Method for manufacturing primary composite multi-layer wood floor

A production method and technology for solid wood floors, applied in the direction of adhesive types, wood processing appliances, aldehyde/ketone condensation polymer adhesives, etc., can solve the problems of wasting manpower, reducing production efficiency, floor warping, etc. Processing steps, reduced warpage, optimal strength and elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

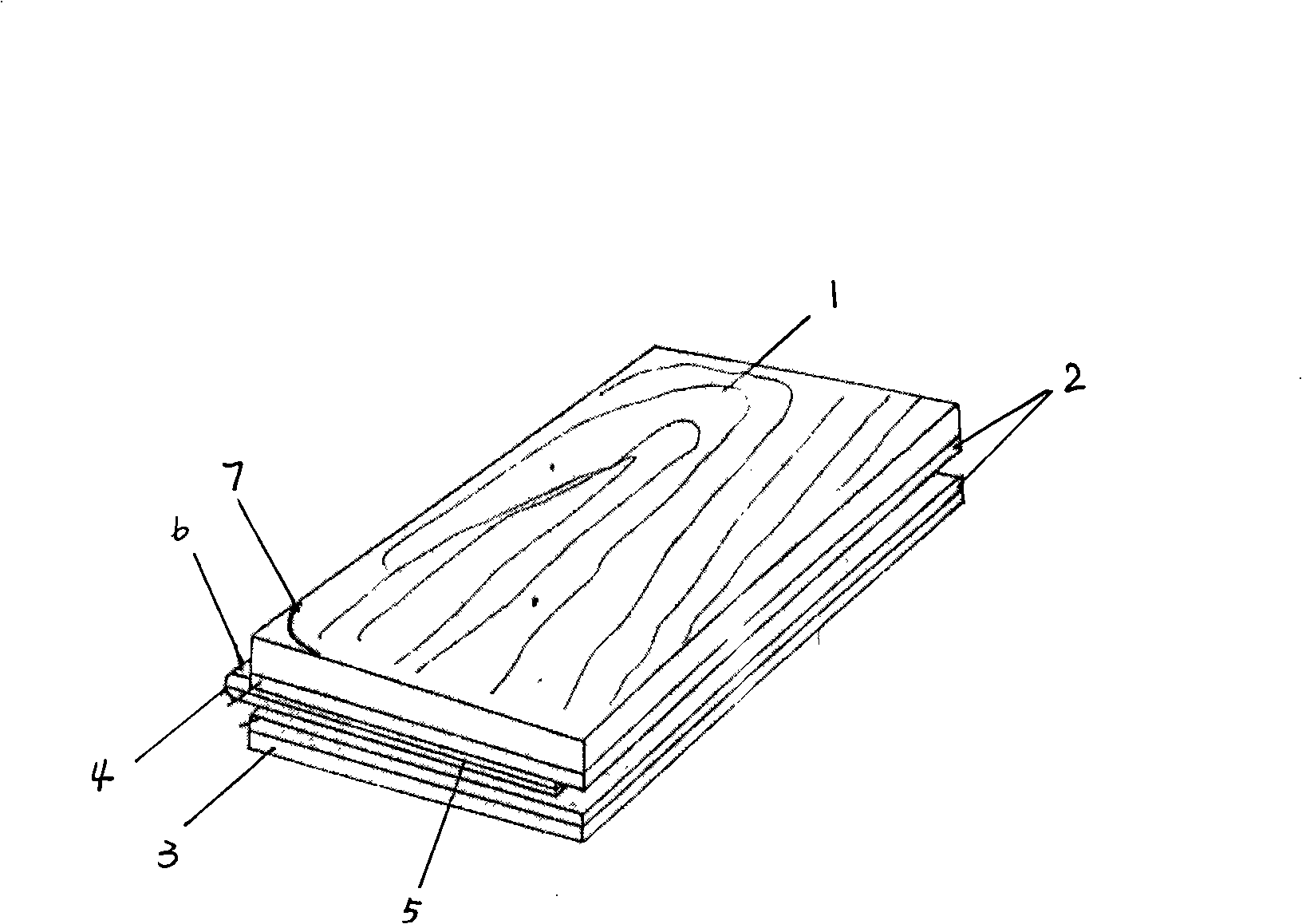

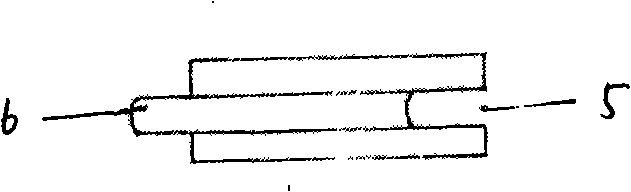

[0021] Below in conjunction with accompanying drawing, the present invention will be further described: as figure 1 , 2 As shown, the production method of one-time composite multi-layer solid wood composite flooring, its specific production method is as follows:

[0022] 1. Preparation of phenolic resin

[0023] ① The ratio of raw materials: phenol: formaldehyde: caustic soda = 1: 2.0: 0.58

[0024] ②Put the melted phenol into the reaction kettle, start the stirring blade, add caustic soda once, cool down, and keep the heat at 40-50°C.

[0025] ③Add formaldehyde (80% of the total amount) once, control the temperature at about 50°C, start timing at 40°C for 50-60 minutes, and keep warm for 1 hour when the temperature rises to 93°C.

[0026] ④ When the viscosity is between 90 and 93°C, start to measure the viscosity. When the viscosity of the liquid is 25±2S / 30°C, add secondary formaldehyde water.

[0027] ⑤ When the temperature reaches 75°C, add secondary caustic soda and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com