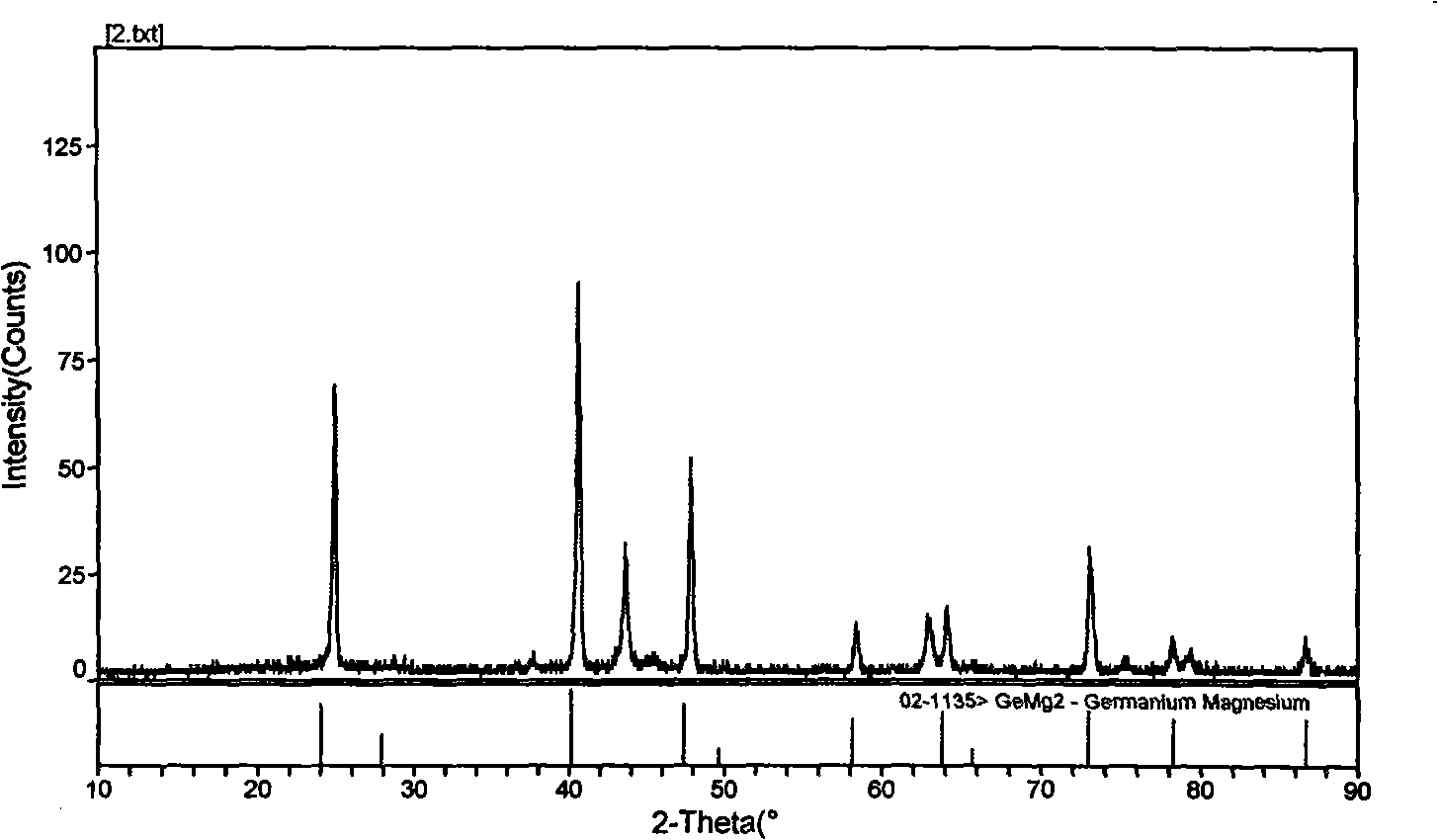

[0022] figure 2 It is the XRD spectrum pattern of the magnesium germanide synthesized in embodiment 1. It is found by comparison that the obtained magnesium germanium is consistent wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com