Belt deploying and retracting device of winch

A technology for retracting belts and winches, which is applied to motor vehicles, transportation and packaging, and vehicles used for freight transportation. It can solve the problems of common binding devices, low safety and stability, and high application costs. Achieve one-way continuous rotation, low cost of use, and high safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

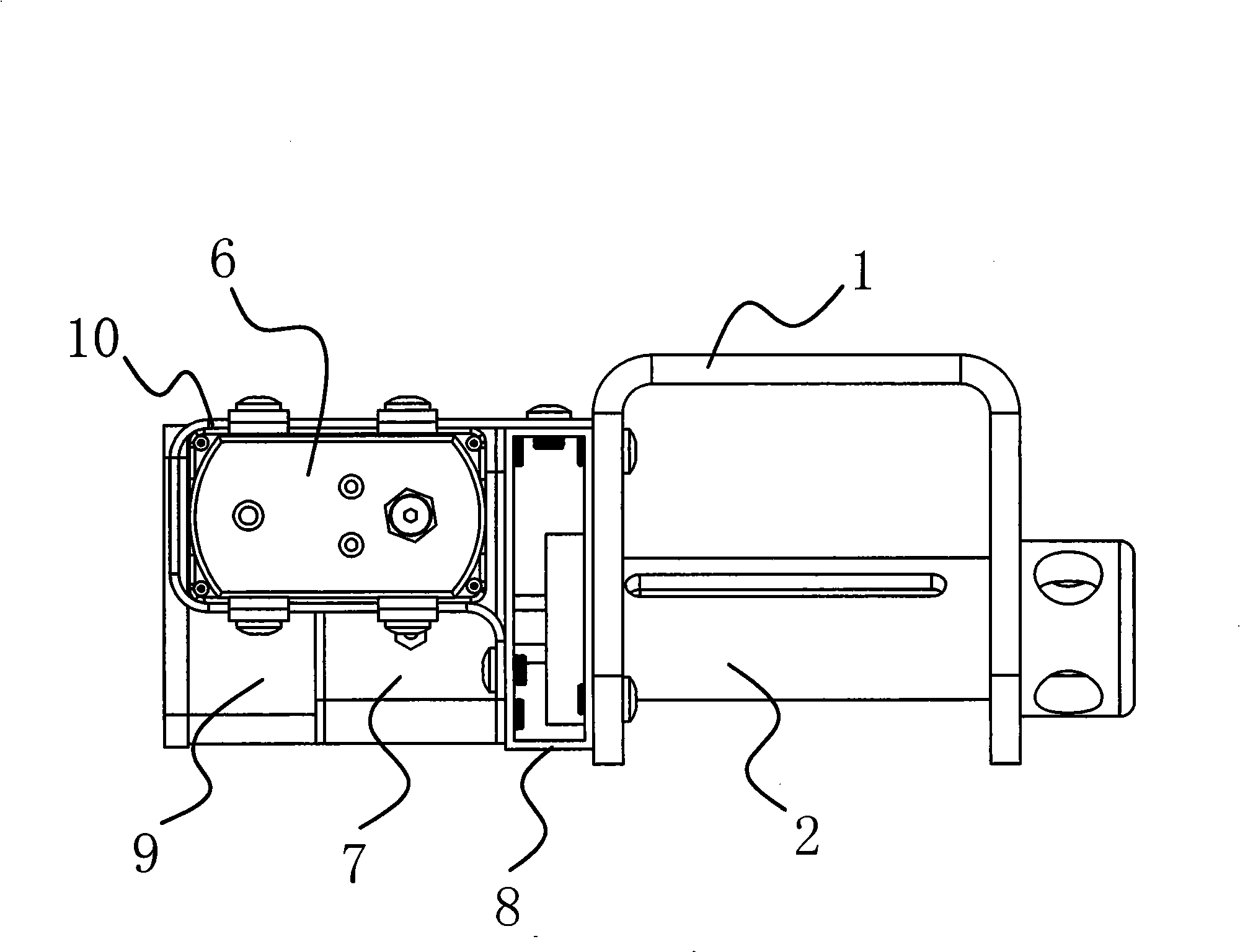

[0027] Such as figure 1 with figure 2 As shown, the winch includes a bracket 1 and a belt shaft 2 connected to the bracket 1, the belt shaft 2 can rotate relative to the bracket 1, and the belt shaft 2 is wound with a tape for binding goods. The take-up belt device of this winch is arranged on the support 1 place of the winch, and this device links with the belt shaft 2 of the winch. This device is made up of parts such as worm wheel 3, worm screw 4, driving mechanism. Wherein the drive mechanism includes a motor 5 , a control circuit for controlling the motor 5 to rotate forward or reverse or the speed of rotation, and a reduction transmission box 6 . The reduction transmission box 6 includes several gears meshing with each other.

[0028] Such as figure 2 As shown in FIG. 3 , a connection base 8 is fixedly connected to the side of the bracket 1 , the connection base 8 is fixedly connected to one end of the box body 7 , and a motor junction box 9 is fixedly connected to...

Embodiment 2

[0036] Such as Figure 4 with Figure 5 As shown, in this embodiment, the winch includes a bracket 1 and a belt shaft 2 connected to the bracket 1, the belt shaft 2 can rotate relative to the bracket 1, and a coil belt for binding goods is wound on the belt shaft 2 . One end of the belt shaft 2 is provided with a rod hole 22 for inserting a crowbar, and the other end is fixedly connected with a ratchet 15, and the side of the ratchet 15 is provided with a ratchet 16 hinged on the bracket 1, and the ratchet 16 is embedded in the ratchet 15. between the ratchets. A spring is provided between the ratchet 16 and the bracket 1 , and the control ratchet 16 is embedded between the ratchets under the action of the elastic force of the spring. The take-up belt device of this winch is arranged on the support 1 place of the winch, and this device is connected with an end that ratchet 15 is housed with the winch belt shaft 2. This device is made up of components such as worm gear 3, w...

Embodiment 3

[0043] As shown in FIG. 7 , in this embodiment, the winch includes a bracket 1 , a belt shaft 2 , and a coil belt for binding goods is wound on the belt shaft 2 , without a ratchet 15 , a pawl 16 and a spring. The rest are the same as in Example 2, and will not be repeated herein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com