Jetting-moulding screw of plastic jetting-moulding machine

An injection molding machine and screw technology, applied in the field of injection molding screws, can solve problems such as poor contact of contact surfaces, non-alignment of annular non-return screw heads, and increased closing time, so as to improve closing efficiency and speed, reduce material stagnation, and resistance Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

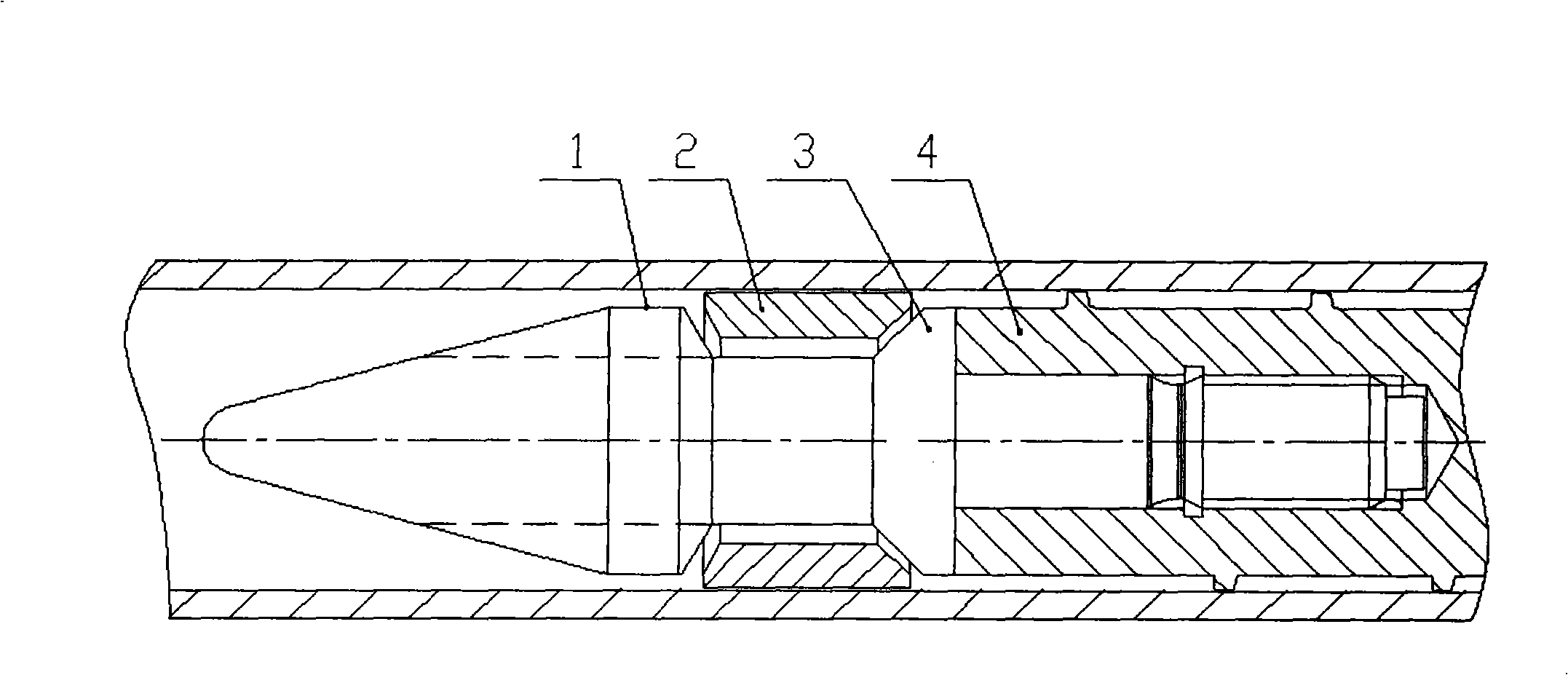

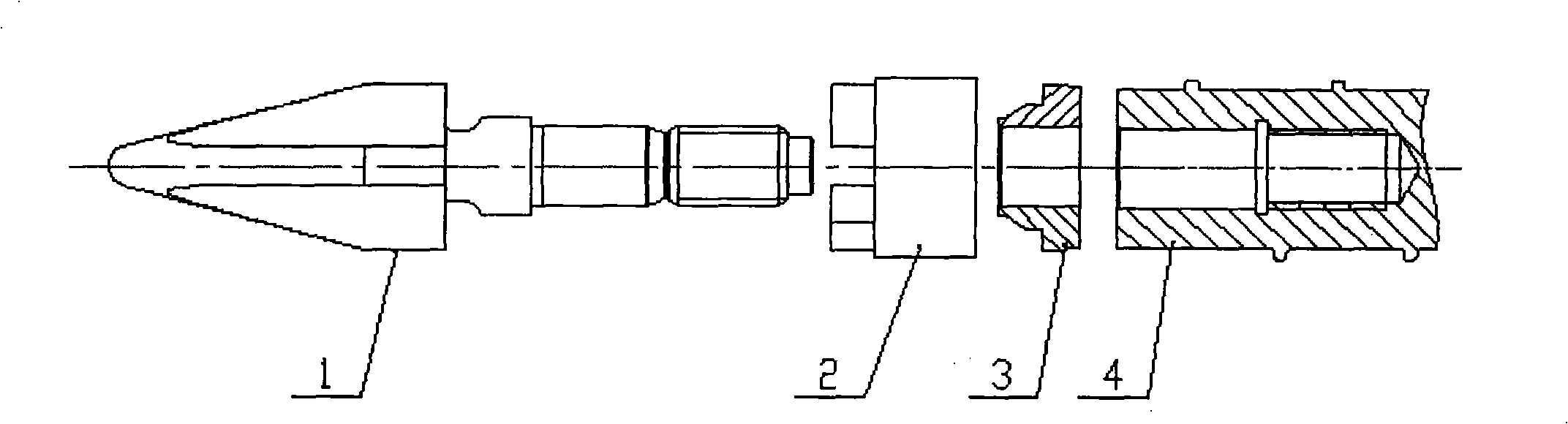

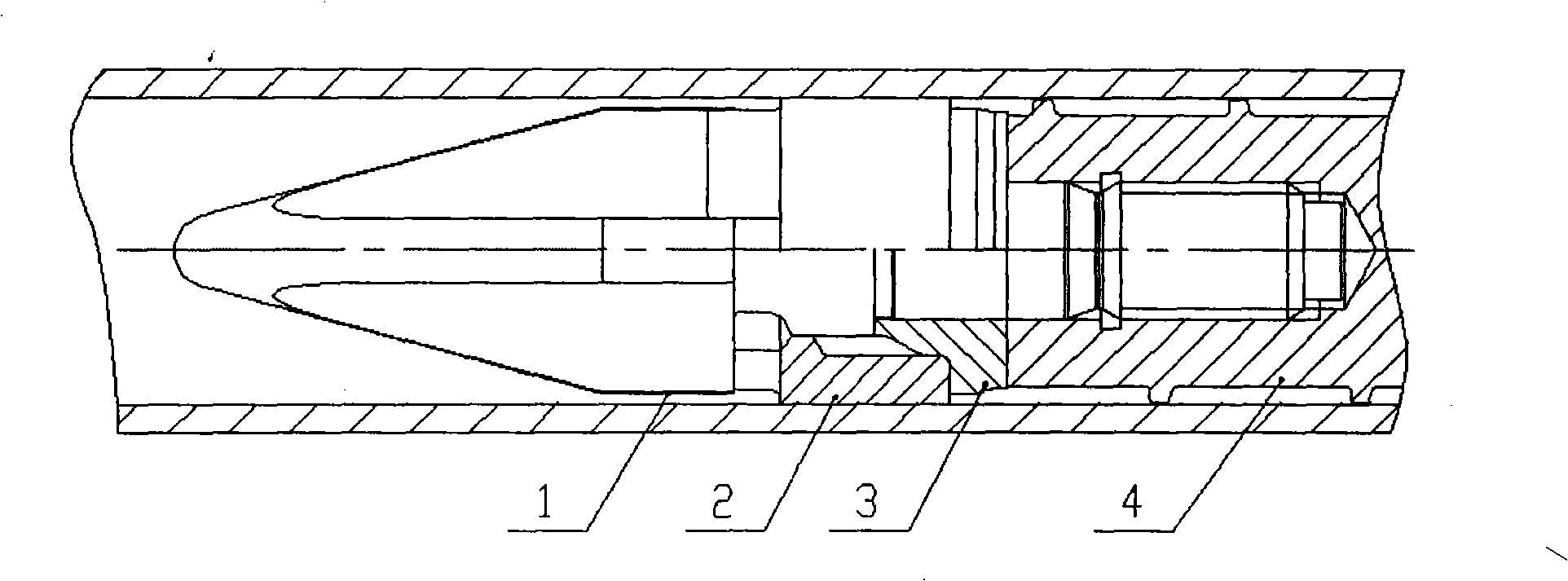

[0025] The non-return screw head of the screw of the present invention is a sliding type non-return screw head, and the screw is mainly composed of four parts, such as figure 2 As shown, they are screw head 1, check ring 2, thrust ring 3 and screw body 4 respectively. When assembling, put the non-return ring 2 between the screw head 1 and the thrust ring 3, the thread 12 on the screw head is connected with the internal thread at the left end of the screw body 4, and the screw head is connected with the left end of the internal thread of the screw body 4 through the positioning cylinder 13 The fixed surface realizes the positioning, and the combination is as follows image 3 and Figure 4 shown, and then placed in the barrel of the injection molding machine. The structure of the screw head 1 is as Figure 5 As shown, it is mainly composed of a conical head 5, a cylinder 8, a positioning cylinder 13 and a connecting thread 12 and the like. Four axial flow channels 6 are ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com