Post-treatement method for PVA (polyvinyl alcohol) jelly glue fibre

A polyvinyl alcohol and fiber technology, which is applied in the field of post-treatment of PVA jelly fibers, can solve problems such as increased procedures, energy consumption, environmental pollution, and increased production costs, and achieves low solvent residual rate, good tensile performance, and reduced The effect of cost recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

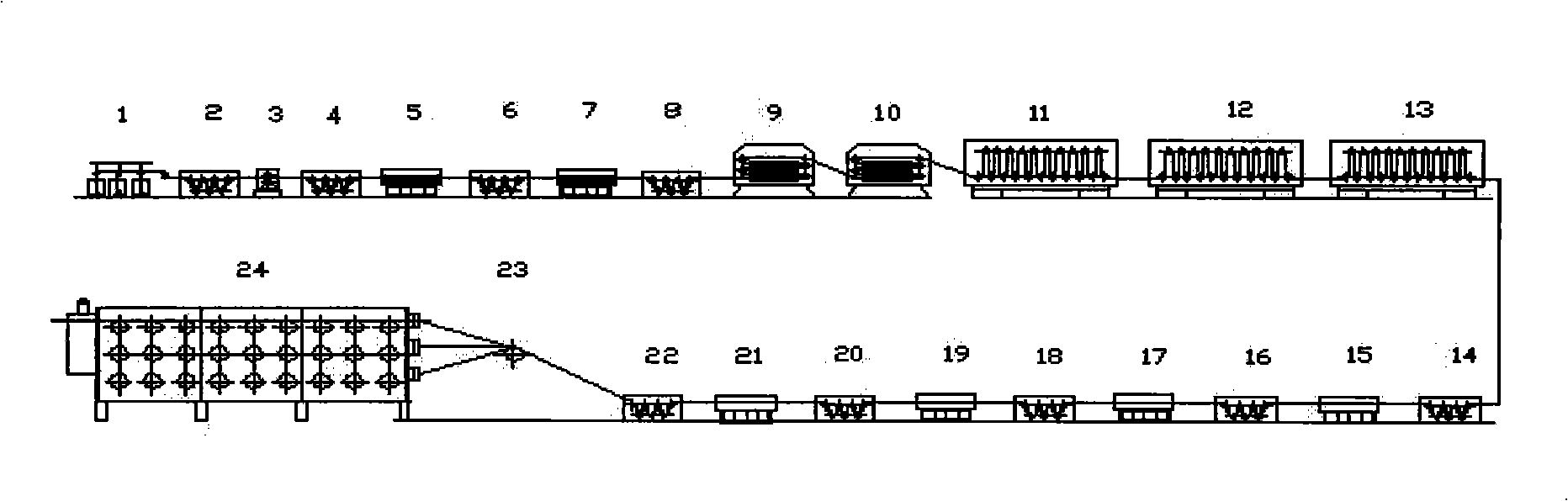

Image

Examples

Embodiment 1

[0023] PVA jelly fiber, polymerization degree 1750, PVA concentration 20%, diameter 2.5mm, solvent 40:60 water / dimethyl sulfoxide (DMSO) system, pre-stretching ratio 2 times, after hydraulic treatment, after two stages After washing and stretching, the stretching ratio is 2.5, and then sent to the continuous two-stage negative pressure extraction of the solvent in the fiber, the vacuum degree is maintained at 500Pa, after three dryings, it is stretched through a four-stage hot air oven, and the total stretching ratio is 12 times, and finally the fiber is wound to obtain the finished fiber. Fiber strength 11.5CN / dtex, modulus 260CN / dtex.

Embodiment 2

[0025] PVA jelly fiber, polymerization degree 1750, PVA concentration 20%, diameter 2.5mm, solvent 40:60 water / DMSO system, pre-stretching ratio 2 times, after hydraulic treatment, after two-stage washing and stretching, The stretching ratio is about 2.5, and then sent to the intermittent two-stage negative pressure extraction of the solvent in the fiber, the vacuum degree is maintained at 100Pa, after three dryings, it is stretched in a four-stage hot air oven, the total stretching ratio is 14, and finally the fiber roll Winding to get the finished fiber. Fiber strength 12CN / dtex, modulus 280CN / dtex.

Embodiment 3

[0027] The degree of polymerization is 1750, the concentration of PVA is 20%, the diameter is 2.5mm, the solvent is the water / DMSO system of 40:60, the pre-stretch ratio is 2 times, after the pressure-liquid treatment, after two-stage washing and stretching, the stretch ratio is 2.5 Then send the solvent in the continuous two-stage negative pressure extraction fiber, the vacuum degree is maintained at 1000Pa, the extracted fiber is dried in a hot air box, after three dryings, it is stretched in a four-stage hot air oven, and the total stretching ratio is 10. Finally, the fiber is wound to obtain the product fiber. Fiber strength 11CN / dtex, modulus 240CN / dtex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com